Method for manufacturing single-electron memory

A memory and single-electron technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of relying on electron beam lithography for secondary alignment and complex process steps, and achieve low power consumption and few process steps , the effect of large consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0030] The present invention is a method for preparing a single-electron memory, and the specific process steps are as follows:

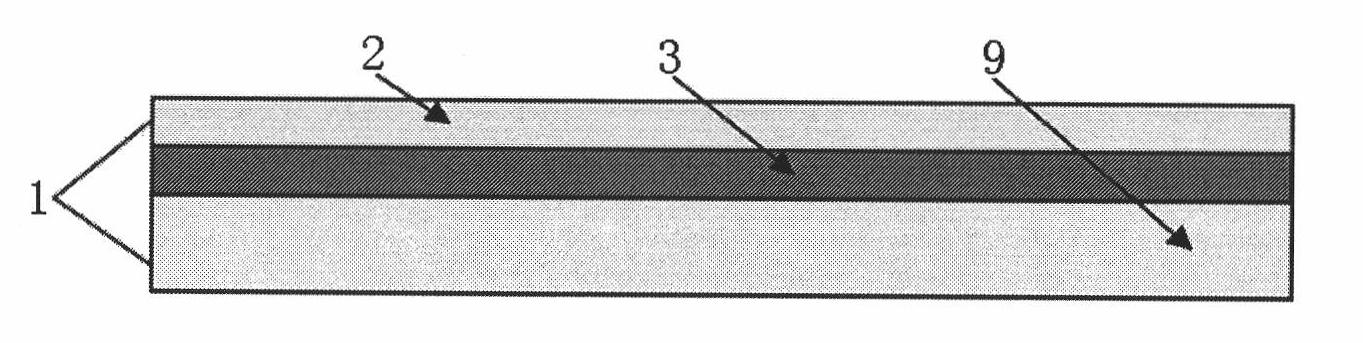

[0031] (1) Using p-type, The crystal-oriented 2-inch SOI is used as the substrate. The top silicon 2 of the substrate is 50nm thick, the buried oxide layer 3 is 375nm thick, the bulk silicon layer is 5000±100nm thick, and the resistivity of the top silicon 2 is figure 1 Shown

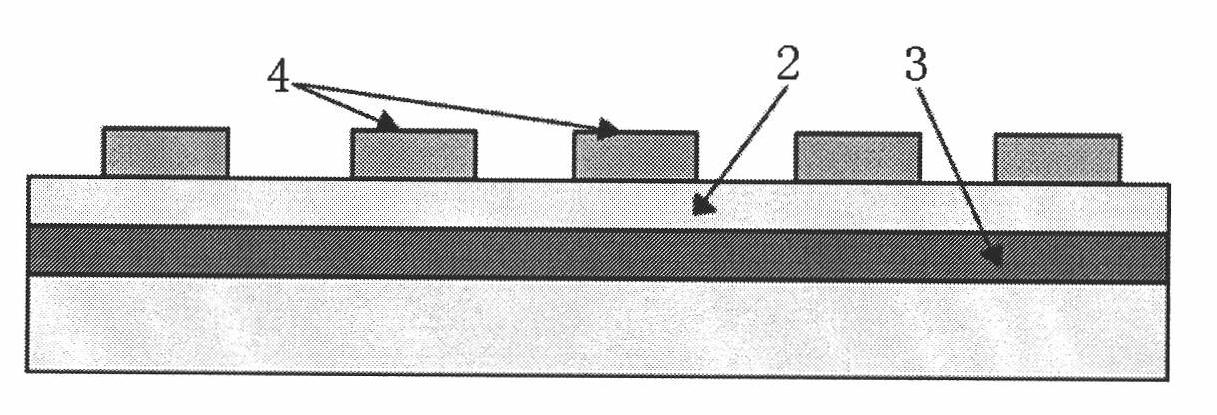

[0032] (2) Spin-coating Zep520 photoresist on SOI substrate 1, after exposure by electron beam lithography, developing, fixing, and drying with high-purity nitrogen to obtain the glue pattern of source, drain electrode, conductive channel, glue pattern 4 The shape on the SOI substrate 1 is like figure 2 Shown

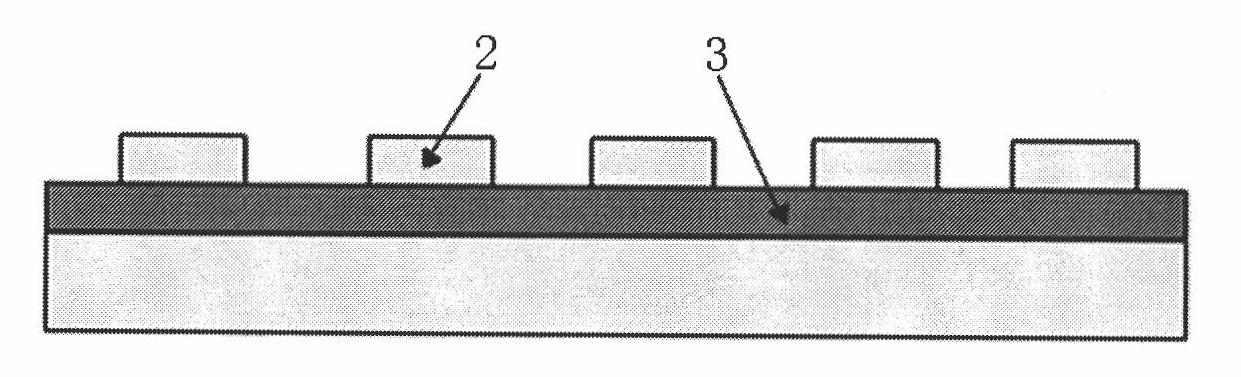

[0033] (3) Use wet etching to transfer the glue pattern 4 to the top layer silicon 2. The wet etching solution uses HNO 3 , H 2 O and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com