Heat exchanger and method for manufacturing same

A technology for heat exchangers and manufacturing methods, which is applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of heat exchanger performance degradation, fluid dispersion, and pressure loss increase, so as to improve heat Exchange performance, improve pressure resistance, improve the effect of bias current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

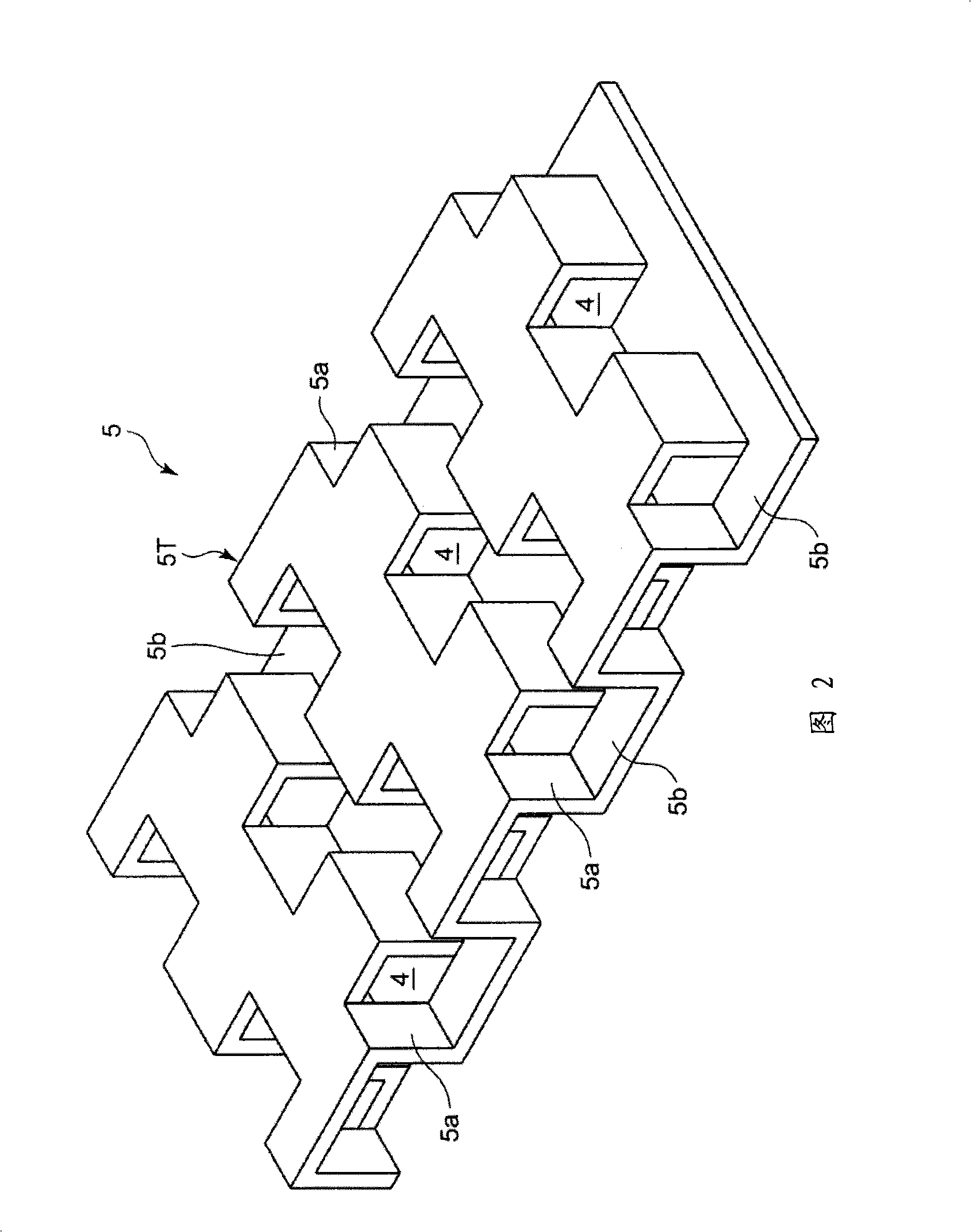

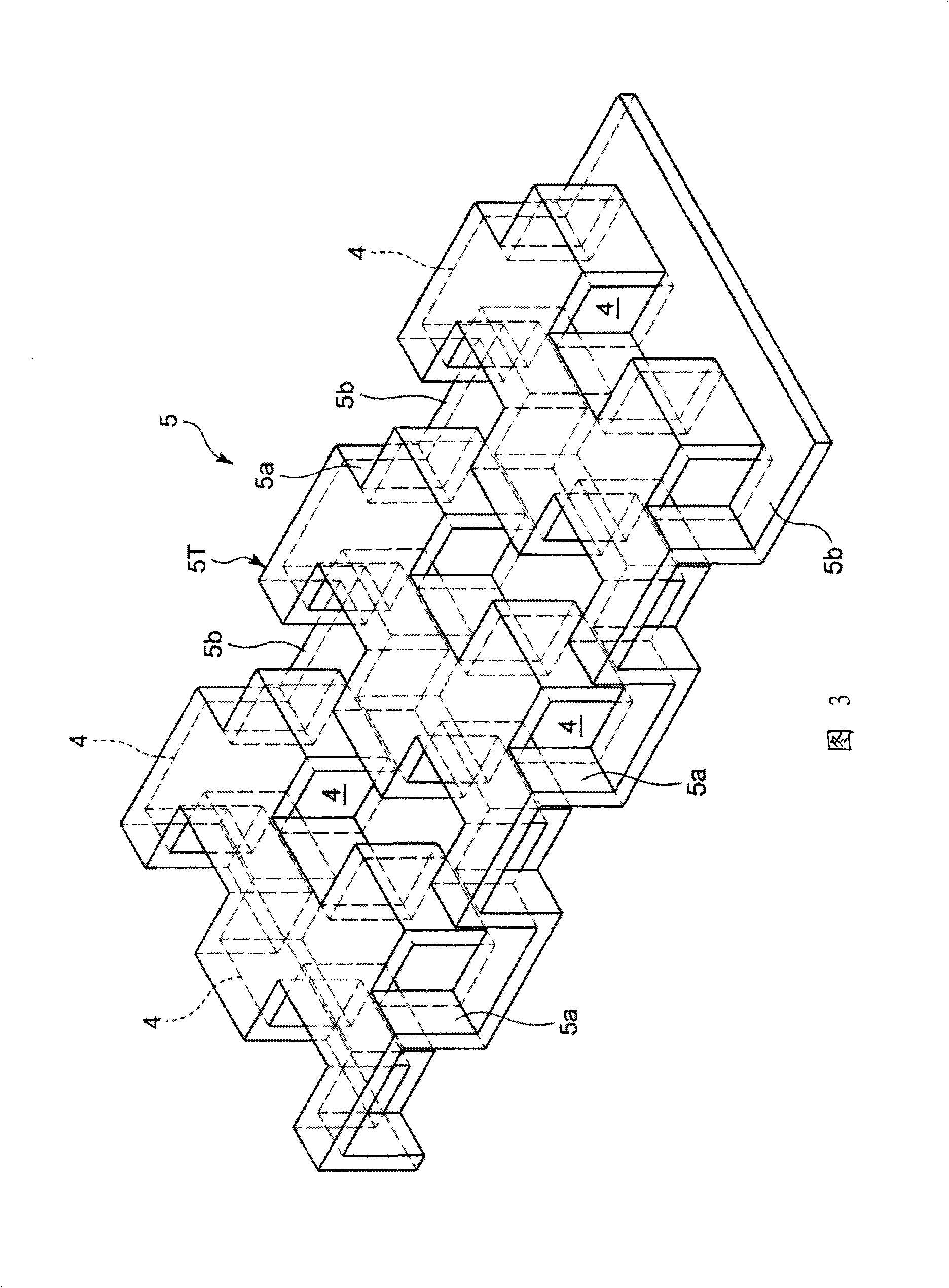

[0046] The present invention relates to a heat exchanger for exchanging heat between fluids, and aims to improve the problem of increased pressure loss when the fins are arranged perpendicular to the flow direction of the fluid, and to improve the problem of increasing the pressure loss when the fins are arranged perpendicular to the flow direction of the fluid. Fluid deflection when parallel. By arranging the fin orthogonal region where the fin is perpendicular to the flow direction of the fluid from the inlet toward the outlet, and the fin parallel region where the fin is parallel to the flow direction of the fluid from the inlet toward the outlet, the The purpose of suppressing pressure loss while improving the uneven velocity distribution of the fluid. Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

