Boiler/drying oven hearth flameout automatic detection method and automatic protective system

An automatic protection and automatic detection technology, applied in the direction of control/regulation system, combustion method, general control system, etc., can solve the problems of time delay, loss of monitoring meaning, time lag of accidents, etc., and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

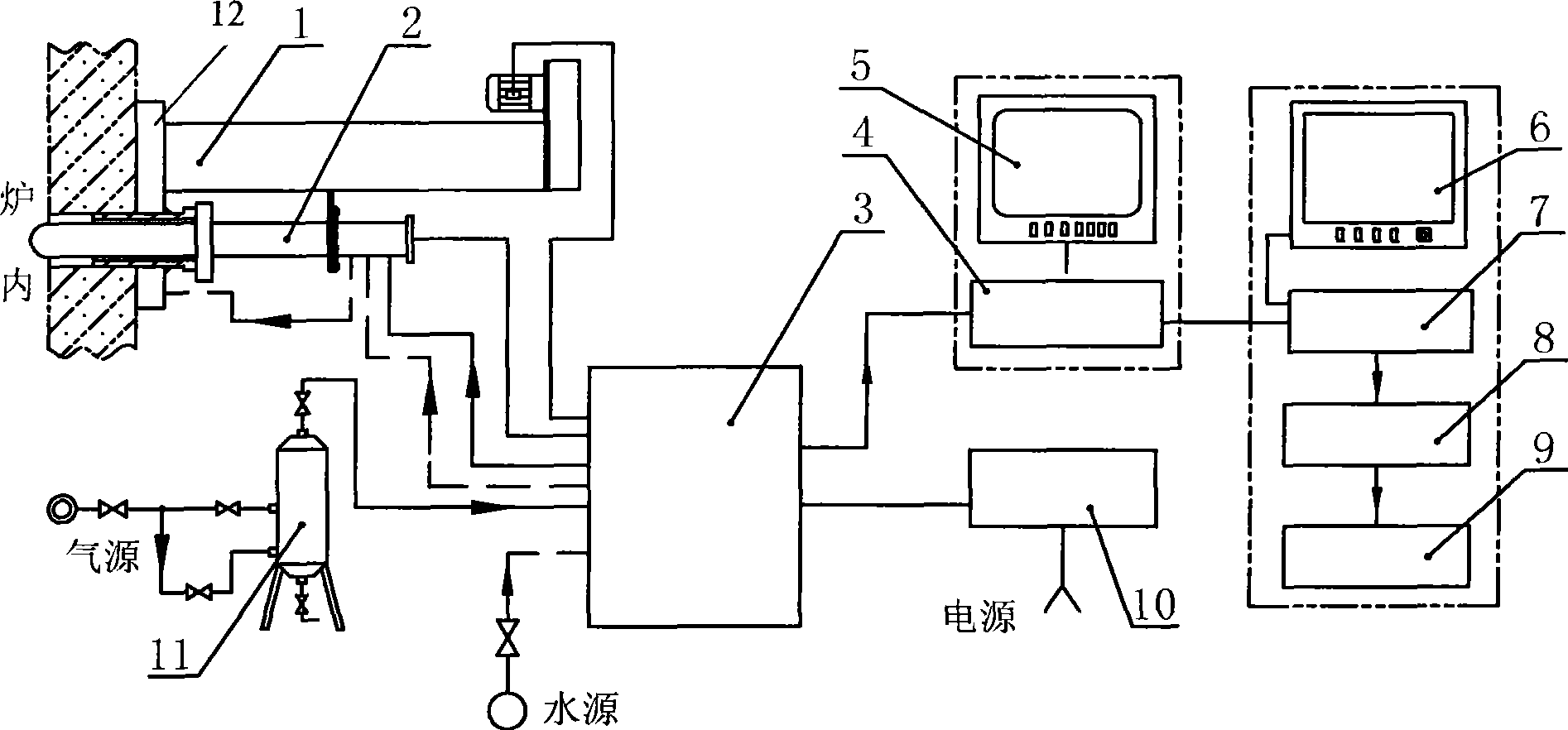

[0035] The boiler / drying furnace furnace flame-out automatic detection method and automatic protection system of the present invention will be described in detail below in conjunction with the accompanying drawings.

