Non-contact long-stroke multi-degree-of-freedom nanometer precision working table

A nano-precision and workbench technology, which is applied in the direction of workbench, manufacturing tools, photo-plate making process exposure devices, etc., can solve the problems of large volume, increased moving mass and system inertia, complex and heavy structure, etc., to achieve resolution improvement, Improved motion resolution, dynamic characteristics and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

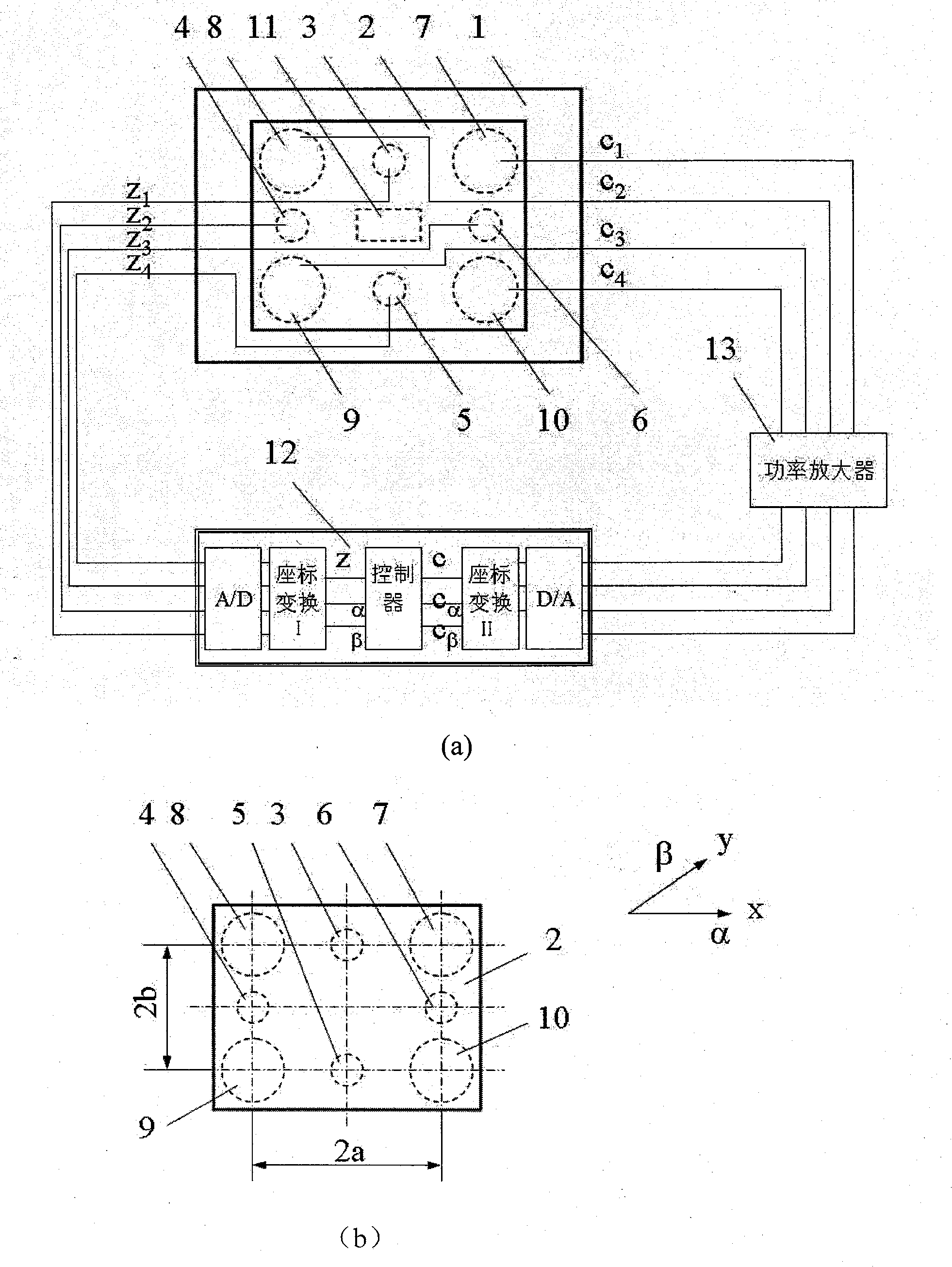

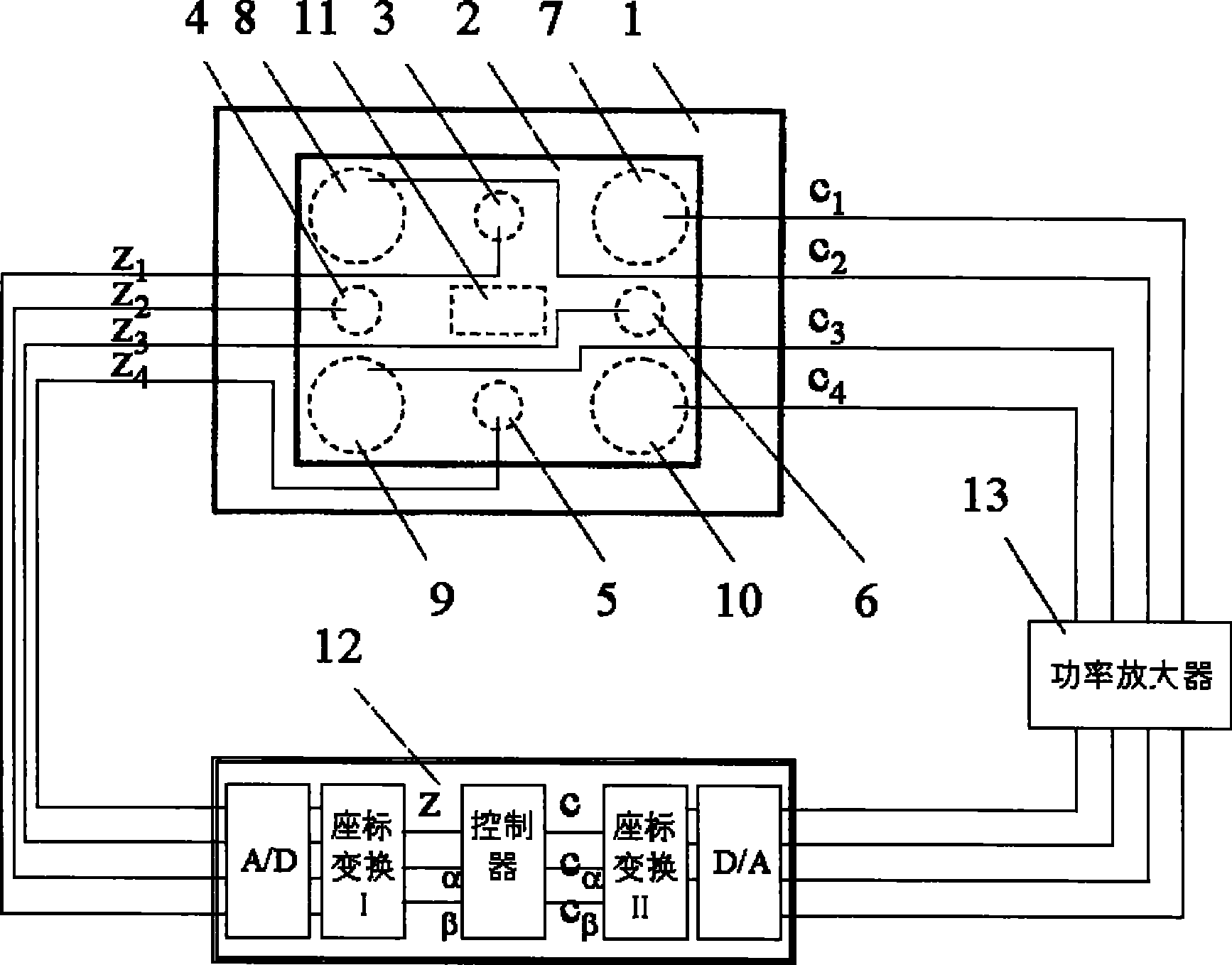

[0012] Accompanying drawing is specific embodiment of the present invention, below in conjunction with accompanying drawing content of the present invention is described in further detail:

