Jellify resistance power cable

A power cable and freezing technology, which is applied in the field of power cables, can solve the problems that power cables cannot resist severe freezing disasters, and achieve a good anti-freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structural details of the anti-freezing power cable of the present invention will be described below in conjunction with the drawings and principle experiments.

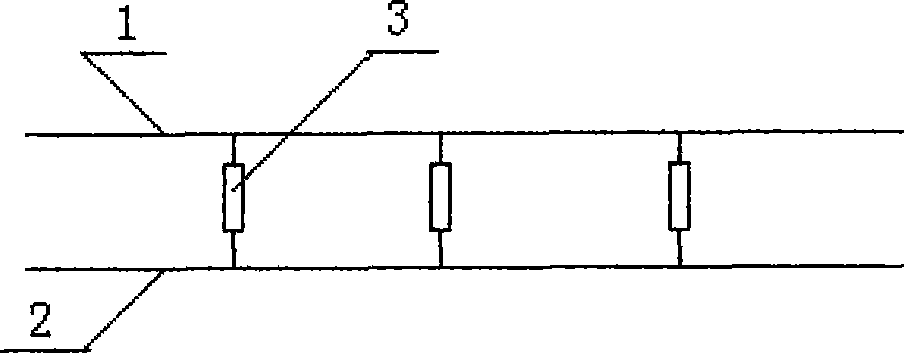

[0018] Such as figure 1 As shown, the running sub-cable (1), the auxiliary sub-cable (2) and the electric heater (3) are electrically connected by contact or connection, when the voltages in the running sub-cable (1) and the auxiliary sub-cable (2) are not equal , that is, a current flows through the electric heating body (3), and the electric heating body (3) can generate heat.

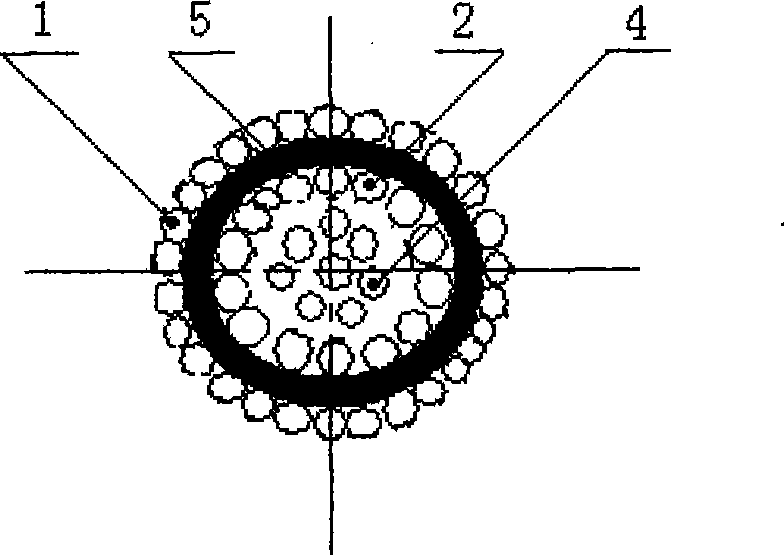

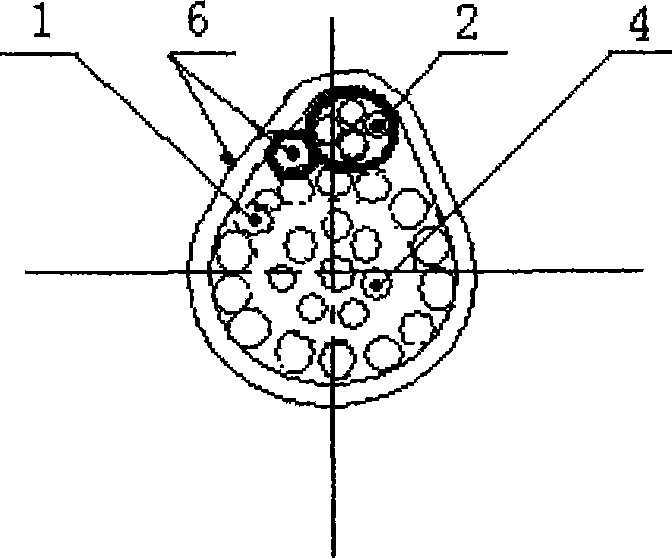

[0019] When the electric heating body (3) is an annular electric heating ring (5), such as figure 2 , Figure 5 As shown, the auxiliary sub-cable (2) is set outside the steel core (4). Outside the electric heating ring (5), there is an insulating ring (7) between every two electric heating rings (5) to separate. Electric heating ring (5) is made of PTC electric heating material.

[0020] The voltage environment during the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com