Impact damping material. helmet and panel incorporating the same

An impact damping and helmet technology, applied in the direction of helmet, helmet cover, thin material processing, etc., can solve problems such as excessively large helmets and reduced available space for panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

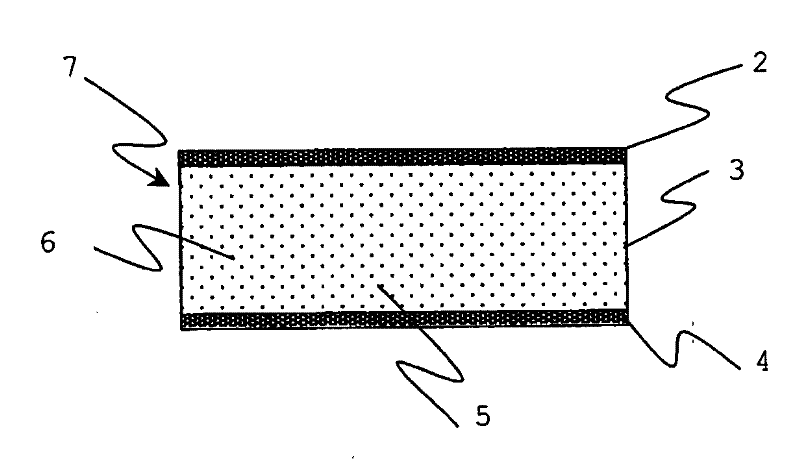

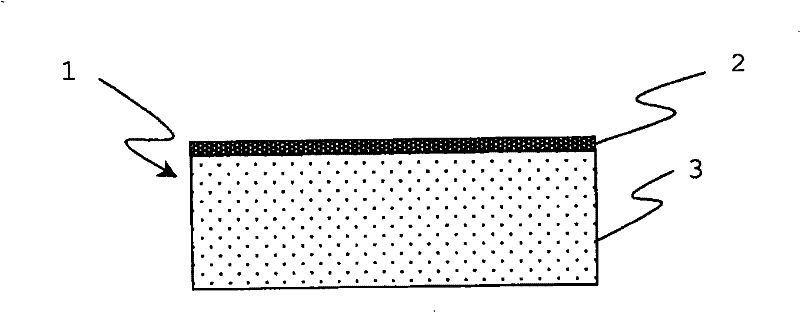

[0021] In a preferred embodiment, figure 1 The shown sandwich material 7 for impact damping according to the invention is used in the image 3 The helmet 8 in.

[0022] figure 1 The interlayer material 7 in includes a first layer 2 that distributes the load and has low air permeability. The interlayer material also comprises a second layer 3 having, for example, semi-closed microcellular structure particles 6 which are connected to each other and allow gas to flow in the gas channels 5 between the particles when the interlayer material is compressed . The cells are elastic to provide the compressibility of the sandwich material. The second layer may also provide viscous damping. A third layer 4 with low air permeability may further offer the possibility of directing the flow of gas from the compressed location to the volume around the compressed area in the second layer 3 . The third layer 4 faces the user's head, with possibly further layers between the third layer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com