Method for manufacturing single-electron memory

A memory and single-electron technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of complex process steps, relying on electron beam lithography secondary alignment, etc., and achieve less process steps and low power consumption , The effect of low operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] The present invention is a preparation method of a single electron memory, and the specific process steps are as follows:

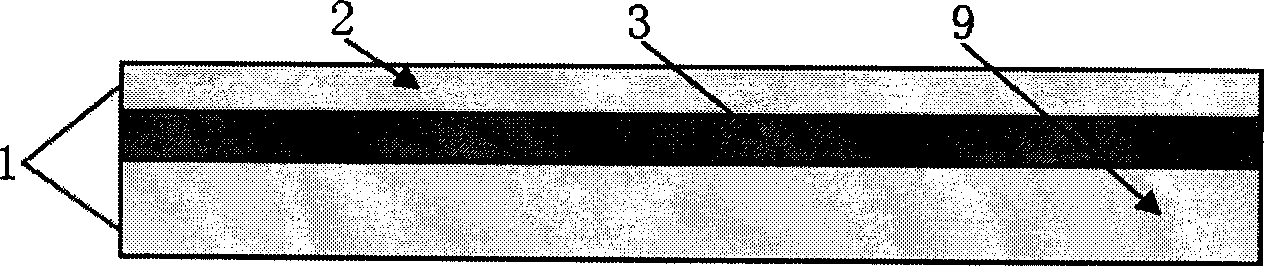

[0031] (1) Use p-type, crystal orientation 2-inch SOI as the substrate. The thickness of the top layer silicon 2 of the substrate is 50nm, the thickness of the buried oxide layer 3 is 375nm, the thickness of the bulk silicon layer is 5000+100nm, and the resistivity of the top layer silicon 2 figure 1 shown;

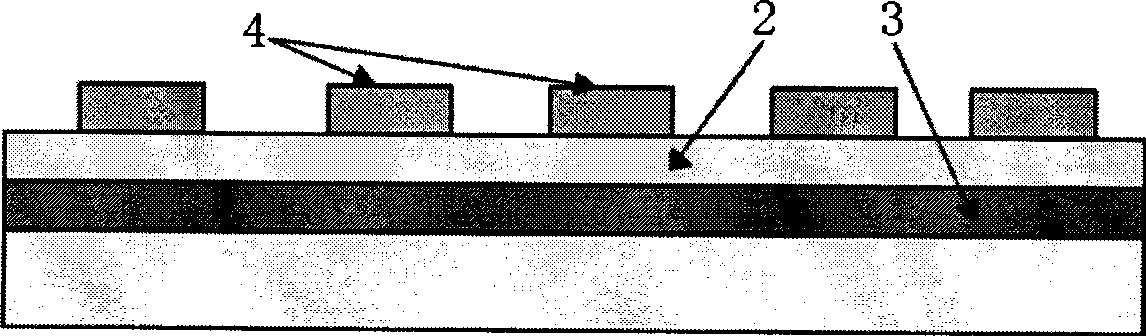

[0032] (2) Spin-coat Zep520 photoresist on the SOI substrate 1, after exposure by electron beam lithography, develop, fix, and dry with high-purity nitrogen to obtain the glue pattern and glue pattern of source, drain electrode, and conductive channel 4 On the SOI substrate 1 the shape is as figure 2 shown;

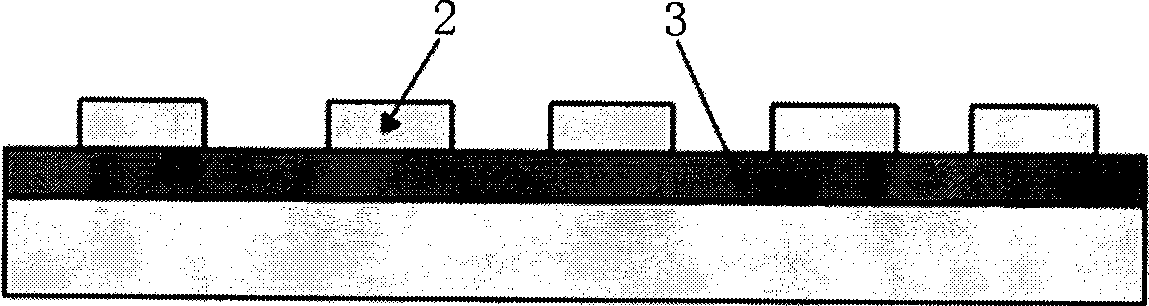

[0033] (3) Transfer the glue pattern 4 to the top layer silicon 2 by wet etch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com