Disk brake and brake lining for the same

A technology of disc brakes and brake linings, which is applied to the components of the brakes, the type of brakes, the brakes in the axial direction, etc., can solve the problems of residual braking torque, increased wear of brake linings, and increased fuel consumption, etc. To achieve the effect of preventing noise formation and preventing sticking/jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

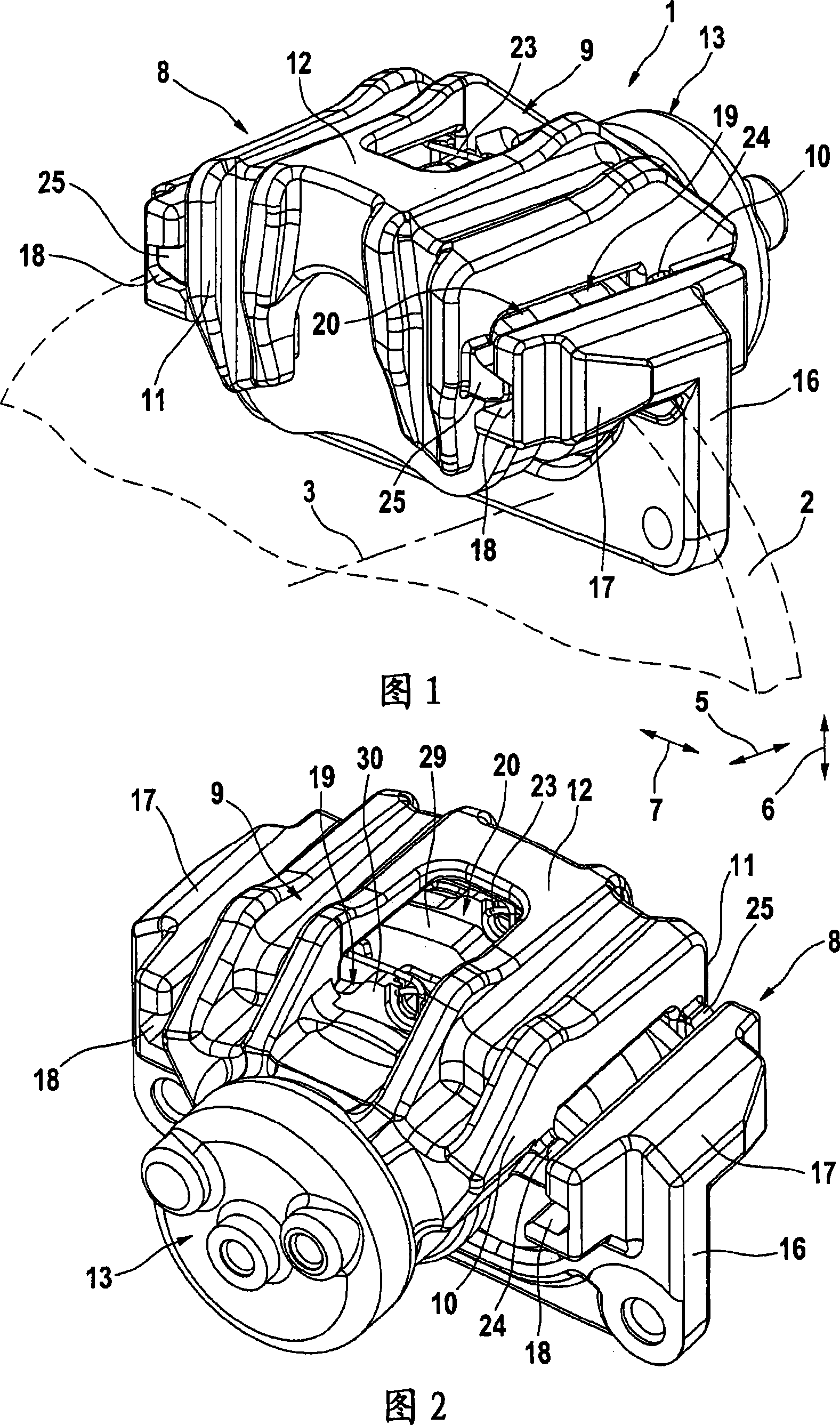

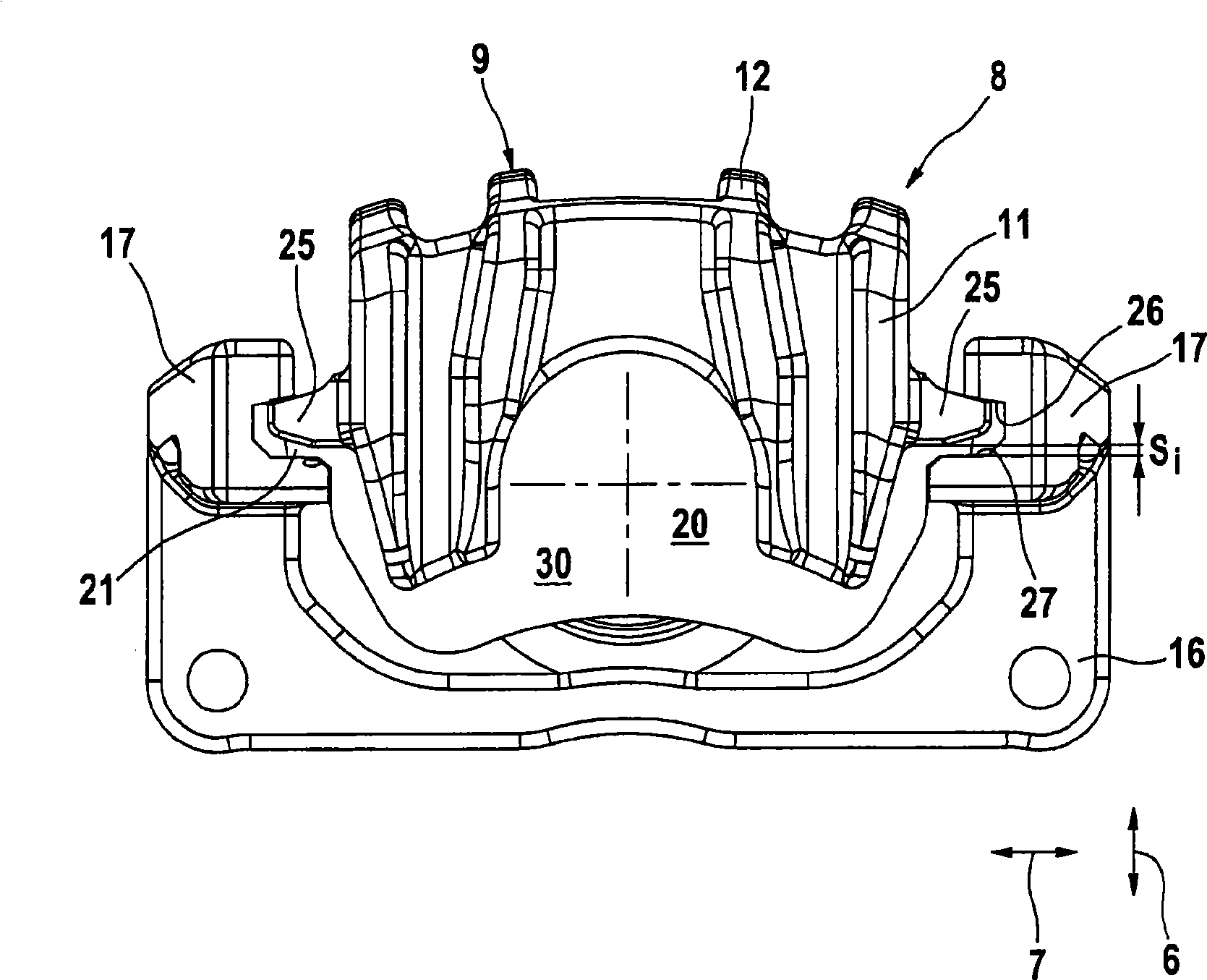

