Flat commutator

A commutator and plane technology, applied in the direction of current collectors, rotating current collectors, electrical components, etc., can solve problems such as breakage or shearing of partitions 9, and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Identical components and components with the same function are provided with the same reference symbols in the figures.

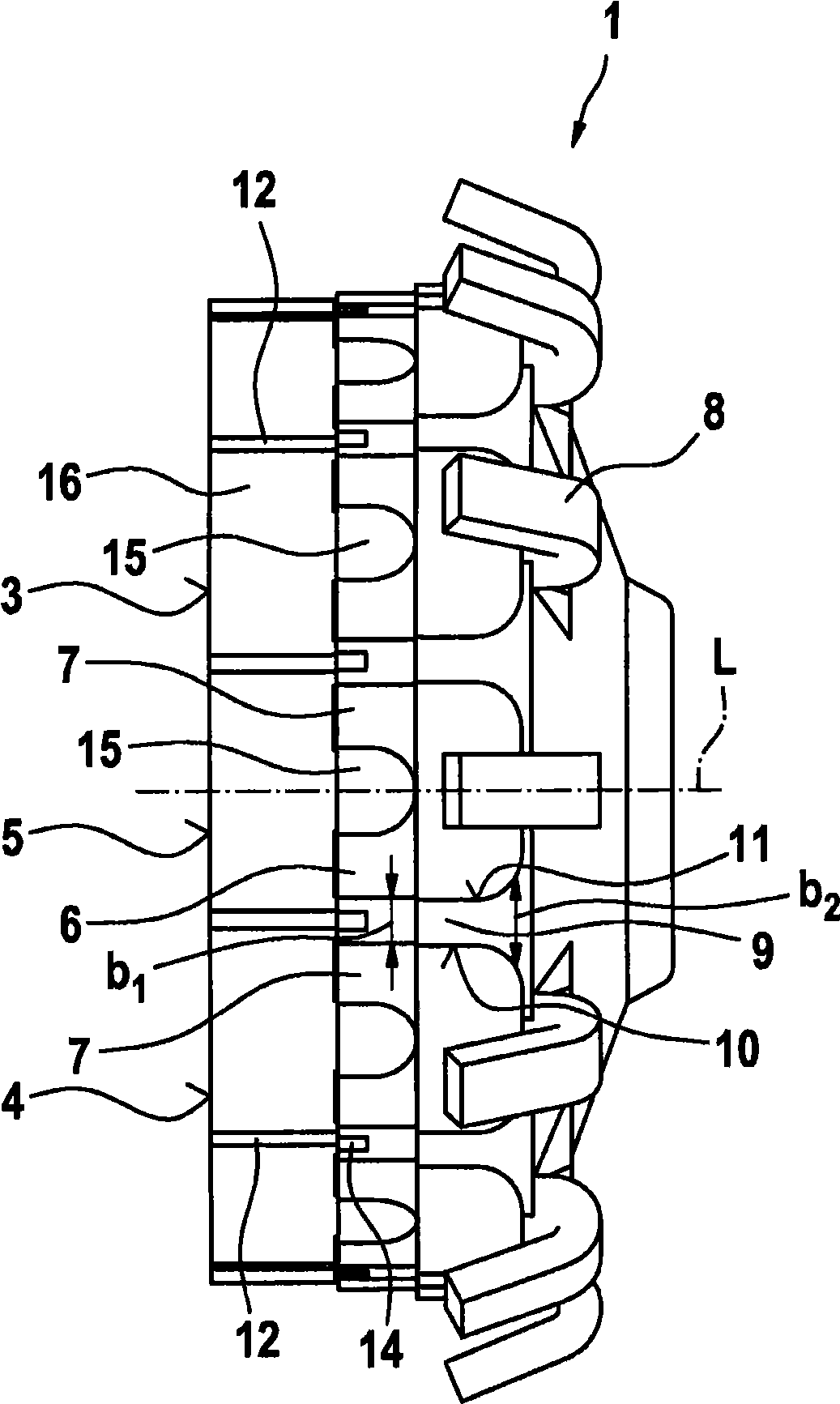

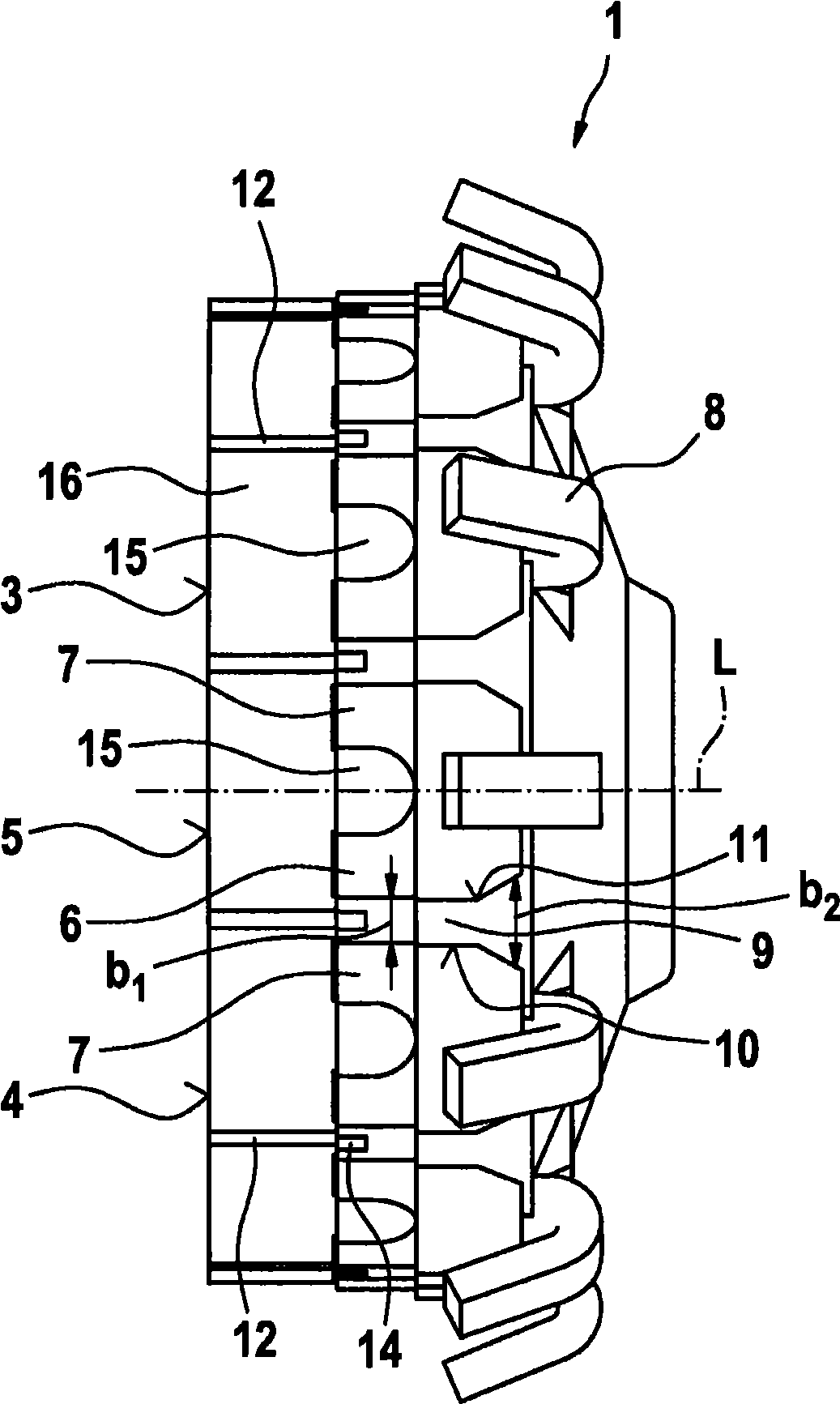

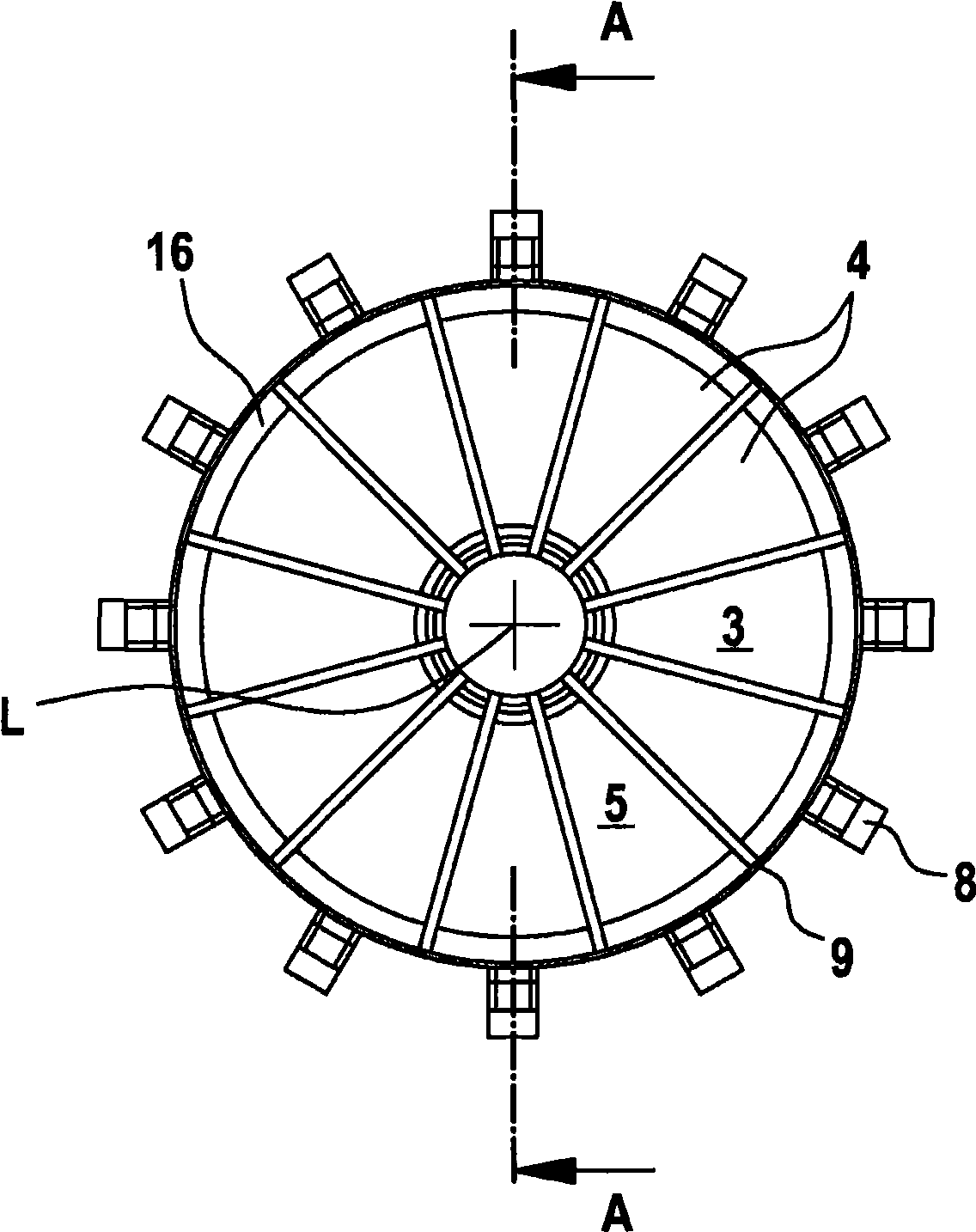

[0022] exist figure 1 designates a planar commutator for an otherwise known electric machine. In the assembled state, the planar commutator 1 is passed through by an armature shaft in the direction of its longitudinal axis L and connected thereto in a rotationally fixed manner.

[0023] The planar commutator 1 has a plastic hub body 2 . exist image 3 A plurality of contact segments 4 made of carbon spaced apart from one another are arranged on the end face 3 shown in plan view in the circumferential direction. Together they form an end-face, planar brush contact surface for at least one brush of the electric machine (not shown).

[0024] Each contact segment 4 is connected with a plate-like extending in the radial direction, in Figure 4 As shown in , the radial section 13 of the segment support part 6 is soldered and thus connected firmly and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap