Combine harvester

A technology of combine harvester and linkage mechanism, which is applied in the direction of harvester, cutter, chassis of agricultural machinery, etc., can solve problems such as insufficient judgment of harvesting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

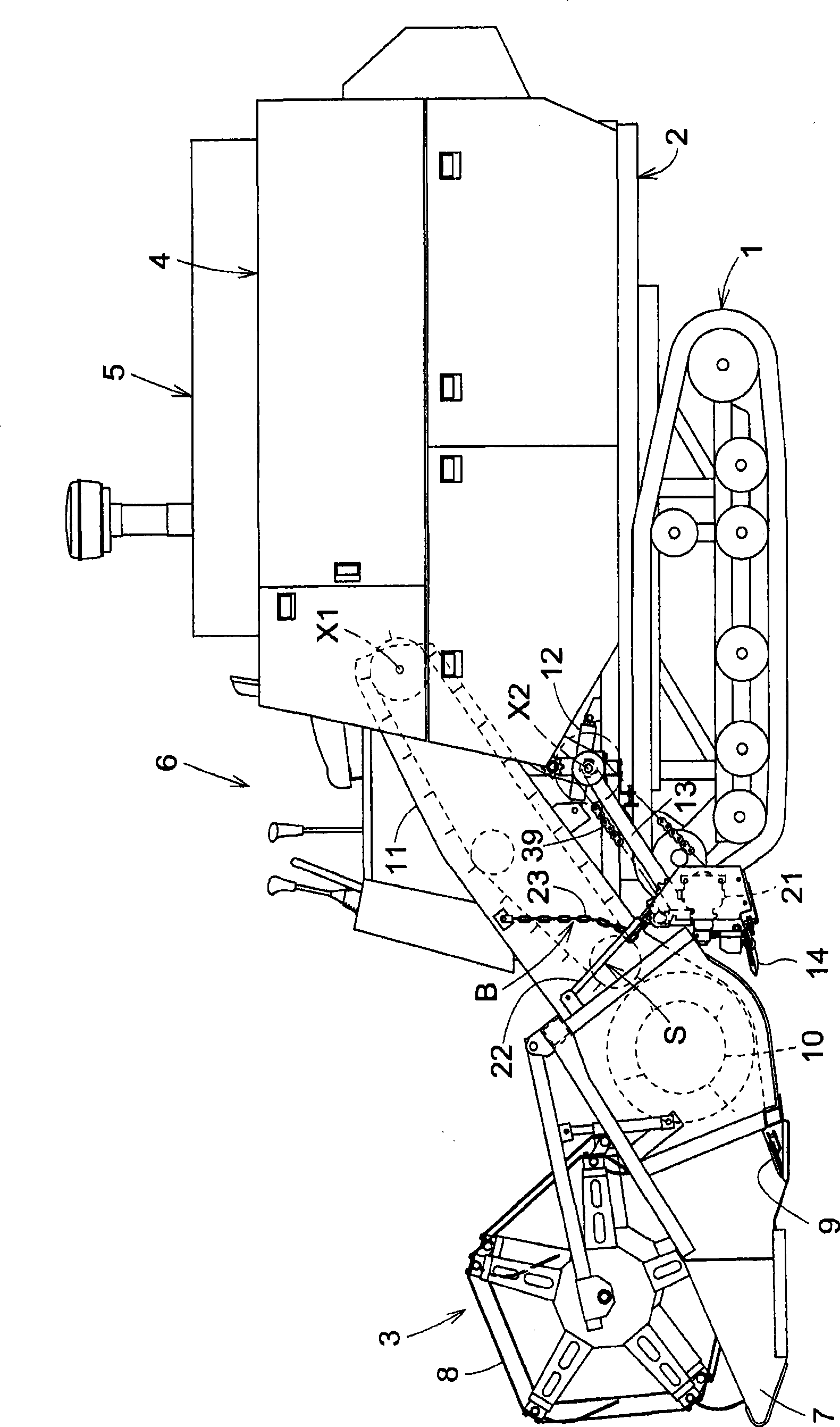

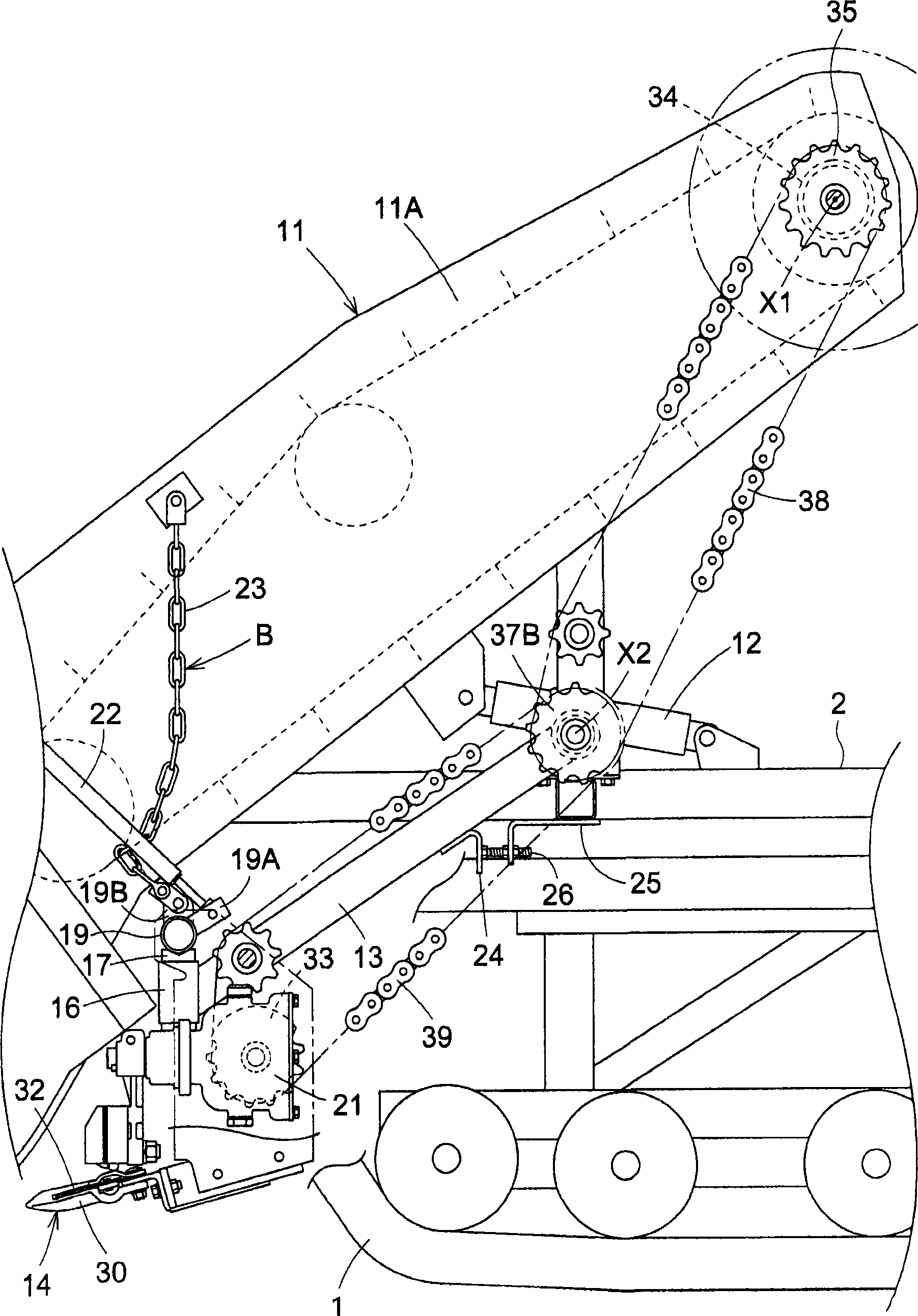

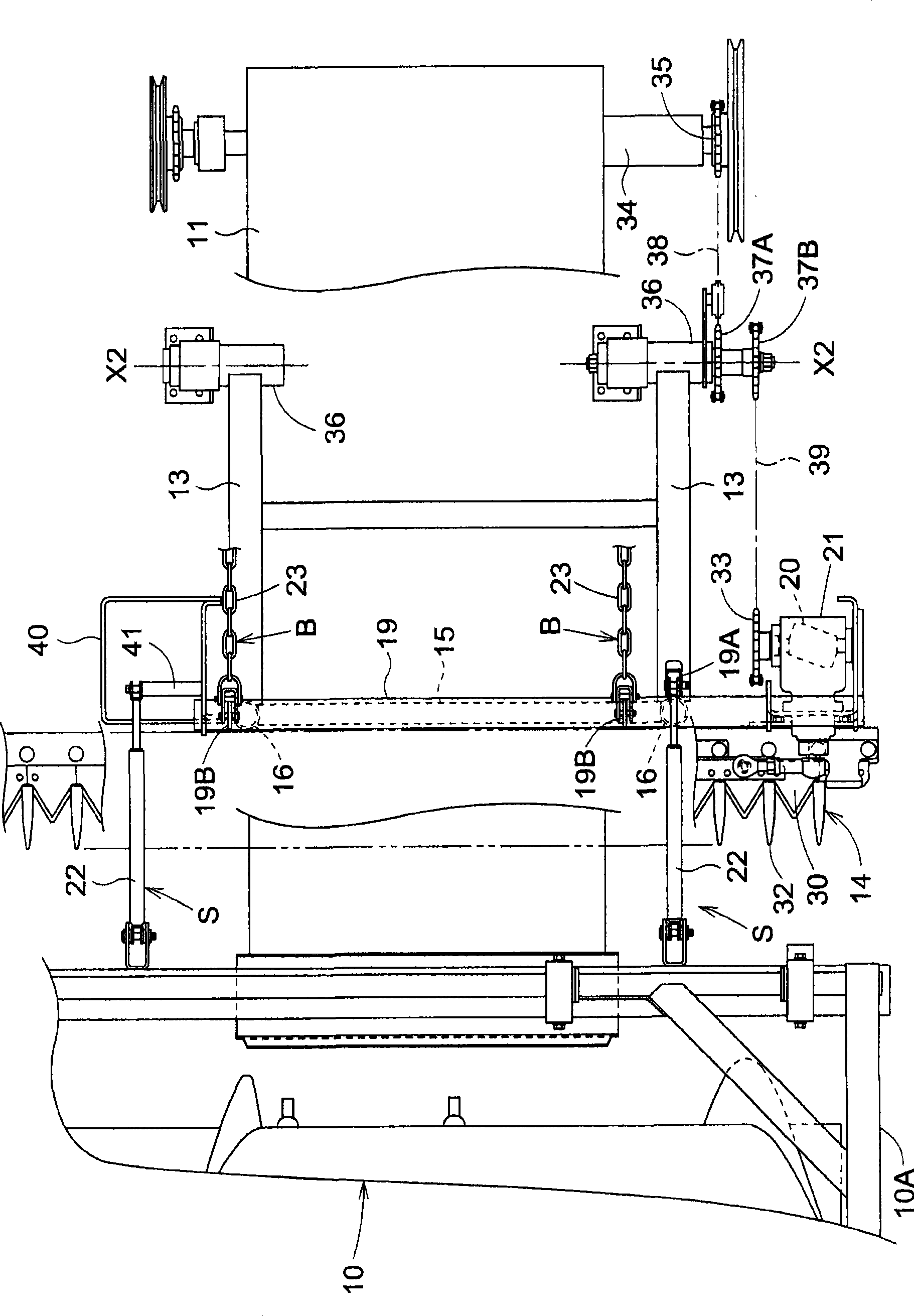

[0062] figure 1 The middle shows the overall side of the combine harvester, which is connected to the front part of the traveling body 2 traveling by driving the pair of left and right crawler-type traveling devices 1 so that it can swing up and down about the first axis X1 in the left-right direction. Next, the reaping conveying device 3 that reaps the reaping object straw and conveys it toward the rear is mounted on the traveling body 2 to carry out threshing treatment on the reaping object straw from the reaping conveying device 3 , and A threshing device 4 for sorting the treated products, a grain tank 5 for storing grains from the threshing device 4 , etc., and a boarding and driving part 6 are formed in front of the grain tank 5 of the traveling body 2 , constituted as a whole stalk input type in which rice or wheat is used as the stalk to be harvested.

[0063] Such as figure 1 and figure 2 As shown, the harvesting and conveying device 3 is constituted such that, ...

no. 2 Embodiment approach

[0089] Hereinafter, embodiments of the present invention will be described based on the description of the drawings.

[0090] exist Figure 7 The middle represents the overall side of the combine harvester. This combine is provided with the reaping conveyance system processing part A which reaps the stem to reap and conveys to the front part of the traveling body 101 provided with the right-and-left pair of crawler-type traveling apparatus 102, and conveys to the rear. The traveling body 101 is equipped with a threshing device 112 for inputting the whole harvested stalks supplied from the above-mentioned harvesting conveyance system processing part A and performing threshing and sorting processes, and storing grains from the threshing device 112. The grain bagging device 113 and the like for bagging are provided with a driver's seat 115 on the front part of the grain bagging device 13 on the traveling body 101, and constitute an overall threshing system that supplies the obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com