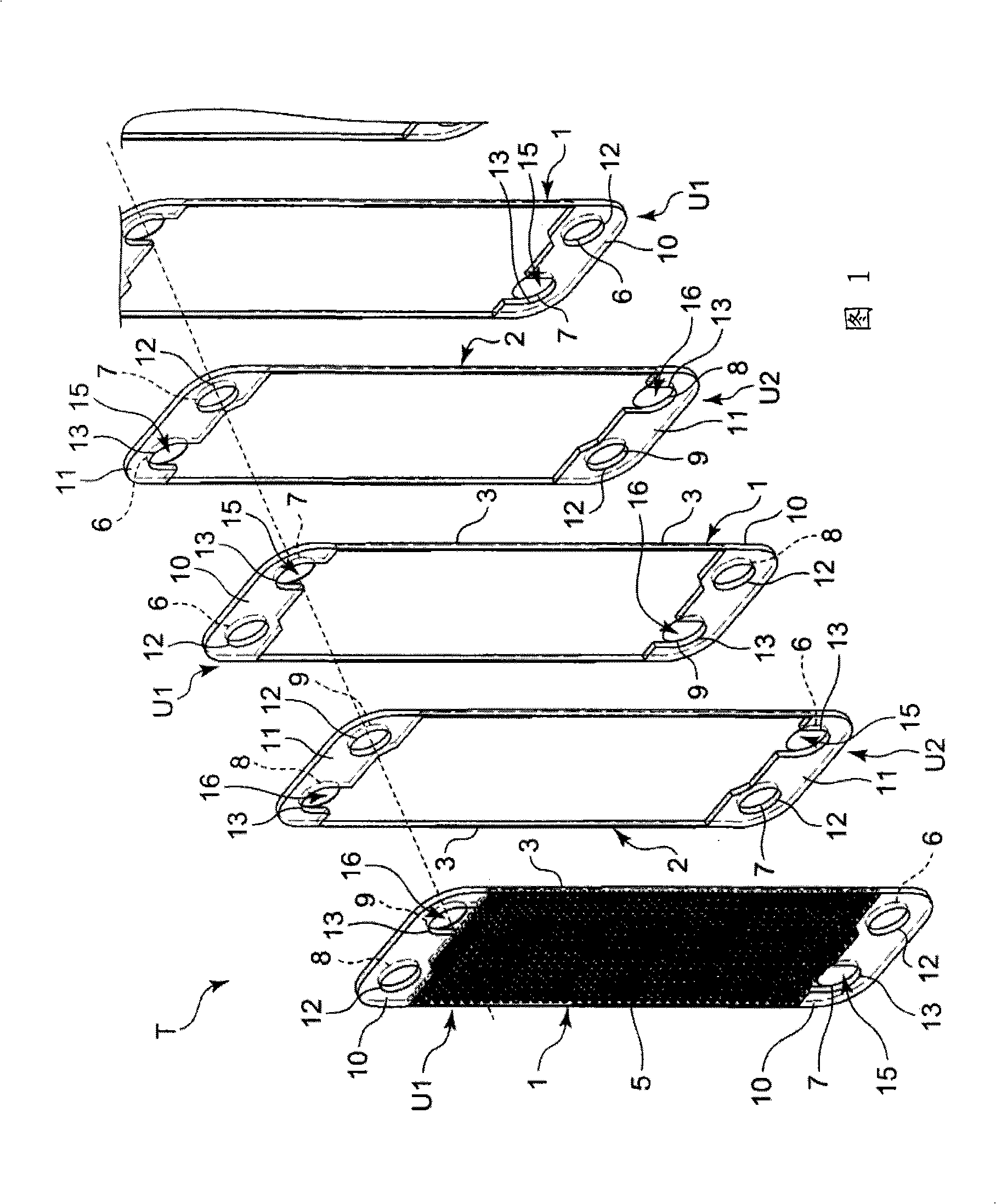

[0047] figure 1 is a perspective view schematically showing the structure of a heat exchanger according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com