Test methods for acquiring thick wall cylinder sample ring fracture

A test method and cylinder technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of unclear production mechanism, and achieve the effect of wide practicability and good simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

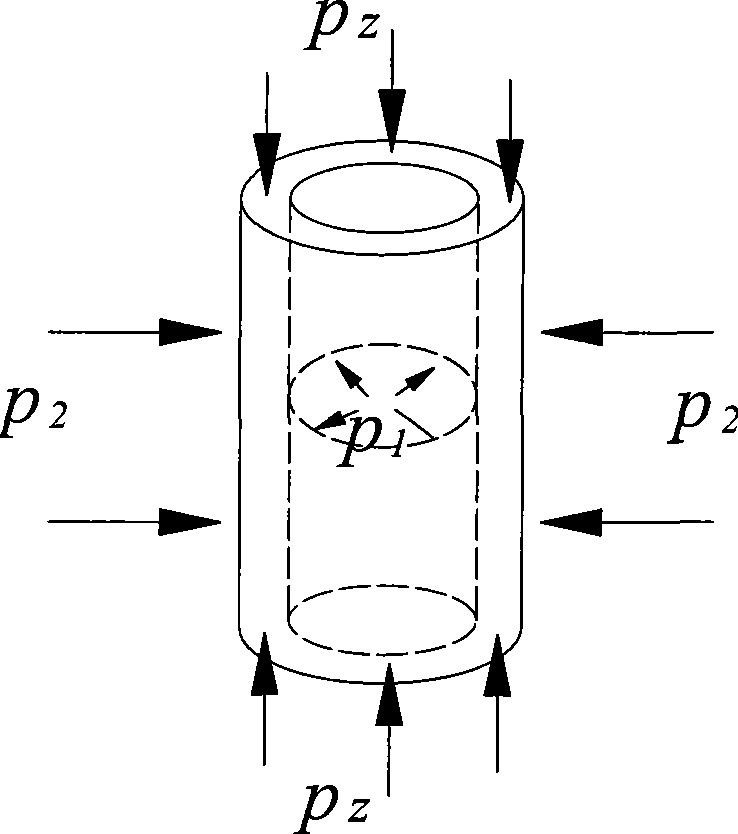

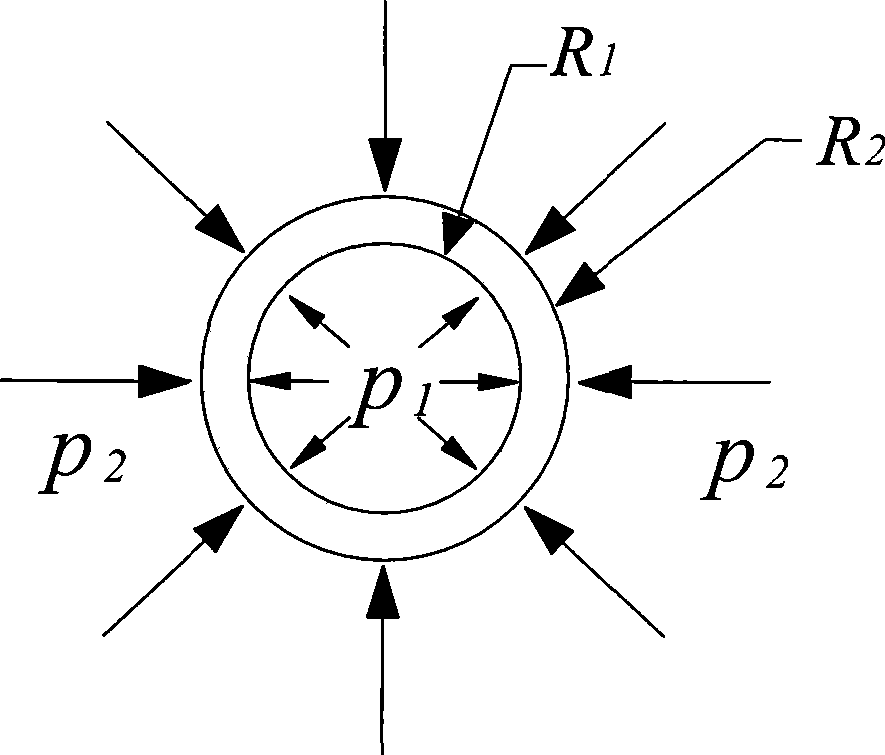

[0018] The test method for obtaining the annular fracture of the thick-walled cylinder sample of the present invention: first adopt a rock drilling rig with a concentric drill bit to sample the test rock mass object, and make the rock sample into a cylinder wall thickness and its inner hole radius R 1 For thick-walled cylindrical samples whose ratio is greater than 0.2, use a servo triaxial pressure testing machine including axial pressure system, confining pressure system and internal pressure system to test the thick-walled cylindrical samples. The test method is as follows:

[0019] Approach A: Place the thick-walled cylindrical sample in the airtight loading chamber of the servo triaxial pressure testing machine, and first apply 10MPa axial pressure p z , so that the sample is in close contact with the upper and lower rigid loading ends, and then oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com