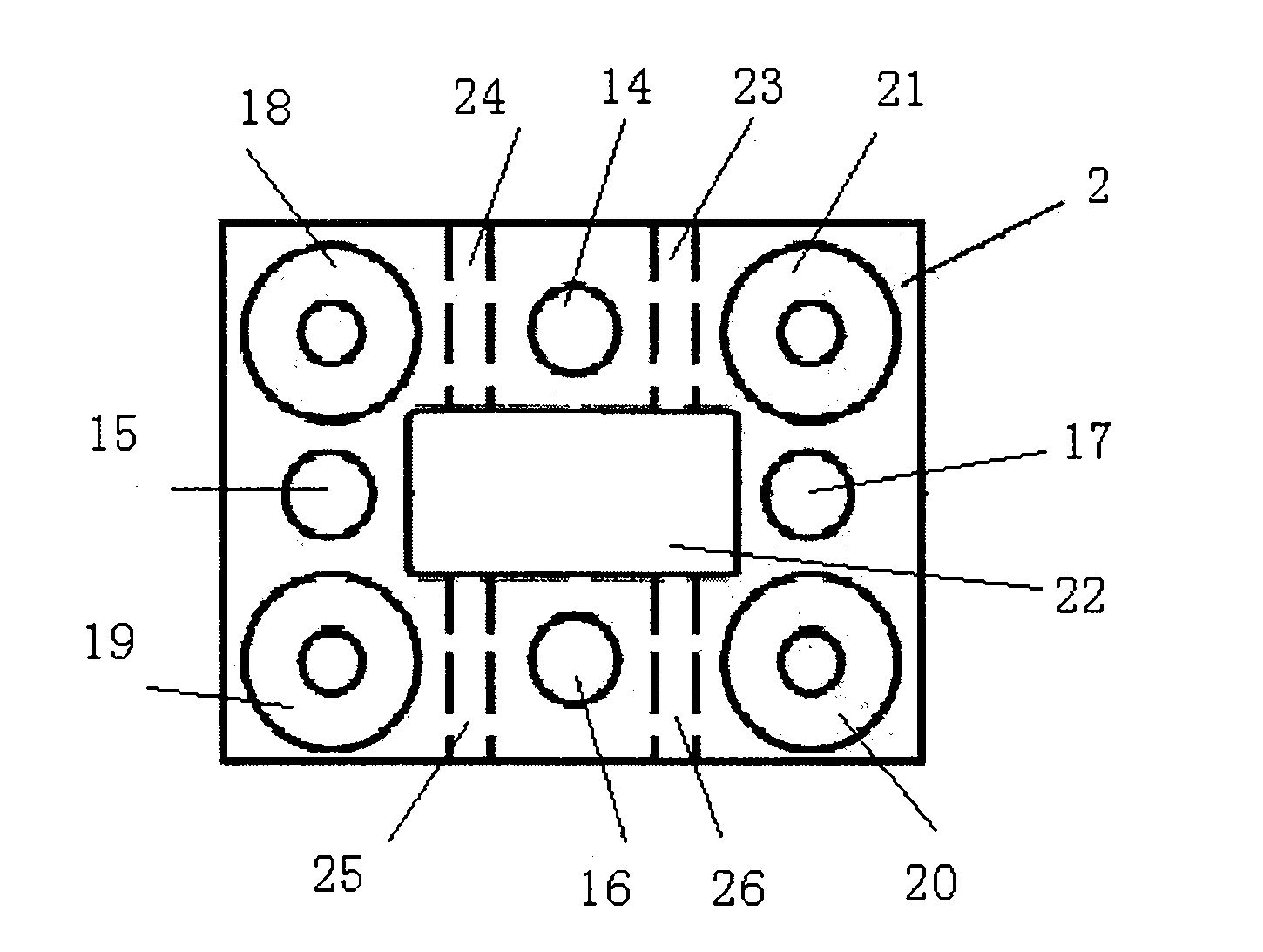

[0013] refer to figure 1 As shown, the present invention includes a workbench base 1 and a workbench moving part 2 matched with the workbench base 1, and displacement sensors 3, 4, 5, 6 are fixed on the lower surface of the workbench moving part 2, and on the workbench Coils 7, 8, 9, 10 are also fixed on the lower surface of the moving part 2, and displacement sensors 3, 4, 5, 6 and coils 7, 8 are arranged alternately and evenly. An air floating block 11 is fixed at the center of the lower surface of the workbench moving part 2 . Displacement sensors 3, 4, 5, 6 output electrical signal input to control computer 12 with analog / digital conversion (A / D) and digital / analog conversion (D / A), and control computer 12 outputs electrical signal input Power amplifier 13, the power amplifier 13 out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com