Worker roller abrasion forecasting method of cold continuous rolling device based on mechanism and operation condition

A technology for cold tandem rolling mills and work rolls, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of less research on mechanism models, no roll wear calculation model, and the lack of universality of wear model calculation methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

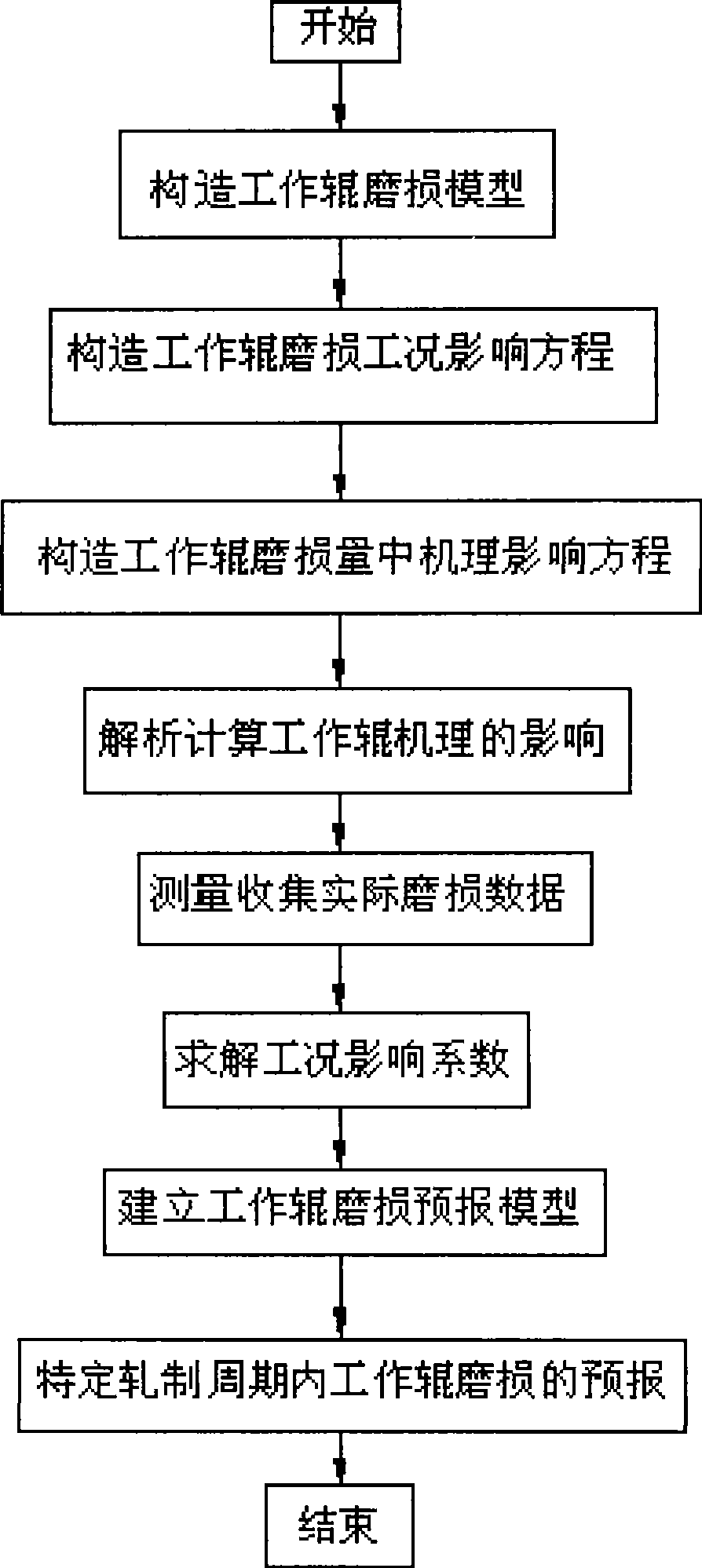

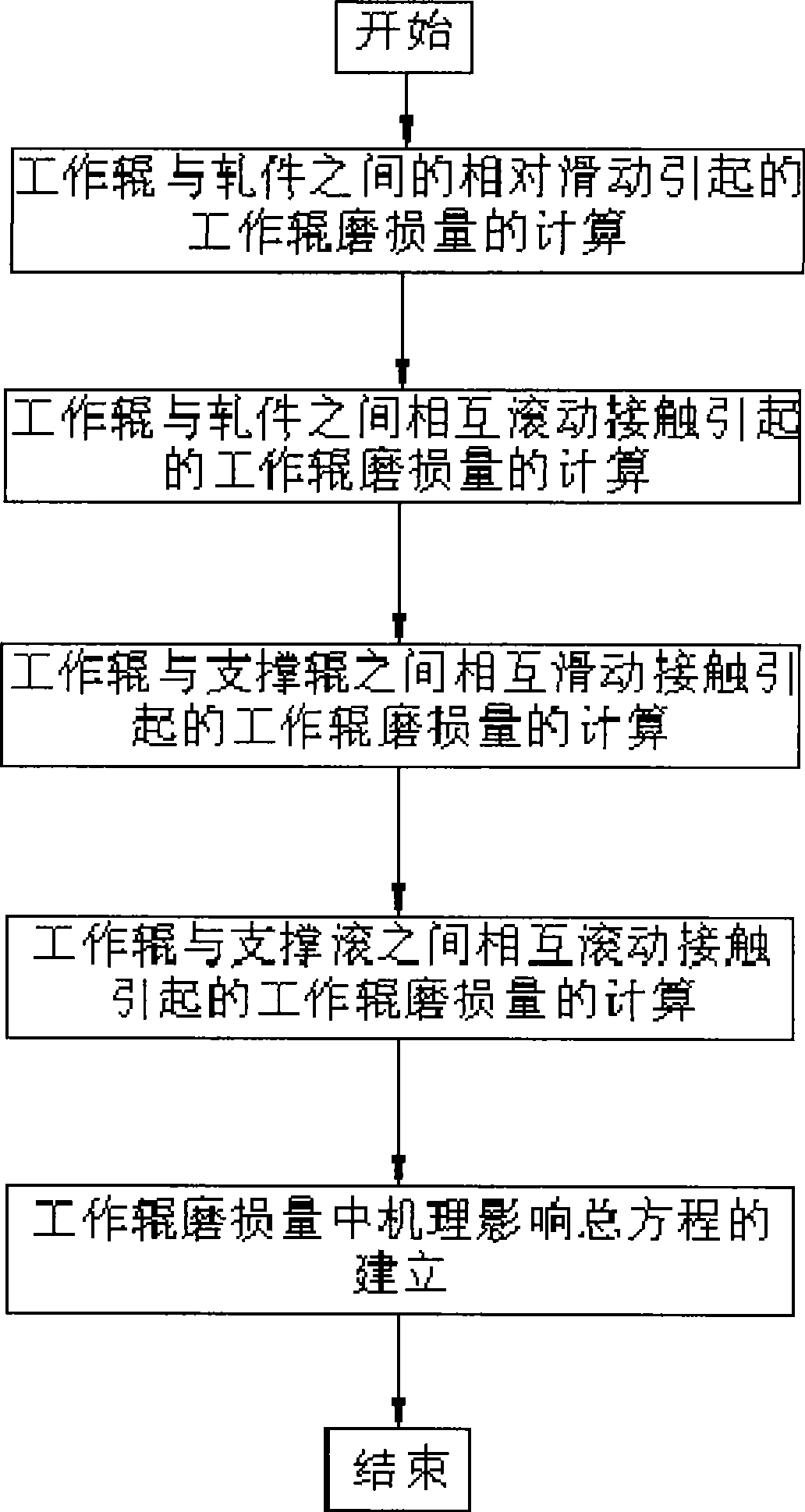

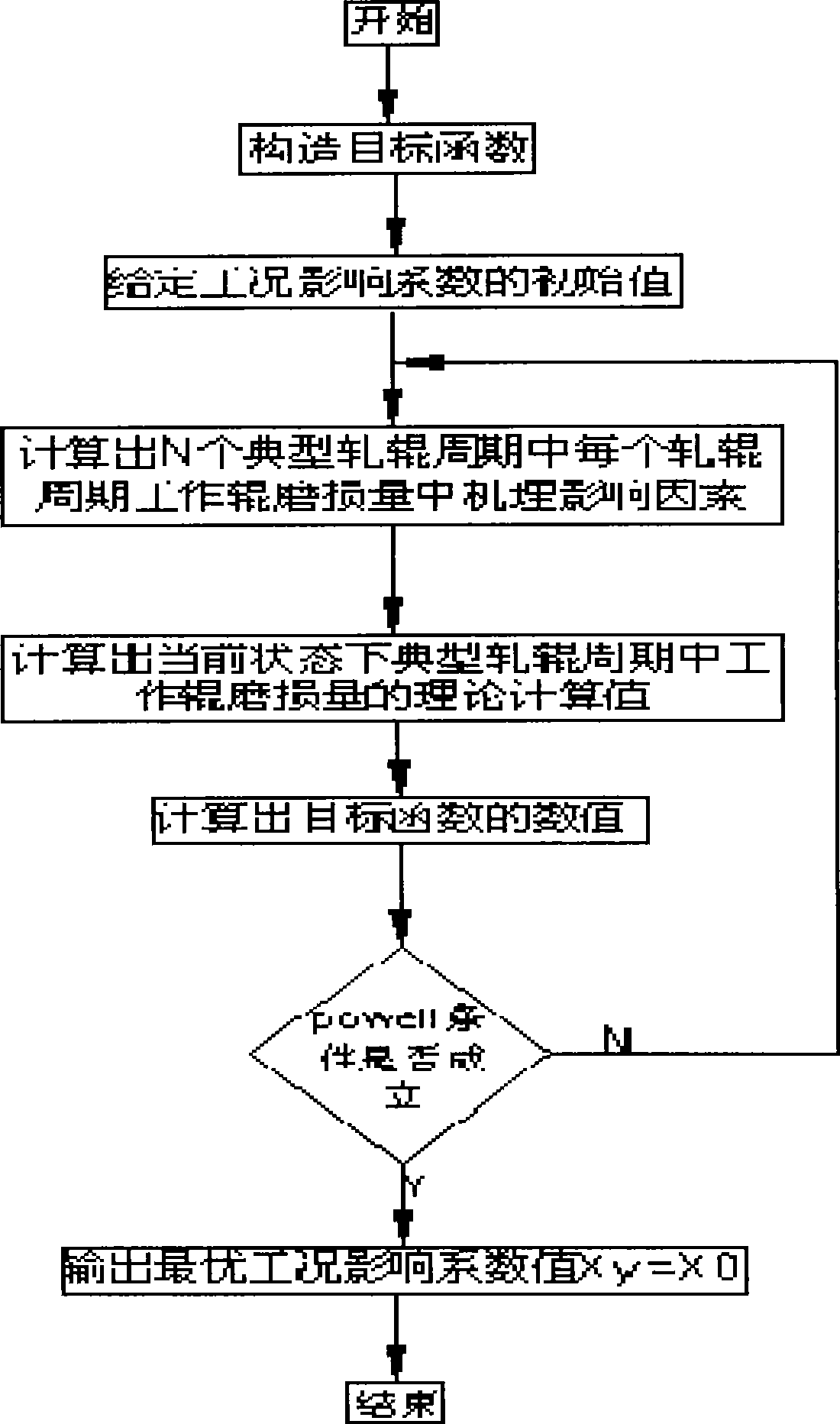

Method used

Image

Examples

Embodiment Construction

[0076] In order to actually verify the correctness of the roll wear method and the accuracy of parameter optimization in the technical solution described in this patent, taking a 1420 five-stand cold tandem rolling mill as an example, a two-rolling unit was taken to model the fifth stand simulation test. Combined with the production conditions of the rolling unit, the actual process parameters of the rolling unit and the parameters shown in Table 1 are substituted into the work roll wear model to predict the wear amount. The average relative error between the wear amount predicted by the model and the corresponding measured wear amount is less than 5.0%, and the maximum error is less than 15%, which meets the engineering prediction requirements for roll wear accuracy.

[0077] In order to further illustrate the implementation process of the patent of the present invention, the fifth stand of a 1420 five-stand cold rolling mill is taken as an example to briefly explain the mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com