Stepless yielding fabricated retaining wall supporting system and construction method

A prefabricated and retaining wall technology, applied in the fields of botanical equipment and methods, artificial islands, water conservancy projects, etc., can solve the problem of easy shearing, overturning and slippage, the site is difficult to meet on-site pouring, and does not have the function of letting pressure. and other problems, to achieve the effect of improving stability and safety, preventing overturning and breaking, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

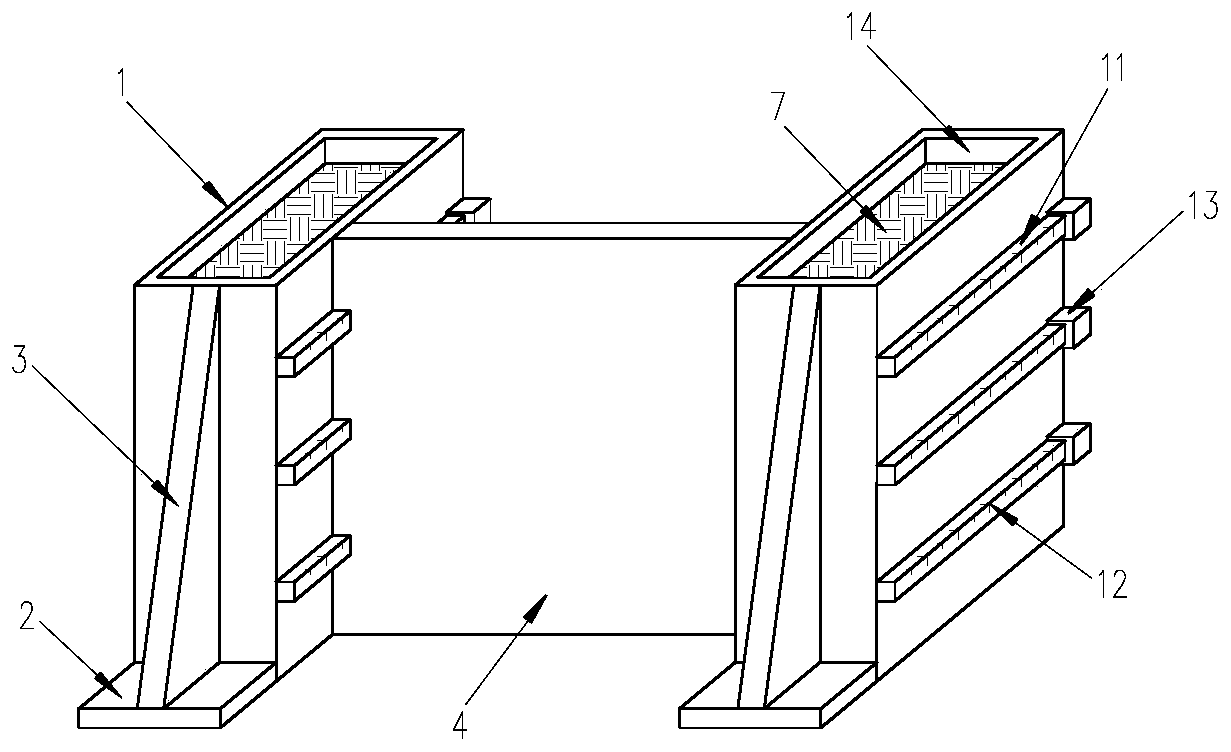

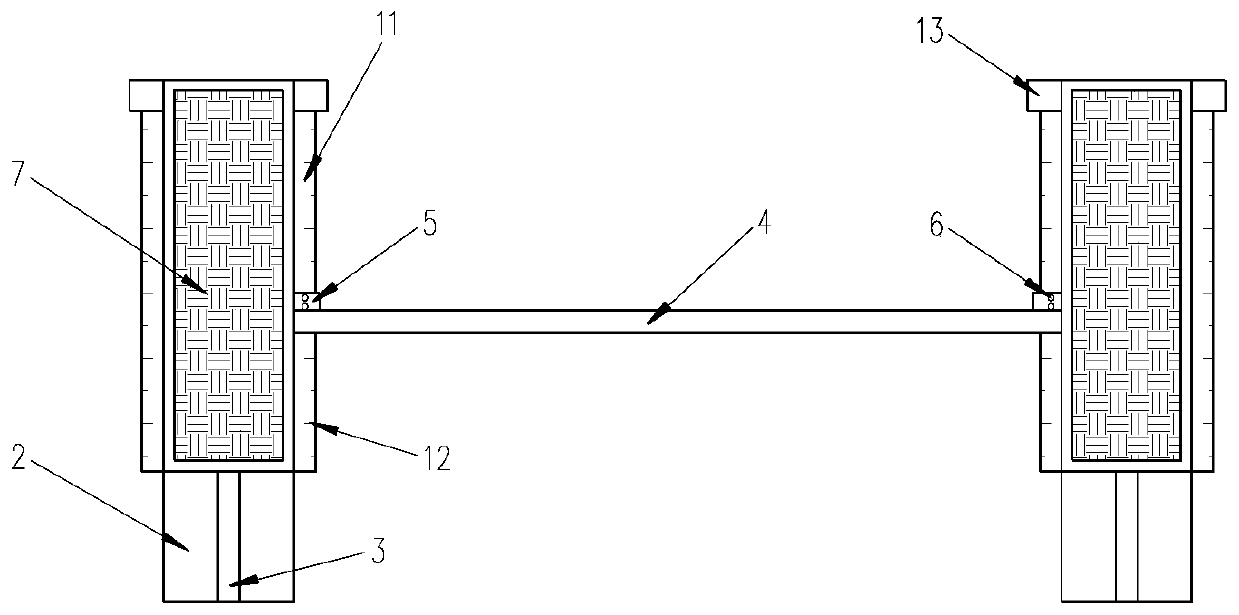

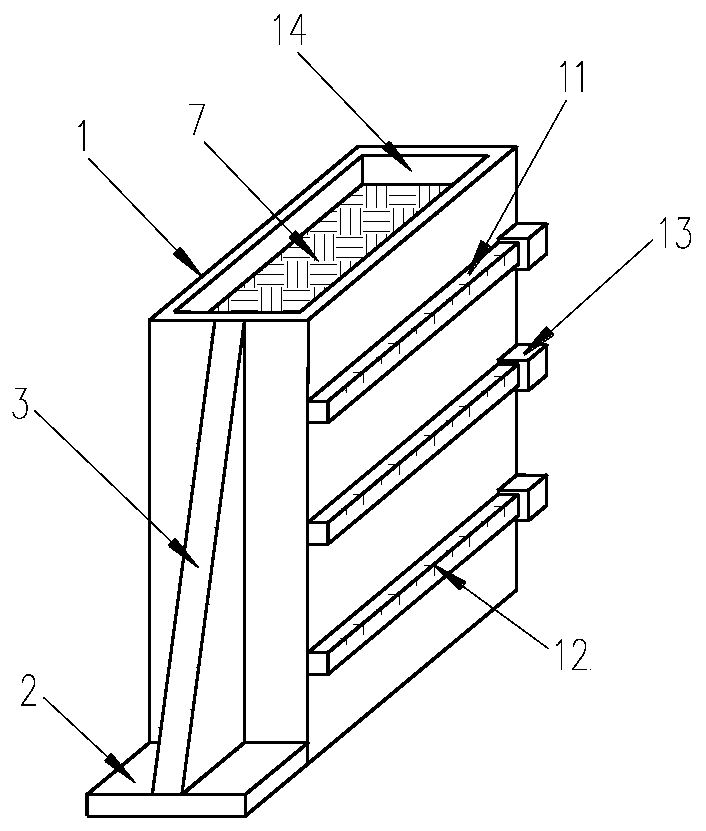

[0040] like Figure 1-6 As shown, the present invention provides a stepless pressure-fit retaining wall support system, including UHPFRC column 1, UHPFRC retaining plate 4, C-shaped lock 5, fastening bolt 6 and planting soil 7; wherein UHPFRC column 1 is provided with UHPFRC toe plate 2, UHPFRC rib 3, sliding beam 11, pier block 13, and embedded groove 14; Set on both sides of the UHPFRC column 1, three slide beams 11 are set on each side, and the surface of the slide beams 11 is provided with a scale bar 12 for monitoring the slippage; the pier 13 is set at the end of the slide beam 11 to prevent UHPFRC The soil retaining plate 4 slides out; the embedded groove 14 is arranged on the top of the UHPFRC column 1 for planting the planting soil 7; the UHPFRC soil retaining plate 4 is provided with a notch 41 that can be matched with the sliding beam 11, and the bolts are fastened 6 Fix the C-shaped lock 5 on the sliding beam 11 through the hole 5 on the C-shaped lock 5, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com