Oil pump hot oil test desk and its use method

A test bench and oil pump technology, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve the problems of large test errors, large environmental differences, low test efficiency, etc., and achieve high efficiency, high automation and high efficiency. smart effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

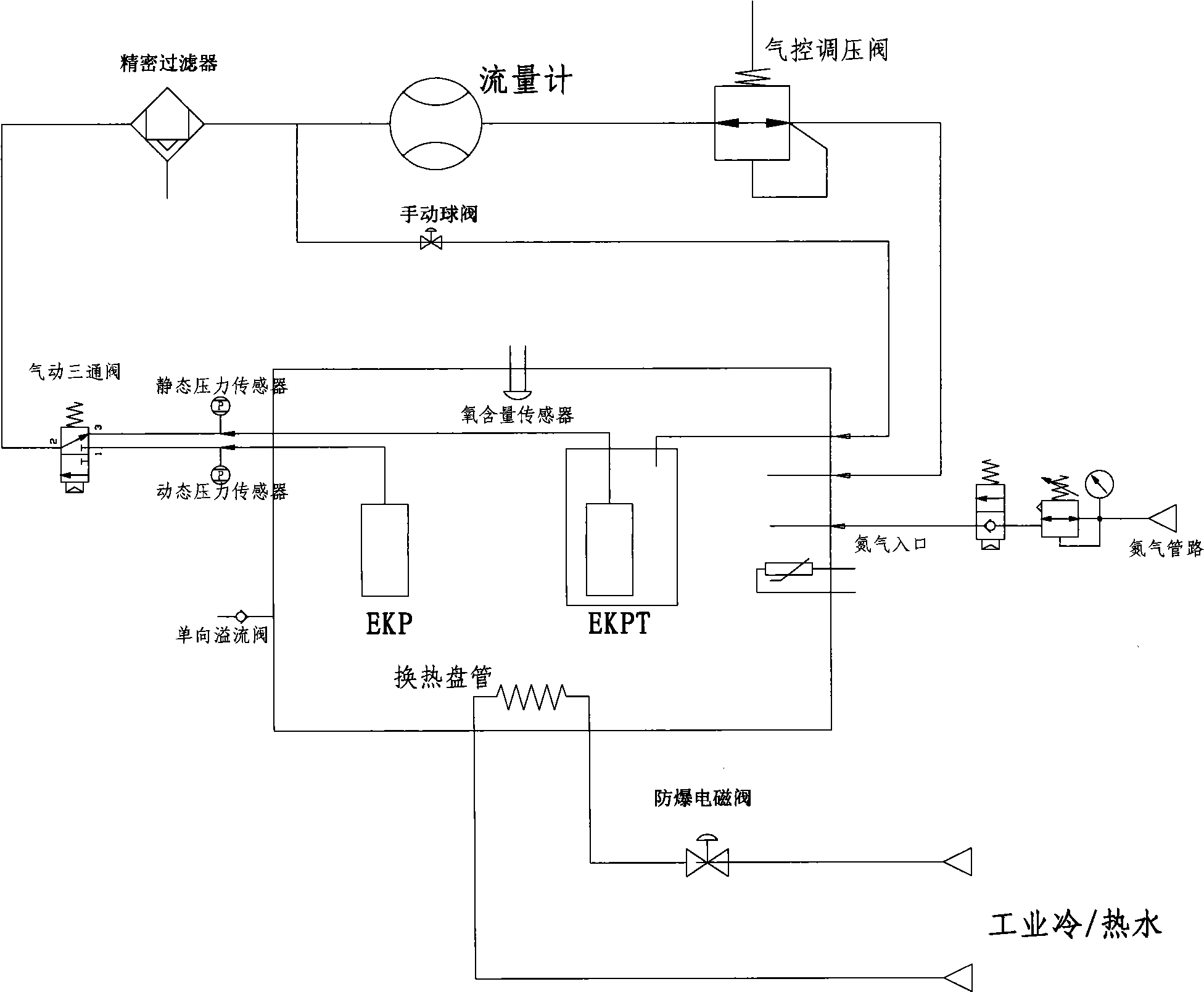

[0010] The oil pump performance test bench described in this embodiment is mainly used to test the oil delivery performance of the oil pump (EKP) and the oil pump support assembly (EKPT) under various temperature conditions, and other various performance indicators. In the specific embodiment, an oil pump is taken as an example for illustration, and the oil pump bracket assembly can also be used.

[0011] like figure 1 As shown, the structure of this embodiment includes an oil tank located on the test bench, the oil pump to be tested can be placed in the oil tank, and a sealing cover is installed on the oil tank, and the environment in the oil tank can be closed when the sealing cover is closed; the oil tank also provides Connect the fuel pipeline of the tested oil pump to simulate the working environment of the oil pump. When the fuel tank is in use, a certain amount of fuel is injected into it, and the fuel pump is connected with the fuel pipeline and placed in the fuel env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com