Spouted pouch

A technology with a spout and a spout, which is applied to the field of bags with a spout, can solve the problems of automatic closure and other problems that have not been proposed, and achieve the effect of preventing rupture and slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

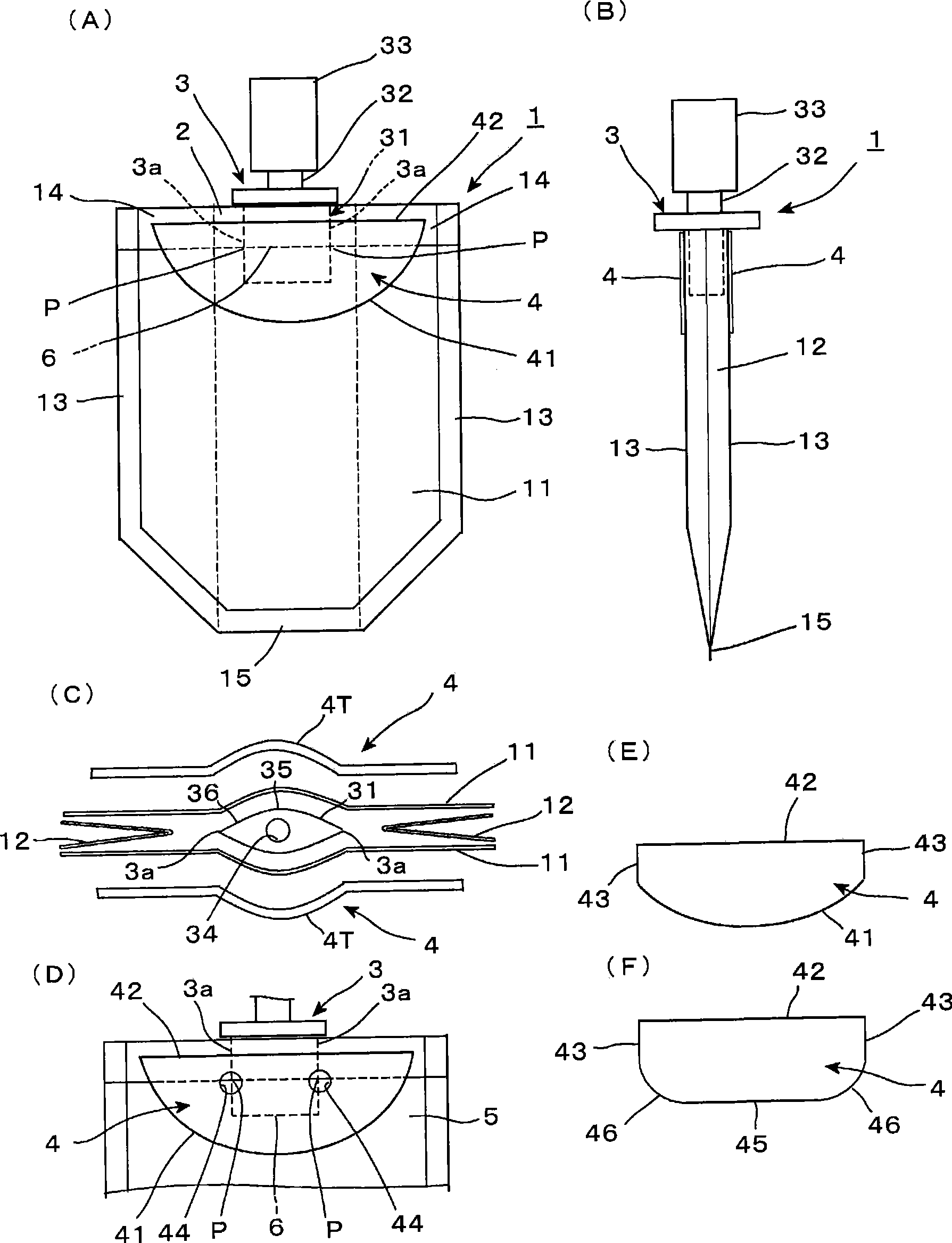

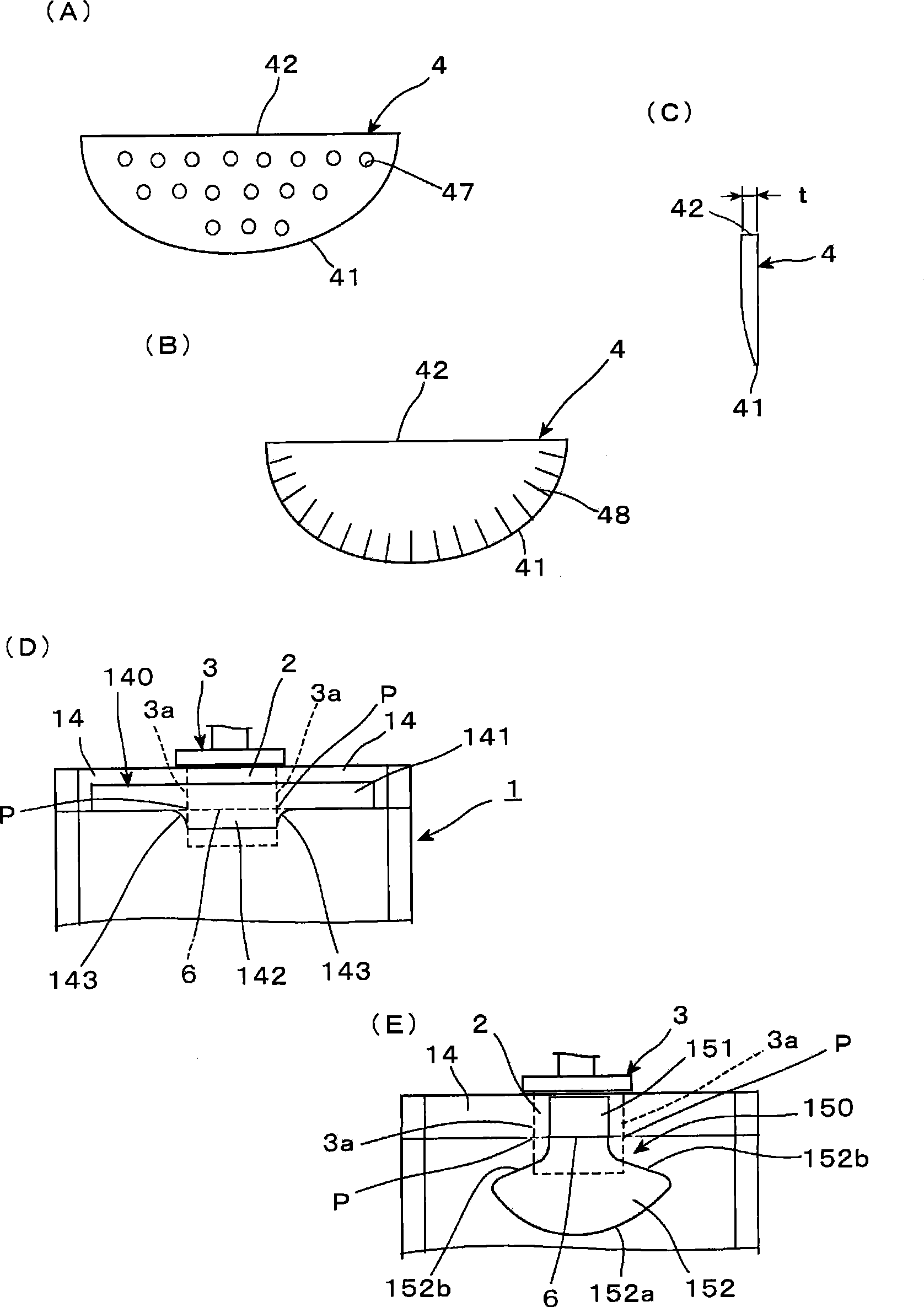

[0063] figure 1 A spouted bag according to a first embodiment of the invention is shown.

[0064] The bag with a spout has a bag shape made by laminating flexible films, and includes: a bag body 1 in which end portions of the films forming a seam are thermally fused and sealed; and a spout 3 provided on The film end portions of the bag body 1 are thermally fused between and together with these film end portions. Further, the stress dispersing sheet 4 is provided as a stress dispersing member and bonded to the outer surface of the bag body 1 so as to partially cover the spout sealing portion 2 and the deformable film portion 5 of the spout 3 in the following manner: The stress dispersing sheet 4 is made to straddle the boundary portion 6 between the spout sealing portion 2 as the thermal fusion portion and the deformable film portion 5 facing the inner space of the bag body 1 .