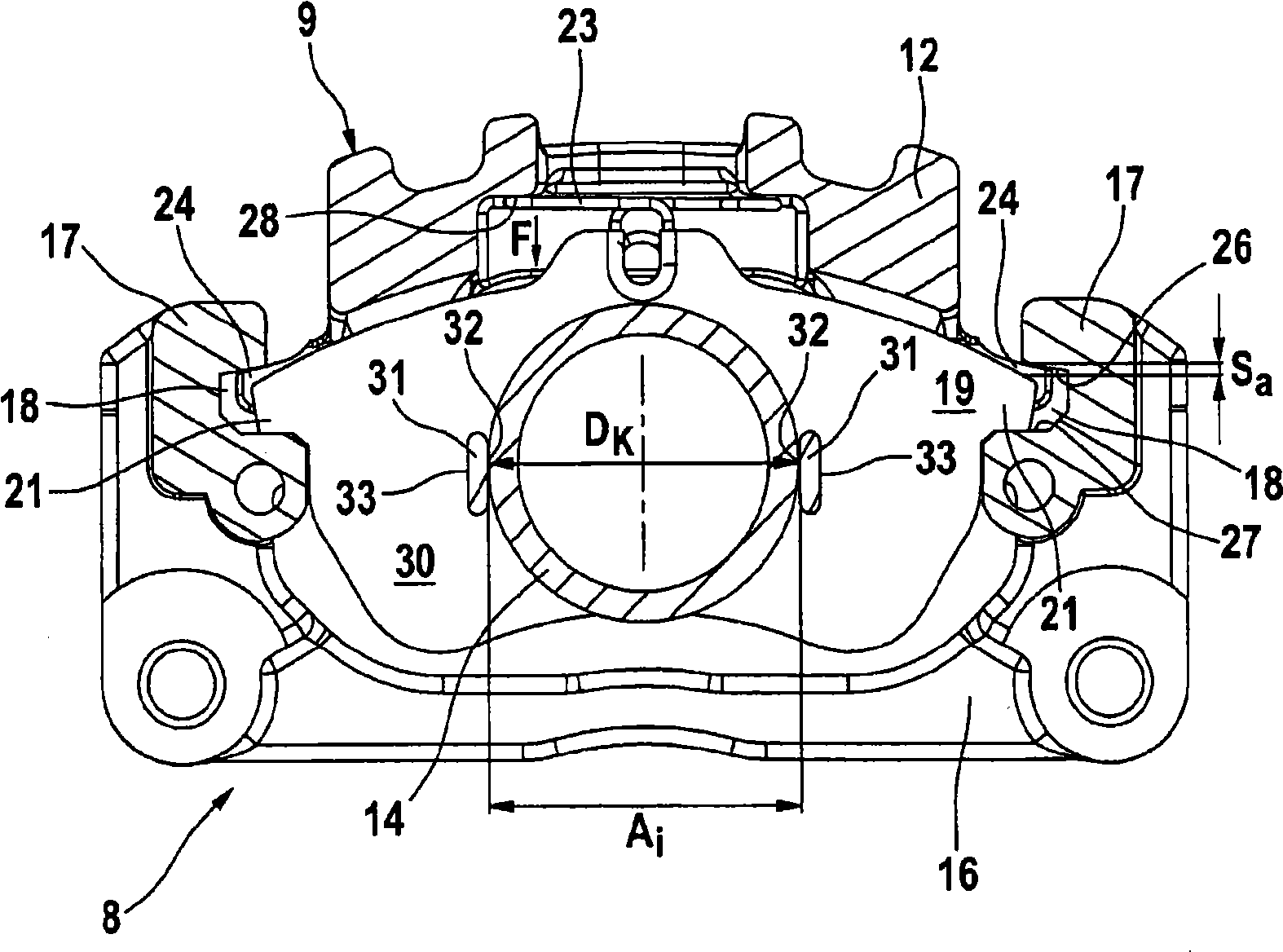

[0029] 1 to 7 and FIGS. 8 and 9 show a first embodiment and a second embodiment of brake calipers 8, 8' of a disc brake 1 in different views and sectional views. In addition, in Figure 10 and 11 A similar embodiment of a brake caliper 51 of a disc brake 50 is shown in , which is disclosed independently and independently within the framework of the present invention. Since all the exemplary embodiments are fundamentally constructed similarly, the functional principle of the disc brake 1, 1', 50 will be explained jointly below.

[0030] The brake calipers 8 , 8 ′, 51 engage around a schematically shown brake disc 2 , which is mounted rotatably about an axis of rotation 3 . The axial direction 5 , the radial direction 6 and the circumferential direction 7 are aligned relative to the axis of rotation 3 . The caliper housing 9, 9', 54 comprises an axially inner housing branch 10, 10', 55 which also comprises an actuating device 13 and which faces the vehicle in the installed st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com