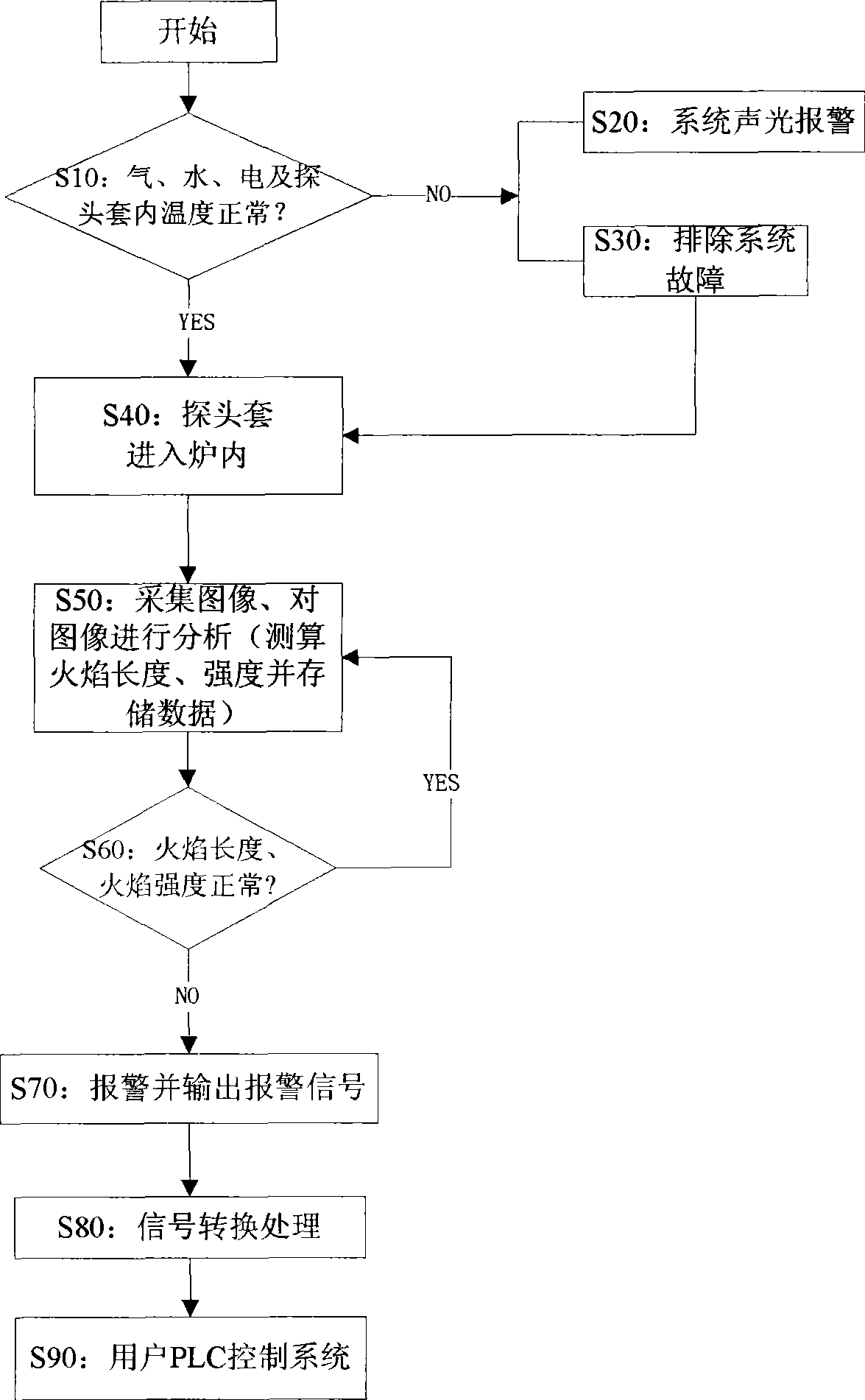

[0036] Such as figure 1 Shown, boiler / drying furnace hearth flame flameout automatic detection method of the present invention comprises the following steps:

[0037] 1) Determine whether the cooling water, cooling air and system power used to cool the probe cover are normal, if normal, perform step 3), if not normal, perform step 2) (S10 stage);

[0038] 2) The system sends out an alarm signal (S20 stage), and at the same time manually eliminates the system failure (S30 stage);

[0039] 3) The probe cover enters the furnace cavity (S40 stage);

[0040] 4) Collect images through the camera probe in the probe cover, and analyze the collected images (S50 stage);

[0041] 5) Judging whether the length and intensity of the flame are normal according to the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com