Diaphragm of diaphragm pump and molding technique thereof

A technology of diaphragm pumps and diaphragms, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of diaphragm fatigue fracture, diaphragm pump water leakage, diaphragm bending deformation, etc., and meet the requirements of bending deformation resistance and resistance Compressive strength, meeting sealing performance requirements, high flexibility and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

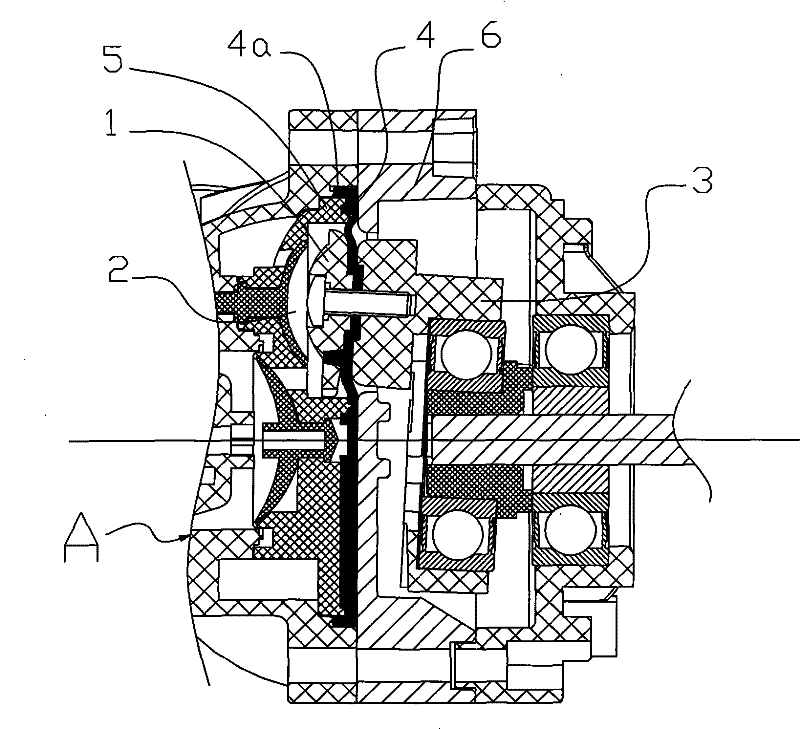

Embodiment 1

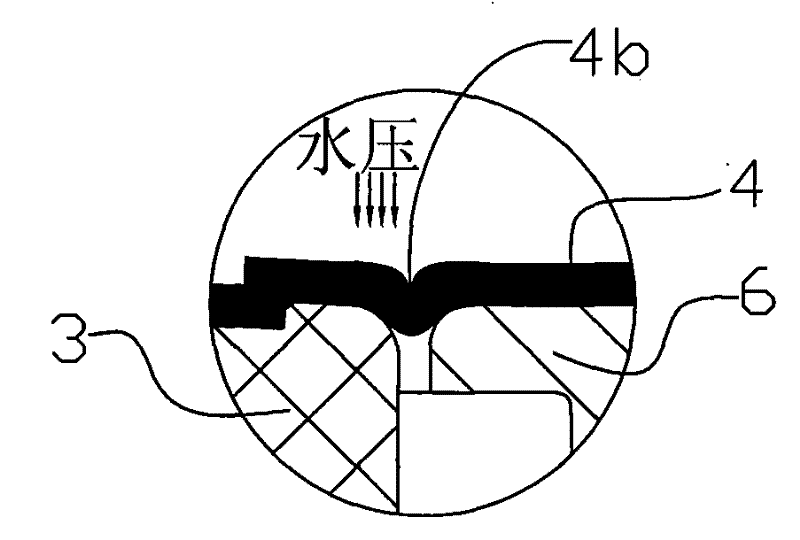

[0031] Embodiment 1 is: a soft modified PP layer or a soft modified PE layer or a soft modified PVC layer or a rubber layer constitutes the first layer of diaphragm 7, and a hard modified PP layer or a hard modified PE layer or a hard modified PVC layer Or the hard-modified PA layer constitutes the second membrane 8, and the first membrane 7 and the second membrane 8 are tightly matched to form an integral body, and have matching contact surfaces. The second layer of diaphragm 8 is closely attached to the first layer of diaphragm 7, so that the two are assembled as an integral structure, and can be coordinated when used, and have both soft and hard characteristics. There are three sunken platforms 8b on the front E of the diaphragm 8 of the second layer, and