Switch constant-current source circuit without feedback on load end

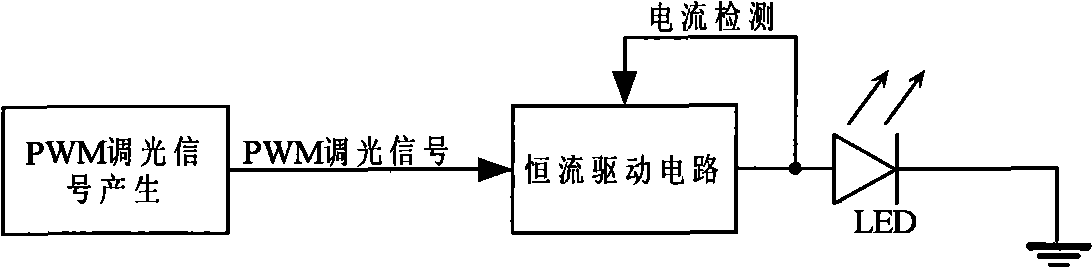

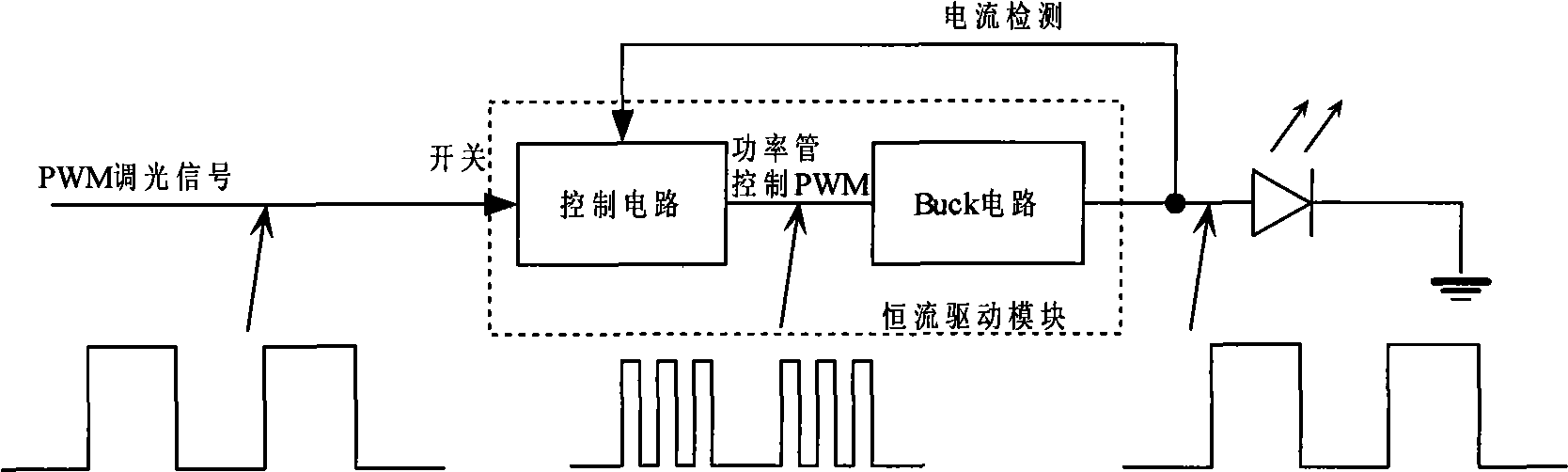

A technology of constant current source and circuit, applied in the direction of lamp circuit layout, light source, electric light source, etc., can solve the problems of different brightness, constant current failure, sensitive instruments and equipment, etc., to solve high-frequency flicker and EMI problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

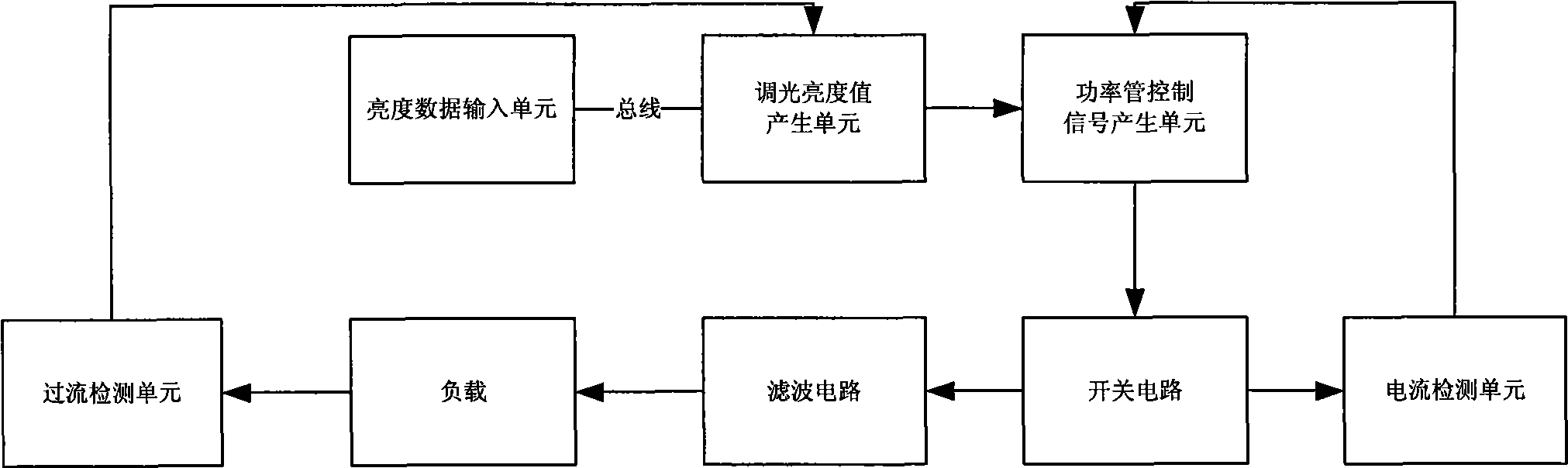

[0016] see image 3 The switch constant current source circuit without feedback at the load end of the present invention at least includes: a brightness data input unit, an overcurrent detection unit, a bus, a dimming brightness value generation unit, a power tube control signal generation unit, a switch circuit, a filter circuit, and current detection unit.

[0017] The brightness data input unit has a bus interface for inputting brightness data, wherein the brightness data can be DMX data conforming to the DMX512 protocol.

[0018] The over-current detection unit is connected to a load for detecting whether the load current reaches an over-current value, which may include an optocoupler connected to the load, and the load may be an LED or the like.

[0019] The bus can be an RS485 bus.

[0020] The dimming brightness value generation unit has a bus interface, is connected to the overcurrent detection unit, and is connected to the brightness data input unit through the bus,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com