Side compression type ultrasound grinding and polishing device, and method thereof

A polishing device and ultrasonic technology are applied in the fields of ultrasonic grinding and polishing devices and side-pressure ultrasonic grinding and polishing devices to achieve the effects of stable performance, reduced frequency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

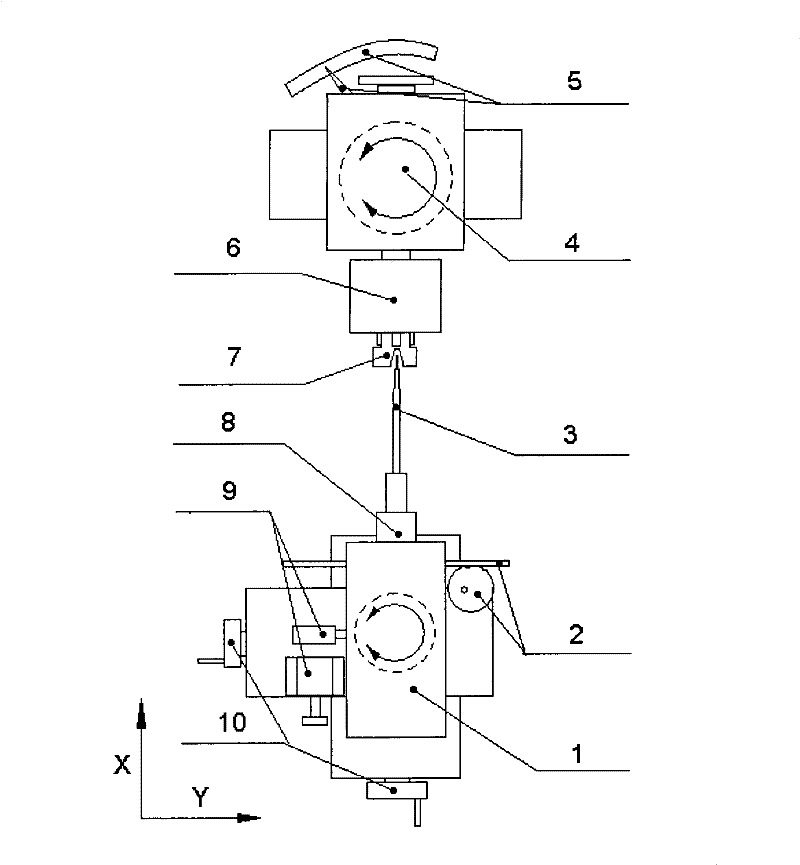

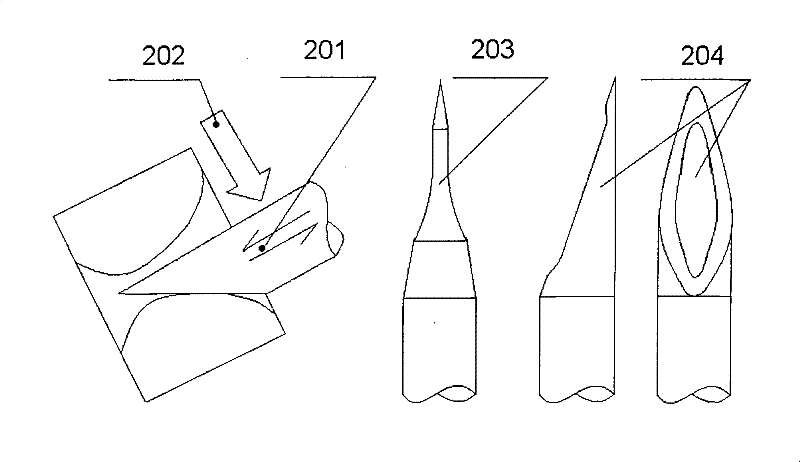

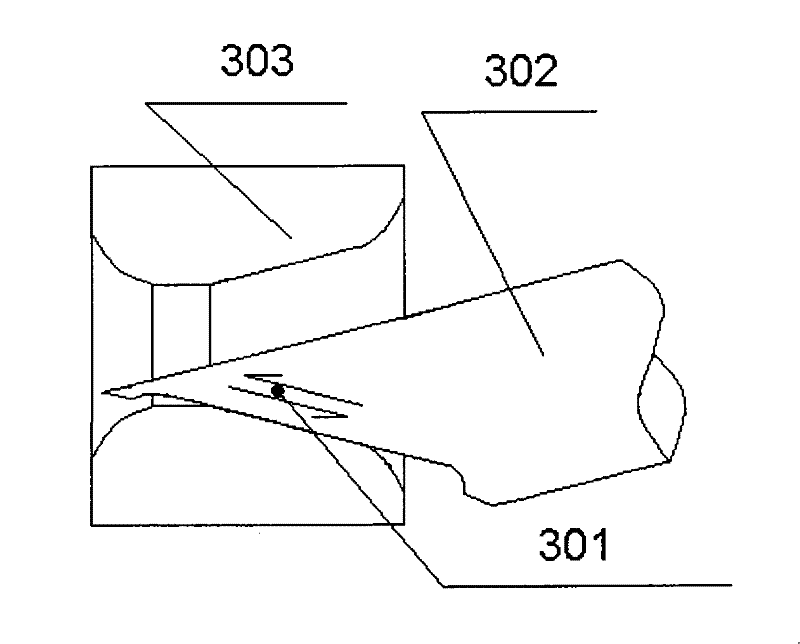

[0028] As mentioned above, all the working pressures of the existing ultrasonic grinding and polishing machines adopt the positive pressure type, that is, the pressure direction between the tool needle and the workpiece is parallel to the vibration direction of the ultrasonic longitudinal wave. In the present invention, the working pressure direction of the ultrasonic machining of the existing grinding machine is changed to the side direction, that is, it is perpendicular to the vibration direction of the ultrasonic longitudinal wave, so that the side of the tool needle is close to the machined surface of the inner hole of the mold. On this basis, increase the reciprocating swing of the tool needle. During the machining process, the tool needle and the contact surface of the workpiece are always kept in relative motion. In order to make the processing not be affected by the grinding accuracy of the tool needle, the side pressure ultrasonic grinding and polishing device also ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com