Method and apparatus for configuring multifunctional electrolytic set tools wagon

A multifunctional unit and configuration device technology, which is applied to cranes, transportation and packaging, and traveling bridge cranes, etc., can solve problems such as restricting the competitiveness of electrolysis multifunctional units, inconvenient operation for operators, and inability to operate tools for positioning. To achieve the effect of novel product structure and appearance, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

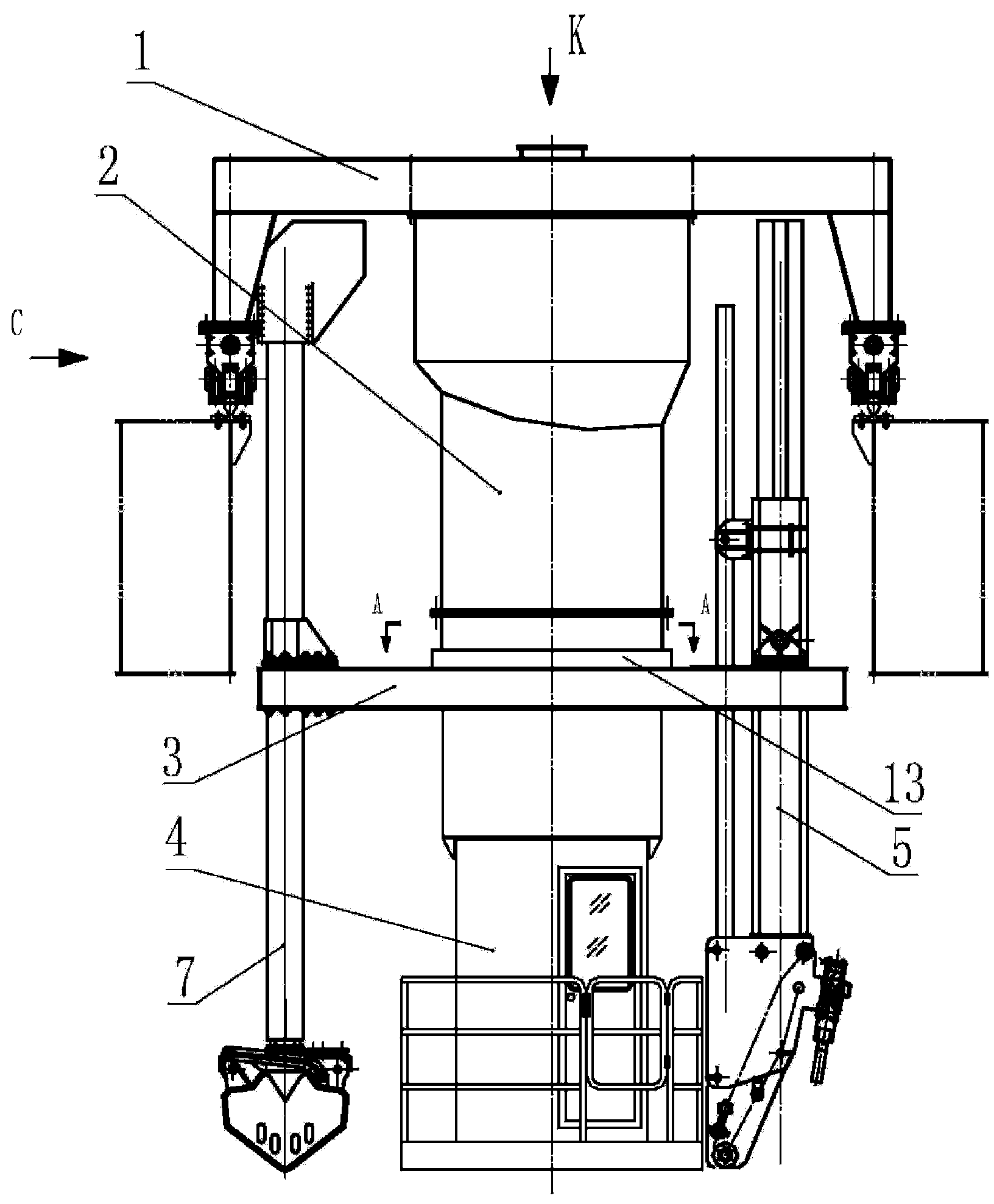

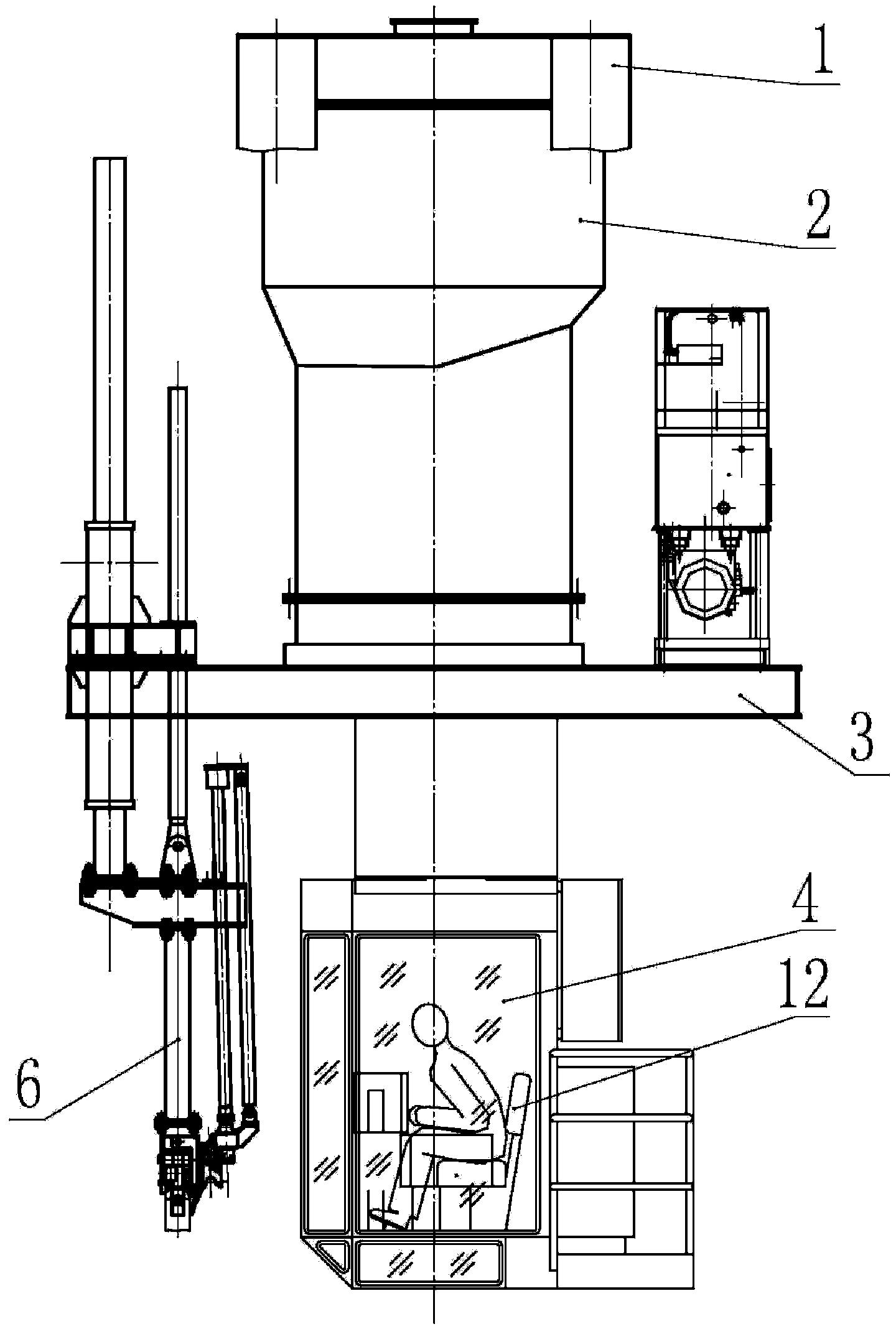

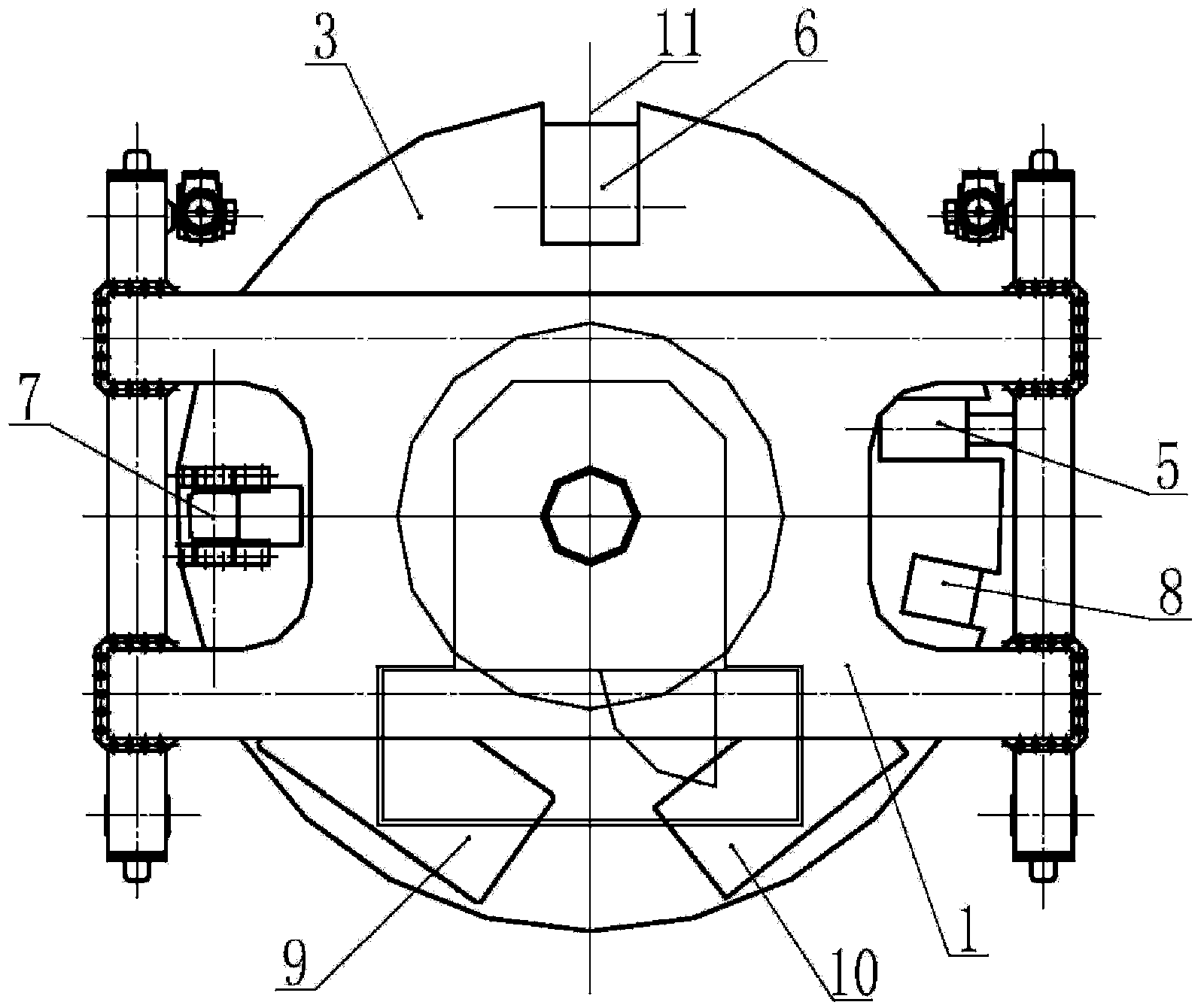

[0020] The tool trolley for the electrolytic multifunctional unit of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

[0021] Embodiment of the present invention: when making the tool trolley of the electrolytic multifunctional unit, it is produced according to a configuration method of the tool trolley of the electrolytic multifunctional unit of the present invention, that is, the material box is fixed on the frame of the tool trolley of the electrolytic multifunctional unit, The material box is fixed in the center of the tool trolley and cannot be rotated, and a rotatable tool turntable is set at the lower part of the material box, and the control room is fixed below the tool turntable so that the center line of the control room is located on the rotation center line of the tool turntable. It can rotate together with the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com