Method of forming inner liner for tire and process for producing pneumatic tire

一种成型方法、制造方法的技术,应用在充气轮胎、没有单独的充气垫、轮胎零部件等方向,能够解决空气积存等问题,达到避免空气积存的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

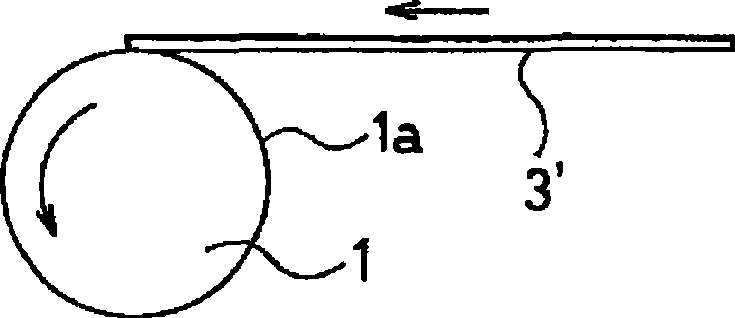

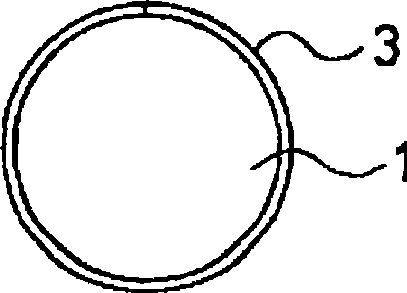

[0076] A cylindrical inner rubber layer is formed by winding a sheet-shaped unvulcanized rubber layer with a thickness of 0.3 mm on a forming drum, and a sheet-shaped film layer with a thickness of 0.2 mm is wound on the outer peripheral side of the inner rubber layer to form a cylindrical shape. film layer, and then wound a sheet-shaped unvulcanized rubber layer with a thickness of 0.5mm on the outer peripheral side of the cylindrical film layer to form a cylindrical outer rubber layer and form an inner lining layer, and 50 pieces were produced Figure 10 A test tire of the structure shown (Example 1).

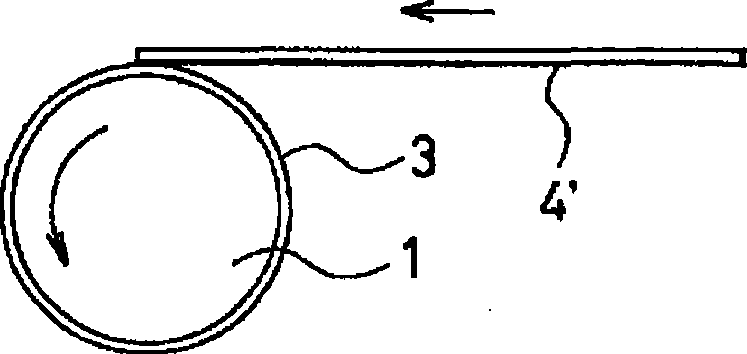

[0077] Also, a cylindrical inner rubber layer is formed by winding a sheet-shaped unvulcanized rubber layer with a thickness of 0.5 mm on a forming drum, and a sheet-shaped film layer with a thickness of 0.2 mm is wound on the outer peripheral side of the inner rubber layer to form Cylindrical film layer, and then spirally wound a strip-shaped rubber layer (width W215mm, rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com