Floor support plate

A technology for floor decks and floor plates, applied to floors, building components, buildings, etc., can solve the problems of increasing the weight of floor decks, increasing profiled steel plates, increasing construction costs, etc., to save steel, increase load capacity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

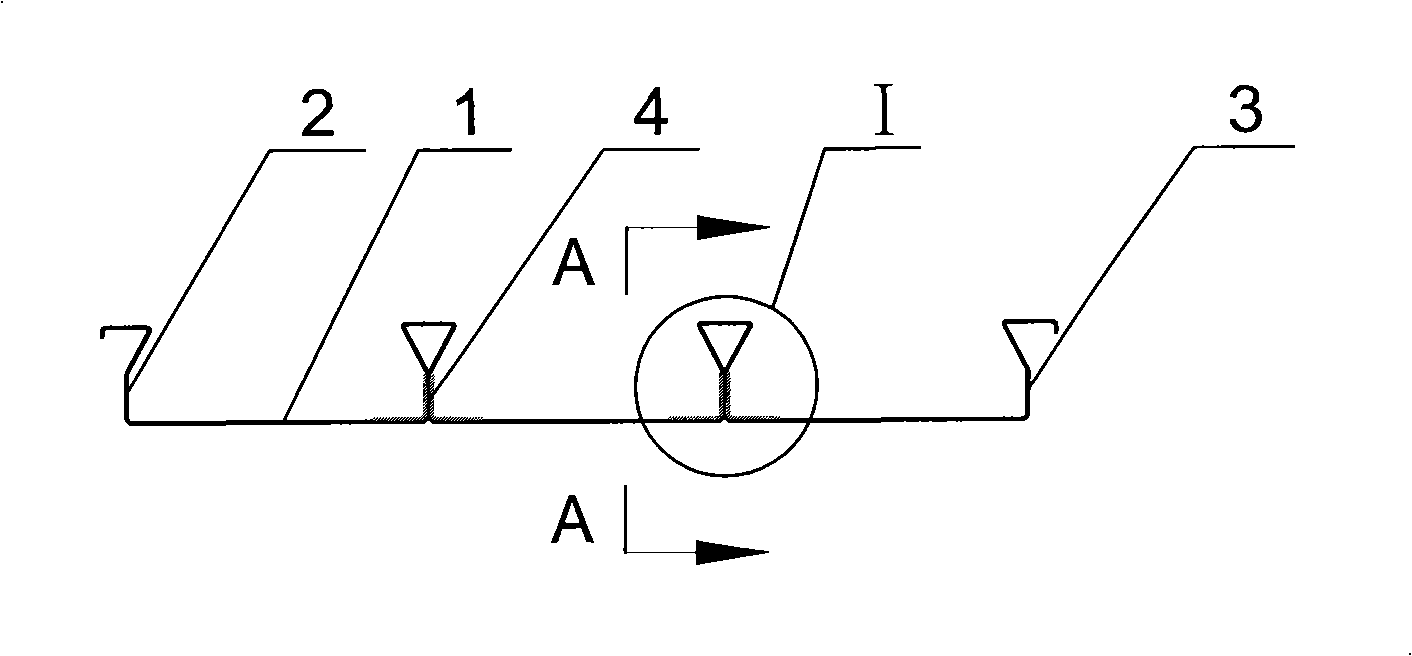

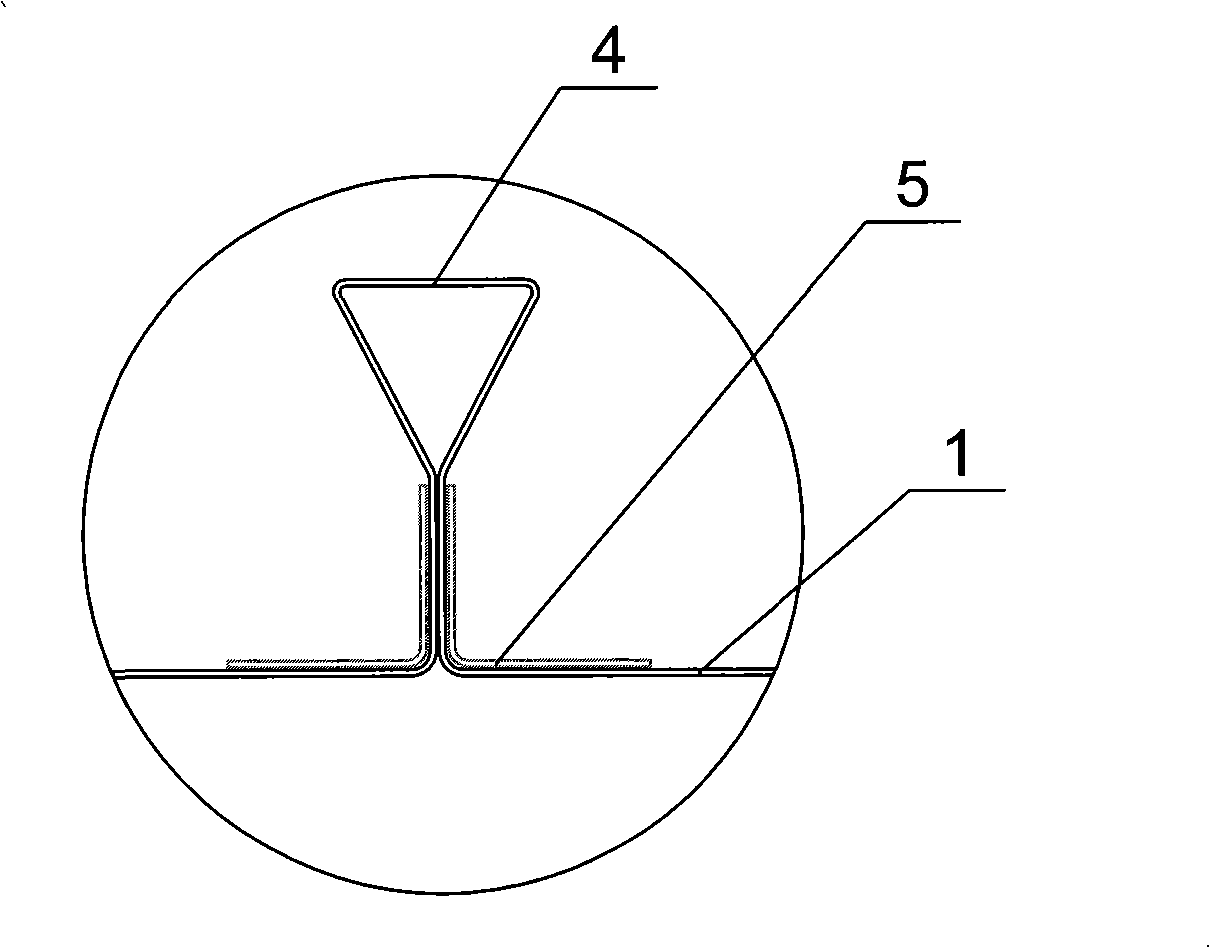

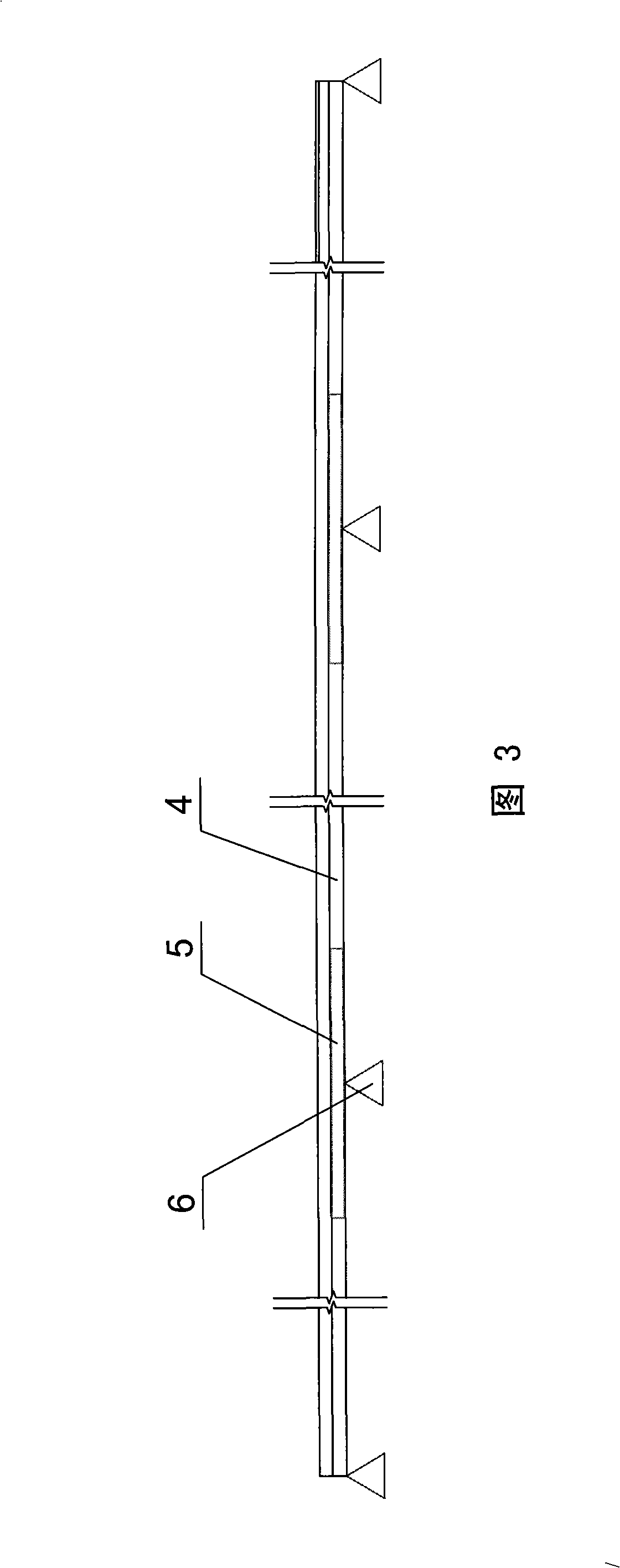

[0012] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a base plate 1, I buckle sides 2 and II buckle sides 3 on both sides, ribs 4 arranged at intervals on the top of the bottom plate 1, the I buckle sides 2 and the II buckle The edge 3 is matched, and several metal reinforcements 5 are riveted on the two sides of each of the ribs 4. Of course, the connection form between the two sides of the ribs 4 and the metal reinforcements 5 can also be Using other connection methods such as welding, the metal reinforcement 5 is arranged at a position corresponding to the fulcrum 6 of the floor deck. The metal reinforcement 5 is in an "L" shape, and the two right-angled sides of the metal reinforcement 5 are respectively It is riveted and fixed with the side of the rib 4 and the bottom plate 1, the rib 4 is a closed rib, and the cross section of the wedge of the rib 4 can be triangular, circular or other polygonal shapes. Of course, the ribs 4 may also...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap