Cold-headed embedded nut and manufacturing method thereof

A manufacturing method and technology of nuts, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of low utilization rate of raw materials, limitations, and inapplicability, and achieve high production efficiency, overall strength improvement, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

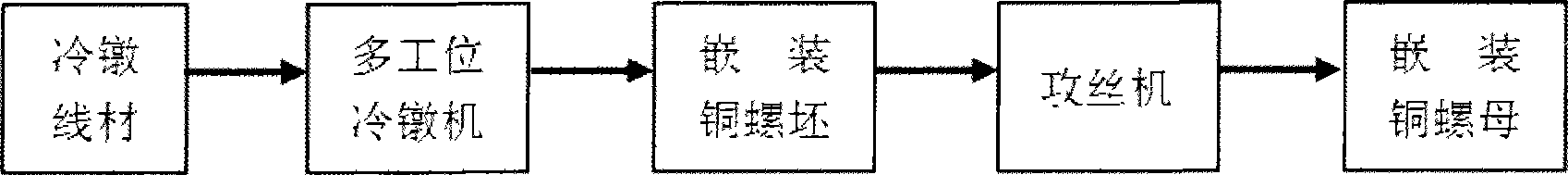

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation modes and specific operating procedures are given, but the scope of protection of the present invention is not limited to the following Mentioned examples.

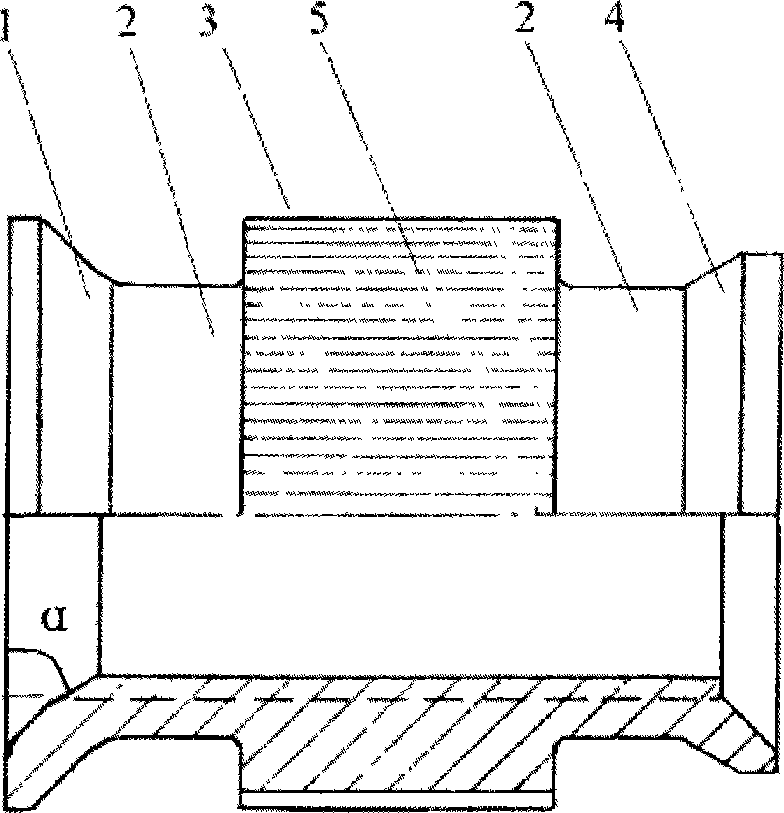

[0028] Such as figure 1 As shown, the cold forging embedded nut involved in this embodiment specifically includes: a nut mouth 1, a neck body 2, an embedded body 3, and a nut tail 4. The neck body 2 is located between the nut mouth 1 and the embedded body 3, respectively. Between the embedded body 3 and the nut tail 4, the outer part of the embedded body 3 is provided with an axial groove 5.

[0029] The inner edge of the nut mouth 1 is provided with a trumpet-shaped opening, and the angle between the opening and the horizontal plane is α=60°.

[0030] The embedded body 3 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com