Frock and device for rapid installation of hinge

An installation method and tooling technology, applied in the field of hinge quick installation tooling, can solve the problems of labor-intensive, time-consuming, low installation efficiency, etc., and achieve the effects of reducing installation cost, novel structure design, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

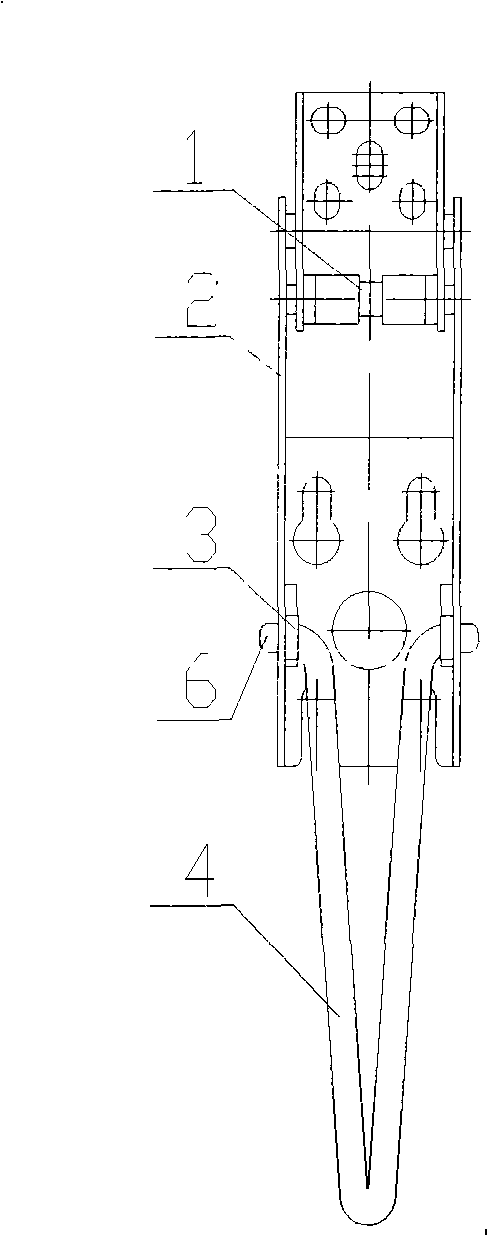

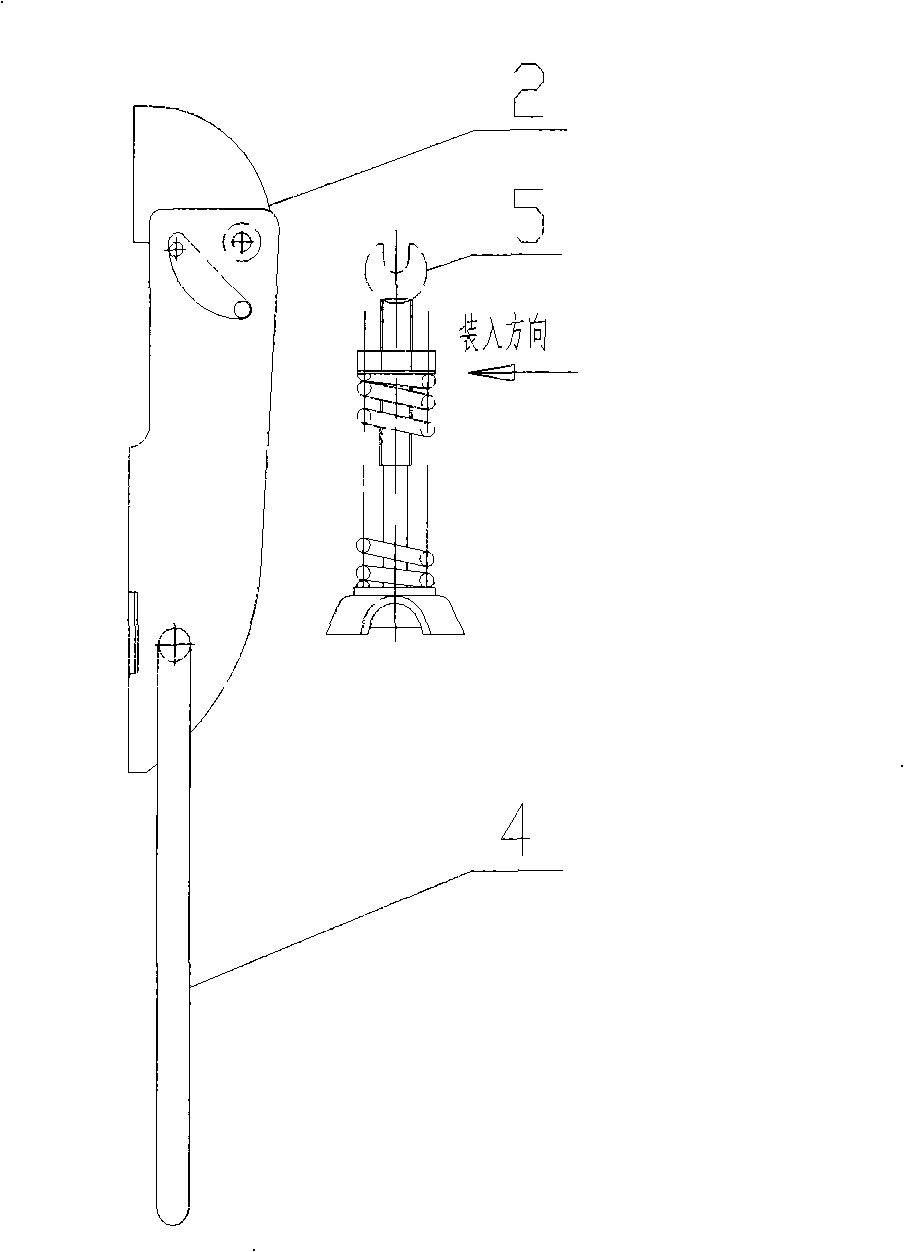

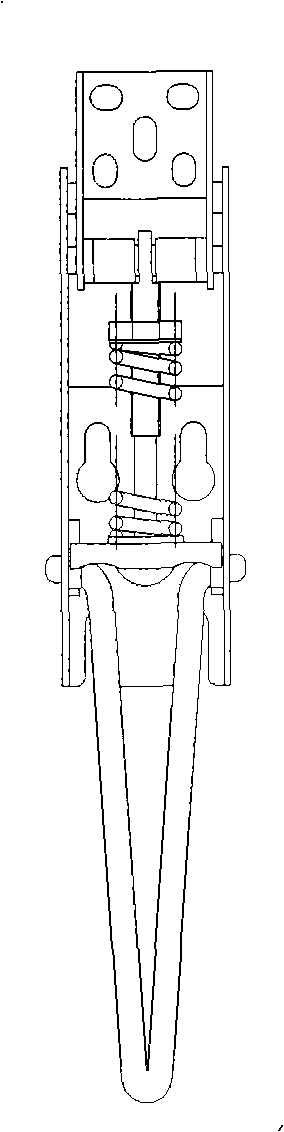

[0013] Example 1: refer to the attached Figures 1 to 5 . A hinge quick installation tooling, the tooling 4 has a V-shaped structure and the two ends of the V-shaped are clamped shaft heads 6, and the V-shaped tooling is made by bending elastic steel bars. narrative.

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, a method for quick installation of a hinge includes a hinge assembly 2 and a spring assembly 5. Both the hinge assembly 2 and the spring assembly 5 are manufactured in the prior art and are used for the installation of freezers. The relative shaft hole is opened in the relative inner side of the lower inner side of the hinge assembly 2 shell of the spring assembly 5 boss 3. When installing the spring assembly 5, the two clamping shaft heads 6 of the V-shaped tooling 4 are inserted into the hinge assembly 2 shell. In the lower shaft hole, see appendix figure 1 and 2 , and then connect the upper slot of the spring assembly 5 with the shaft at the upper part of the hinge assembly 2, and the lower end is placed between the two rods of the V-shaped tooling 4, see attached image 3 , at this time, turn the V-shaped tooling 4 up, see attached Figure 4 , the groove compression springs located on both sides of the lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com