A flash-free hot die forging process for front shell forgings of automobile differential

A technology of automobile differential and forming process, applied in the field of forging, can solve the problems of shallow upper mold cavity, easy production of defective products, and difficulty in checking forging errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings:

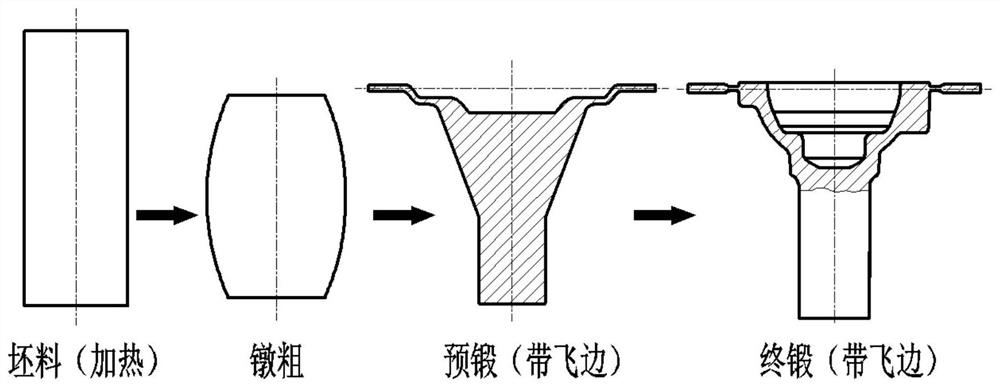

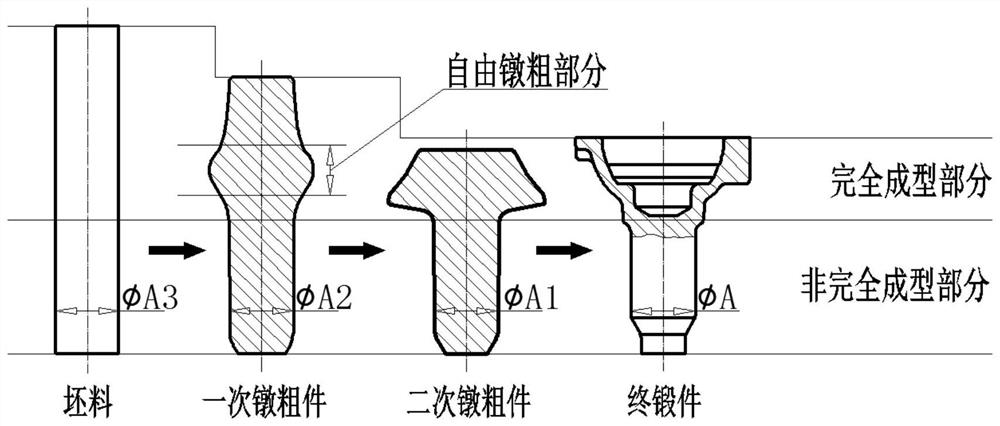

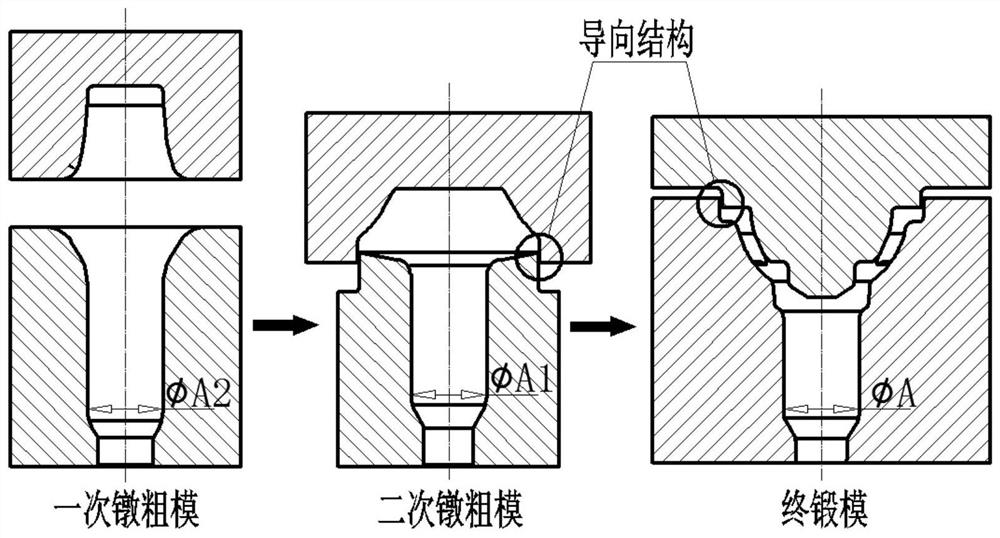

[0034] The automotive differential front case forgings provided by the present invention have no flying thermometer forged forming process, drawing on the formation characteristics of the step forging machine, making the final fractal distribution more accurate, realizing the bar material beyond the rough The ratio of upset is not bent. Drawing of process forming steps in the present invention figure 2 Image: Blast - a Upsetting Parts - Secondary Upset - Final Forging. Using the secondary molding, it is guaranteed that the upsetting is not deformable, and this forming process is applied, and the unfolded refined forging forming of the complex shell is perfect.

[0035] In order to be able to achieve the forming of the tail end of the forged rod, there is a need to select a bar with a diameter thereof, so that the long diameter of the blank is much greater than 2.5 (when free upset, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com