[0065] The bag body 1 in the example shown is of the newspaper bag (gazette bag) type, and as ...

no. 2 example

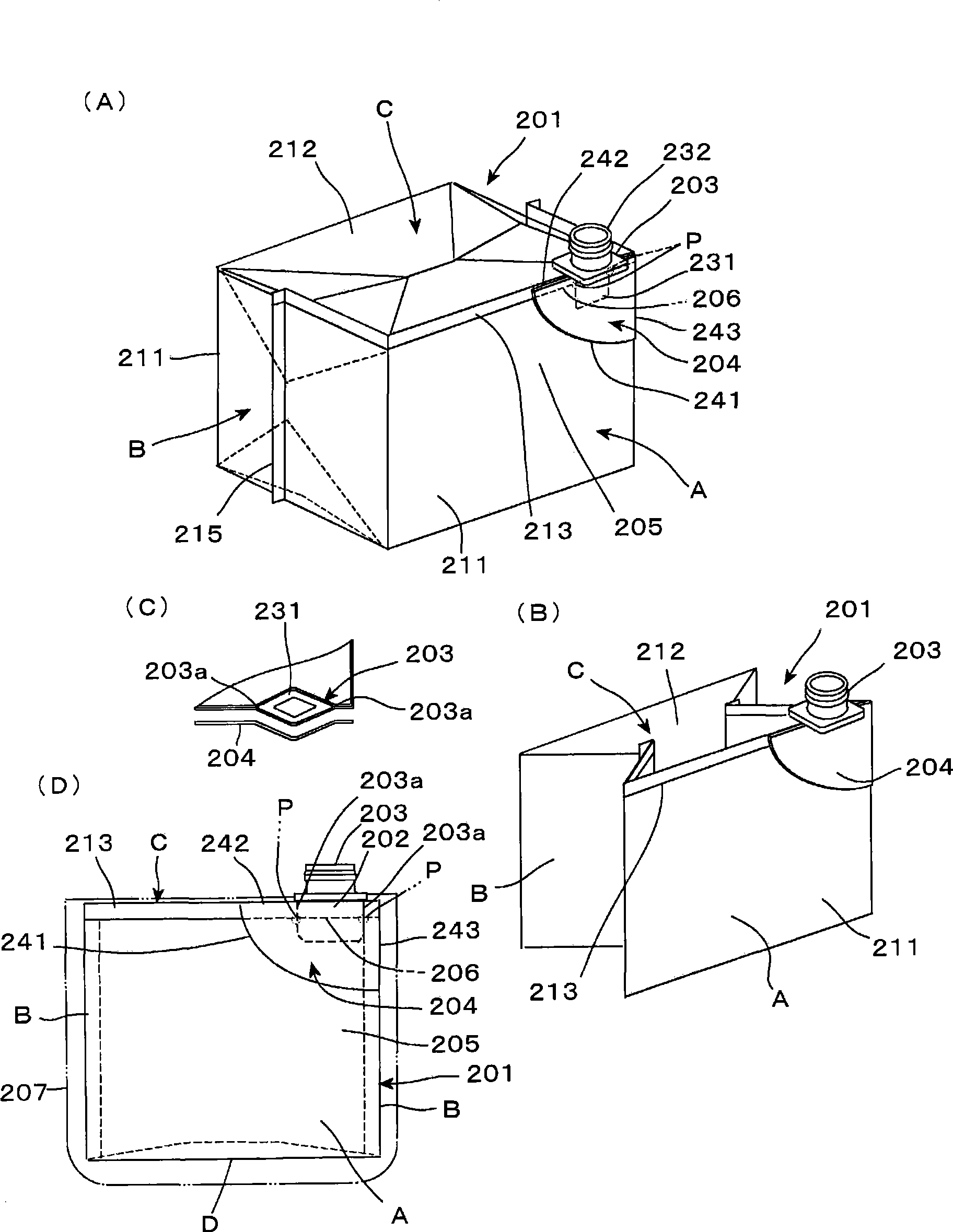

[0093] image 3 A spouted bag according to a second embodiment of the invention is shown.

[0094] The spouted bag is accommodated in a packaging container having high rigidity and is fixed to the packaging container 207 via the spout 203 . In this structure, the capacity of the bag in the state of being accommodated in the packaging container 207 is reduced.

[0095] The bag with a spout has a bag body constituted by laminating flexible films, and the bag body is provided with a bag body 201 and a spout 203, wherein the bag body 201 is formed by thermally fusing the ends of the films and then sealing them to form a connection The spout 203 is inserted between the film end portions of the bag body 201 and is thermally fused and sealed together with the film end portions.

[0096] The pouch body 201 is manufactured by bending a flat film material into a pair of front and rear flat surface film portions 211, 211 and a pair of side surface film portions 212, 212 folded between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com