Paper cutting method and mechanism of rewinder

A rewinding machine and paper breaking technology, which is applied in the field of rewinding machines, can solve the problems of complex paper breaking mechanism, high manufacturing and assembly precision requirements, and difficulties, so as to reduce production cost and installation difficulty, low manufacturing and assembly accuracy, The effect of eliminating the trimming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

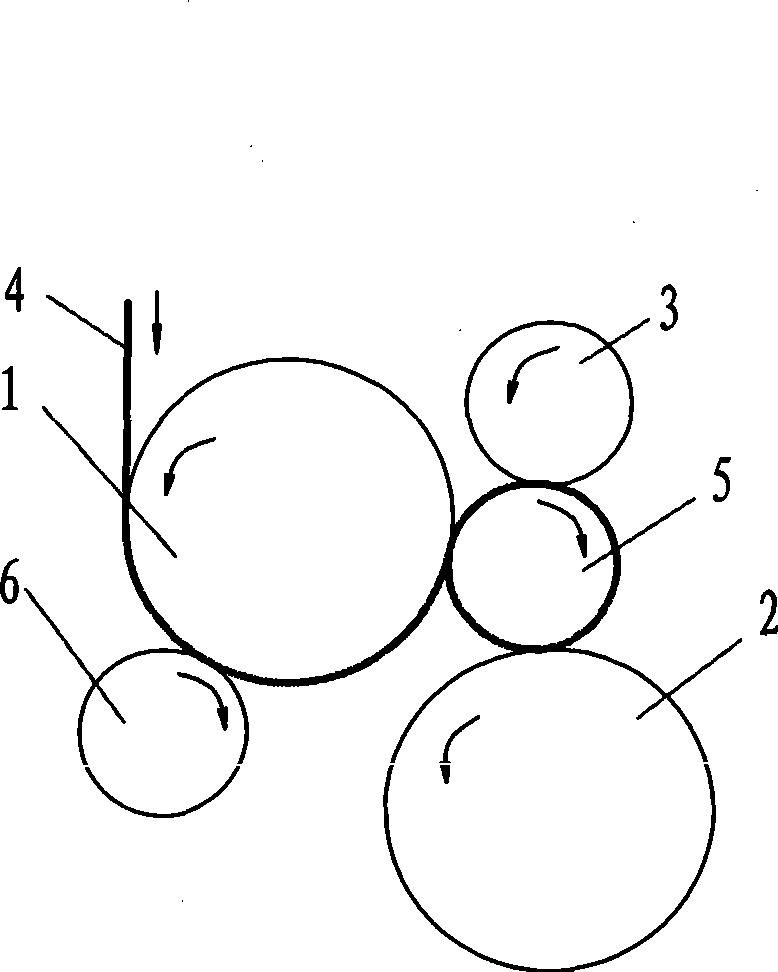

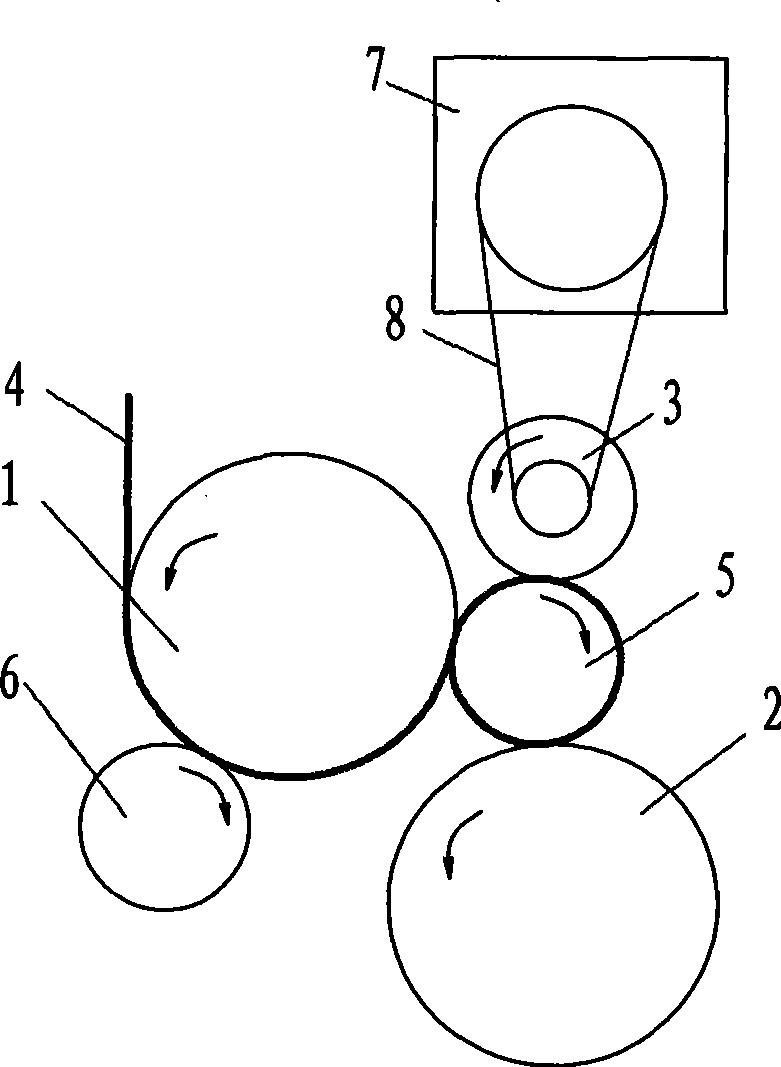

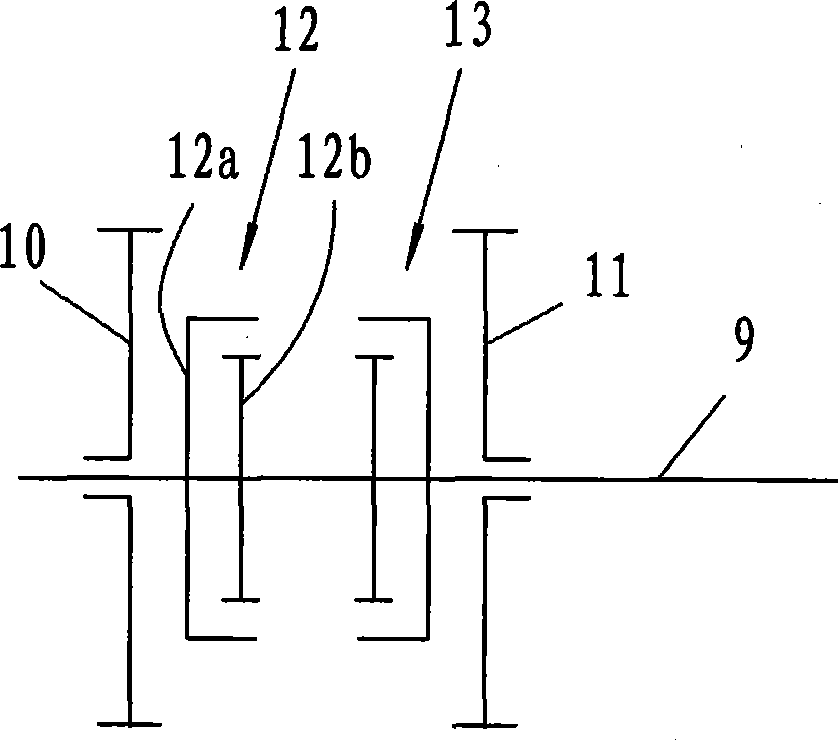

[0011] The working principle of the inventive method is as figure 1 As shown, the paper roll is rotated by three driving rollers of the rewinding machine. One of the driving rollers 1 can be called the upper rewinding roller, and the other driving roller 2 can be called the lower rewinding roller. There is also a driving roller 3 can be called the platen roller. The three drive rollers are driven to rotate by the power mechanism of the rewinder, and maintain the same outer peripheral speed. The three driving rollers rewind the paper 4 into a paper roll 5 with a certain thickness together. Another guide roller 6 sandwiches the paper 4 between the guide roller 6 and the rewinding upper roller 1 to play the role of pulling the paper to run. figure 1 in (including figure 2 ) Each arrow indicates the rotation direction of each roller, the rotation direction of the paper roll, and the running direction of the paper respectively. When the paper is broken, make one of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com