Defectoscope control device

A technology of a control device and a flaw detector, which is applied in the field of high wear resistance, can solve the problems of slippage of the control roller, single specification of the detection steel ball, and high cost of the detection steel ball, so as to reduce the probability of slippage, improve the detection accuracy, and ensure the concentricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

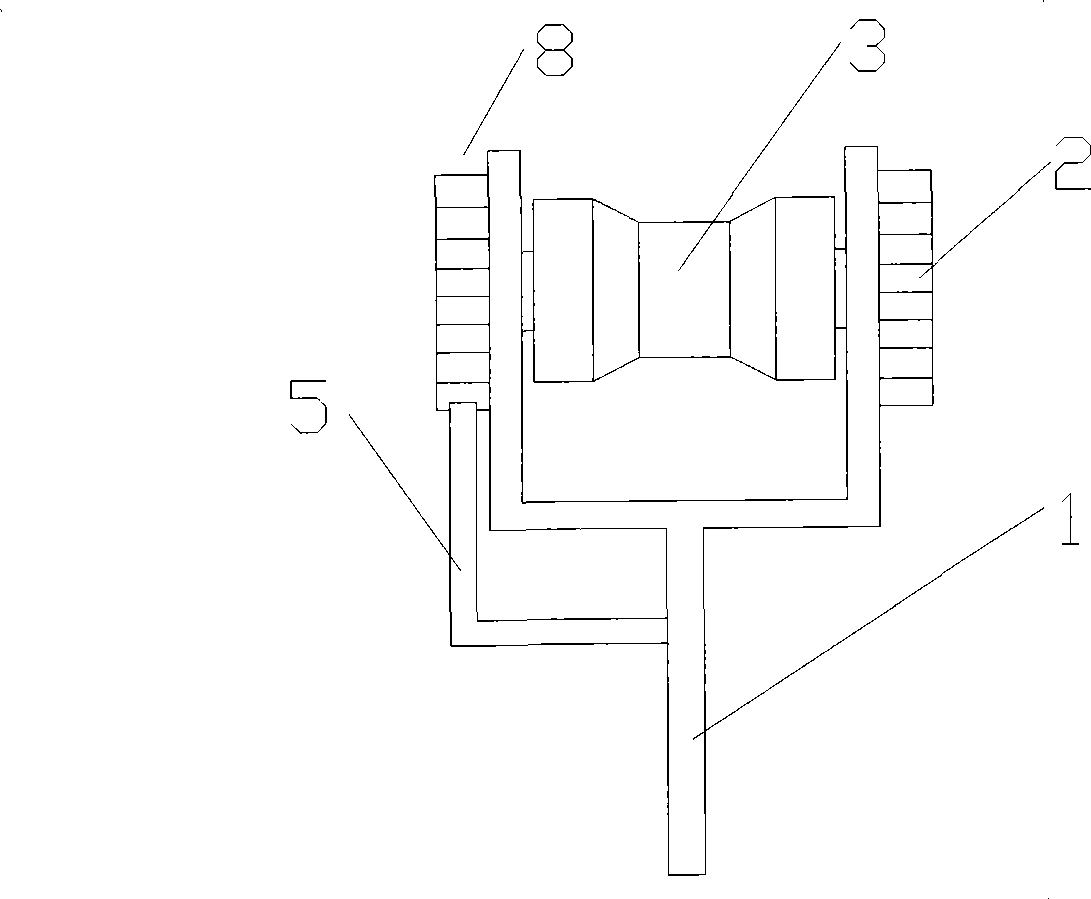

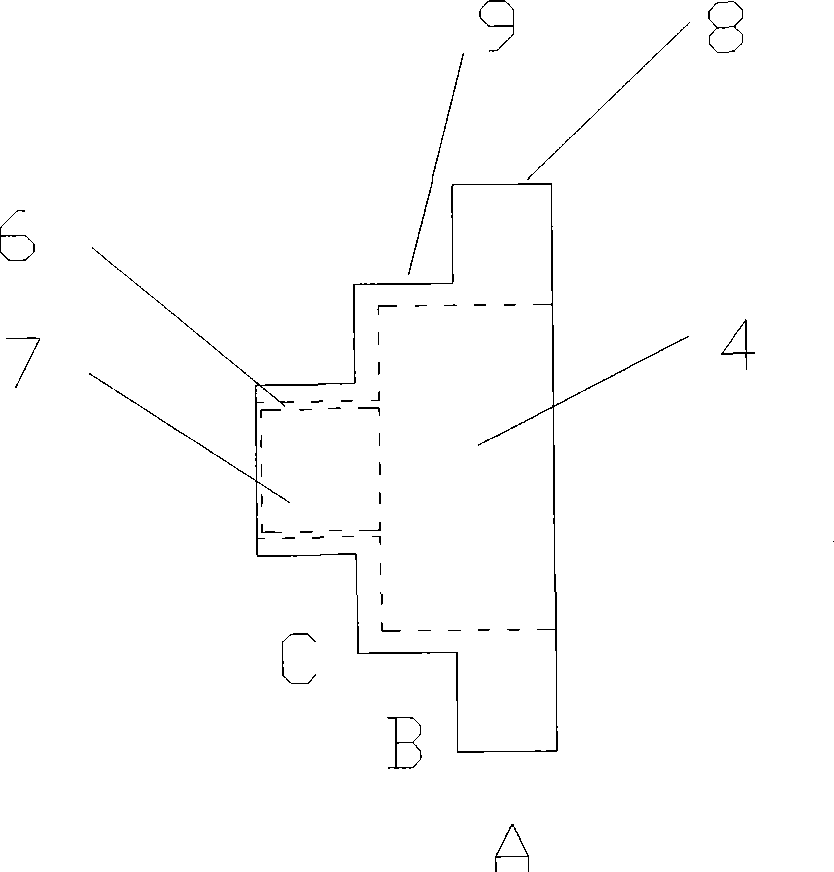

[0016] Such as figure 1 As shown, the control lever of the flaw detector is composed of a Y-shaped bracket 1, a screw 2 and a control roller 3. The Y-shaped bracket 1 is equipped with a control roller 3, and the outside of the Y-shaped bracket 1 is also provided with a control screw 2. The screw 2 as figure 1 , 2 As shown, it is composed of an inner layer and an outer layer. The outer layer is composed of three layers of stepped disks A, B, and C. The outer periphery of the A layer is provided with fine and fine British fine-toothed reverse threads 8, and the B layer is provided with reinforced threads. 9. In order to ensure the coaxiality and concentricity of the control roller 3, the inner surface of the screw 2 is also provided with a bearing embedded hole 6, and the outer surface A and B are provided with a process hole 4, and the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com