three bosses 7d on the back D of the first diaphragm 7, and the three bosses 7d of the first diaphragm 7 fit on the second layer. In the three recessed platforms 8b of the diaphragm 8. The outer peripheral surface of the ...

Embodiment 2

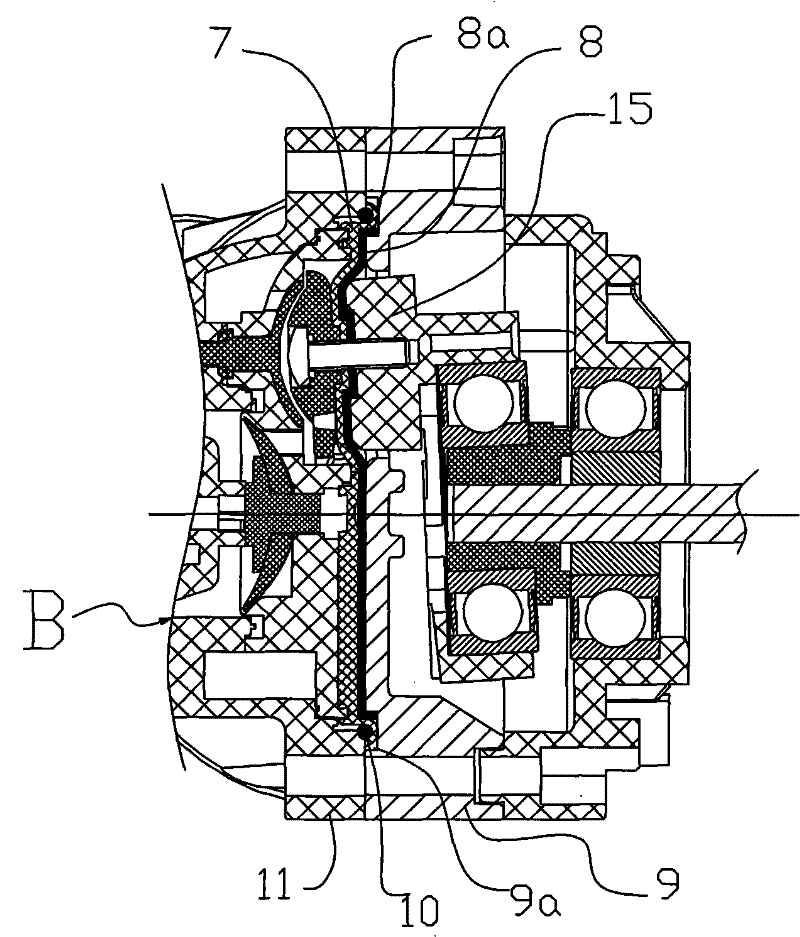

[0036] Embodiment 2 is: a soft modified PP layer or a soft modified PE layer or a soft modified PVC layer or a rubber layer constitutes the first layer of diaphragm 7, and a hard modified PP layer or a hard modified PE layer or a hard modified PVC layer Or the hard modified PA layer constitutes the second layer of diaphragm 8, and the first layer of diaphragm 7 and the second layer of diaphragm 8 are made into one through secondary injection molding, and have a fused contact surface. The second layer of diaphragm 8 is fused with the first layer of diaphragm 7, so that the two form an integrated structure, which can be coordinated during use and has both soft and hard characteristics.

[0037] The outer peripheral surface of the first layer of diaphragm 7 is formed with a first peripheral edge 7a and a second peripheral flange 7b extending upwards, and the first peripheral flange 7a and the second peripheral flange 7b form a concave circumference for snapping into the sealing me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap