Framework of glass brick wall and construction method thereof

A construction method and technology of glass bricks, applied in the direction of walls, long-strip structural members for load-bearing, structural elements, etc., can solve the problems of inconvenience, general products and methods without suitable structures and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

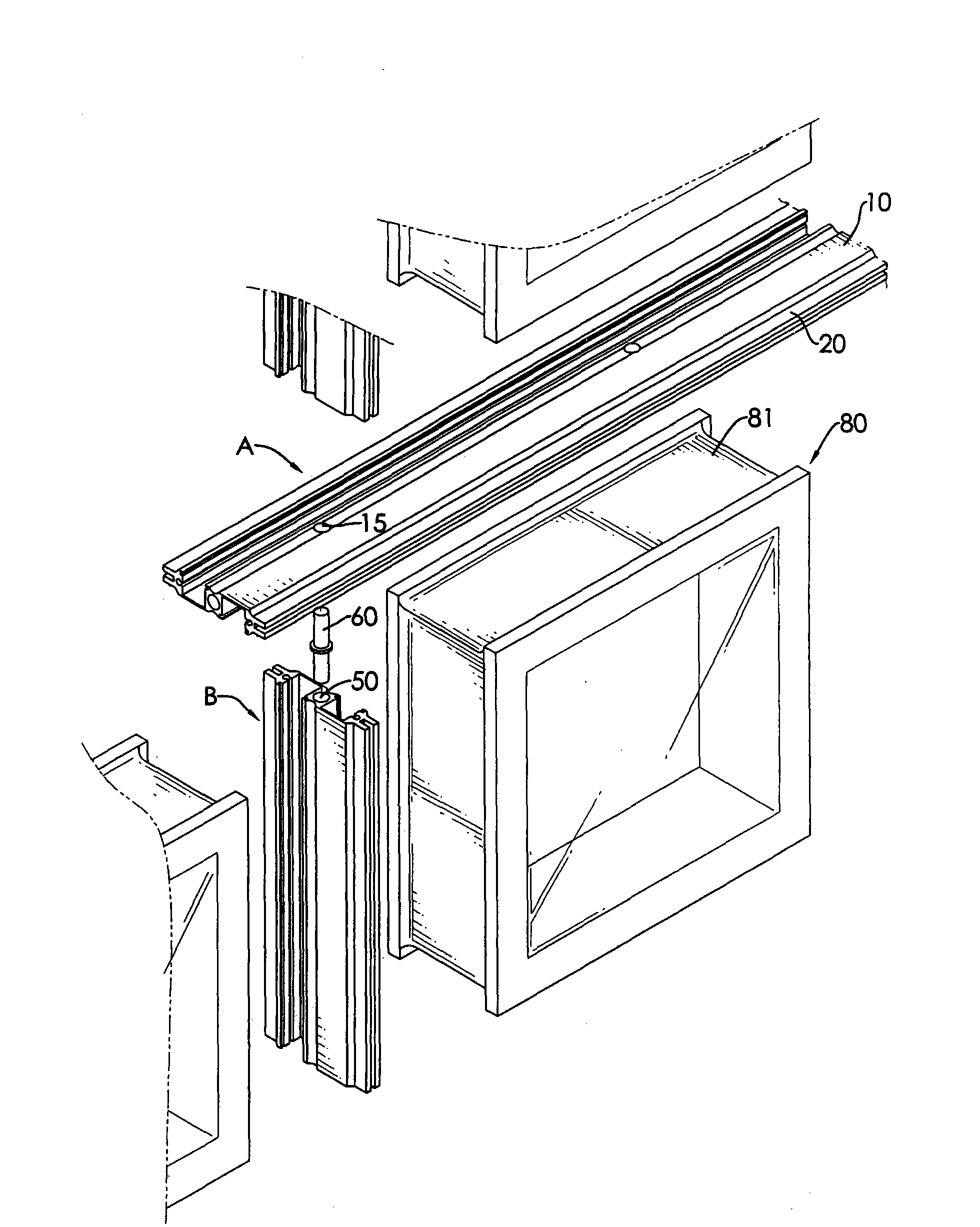

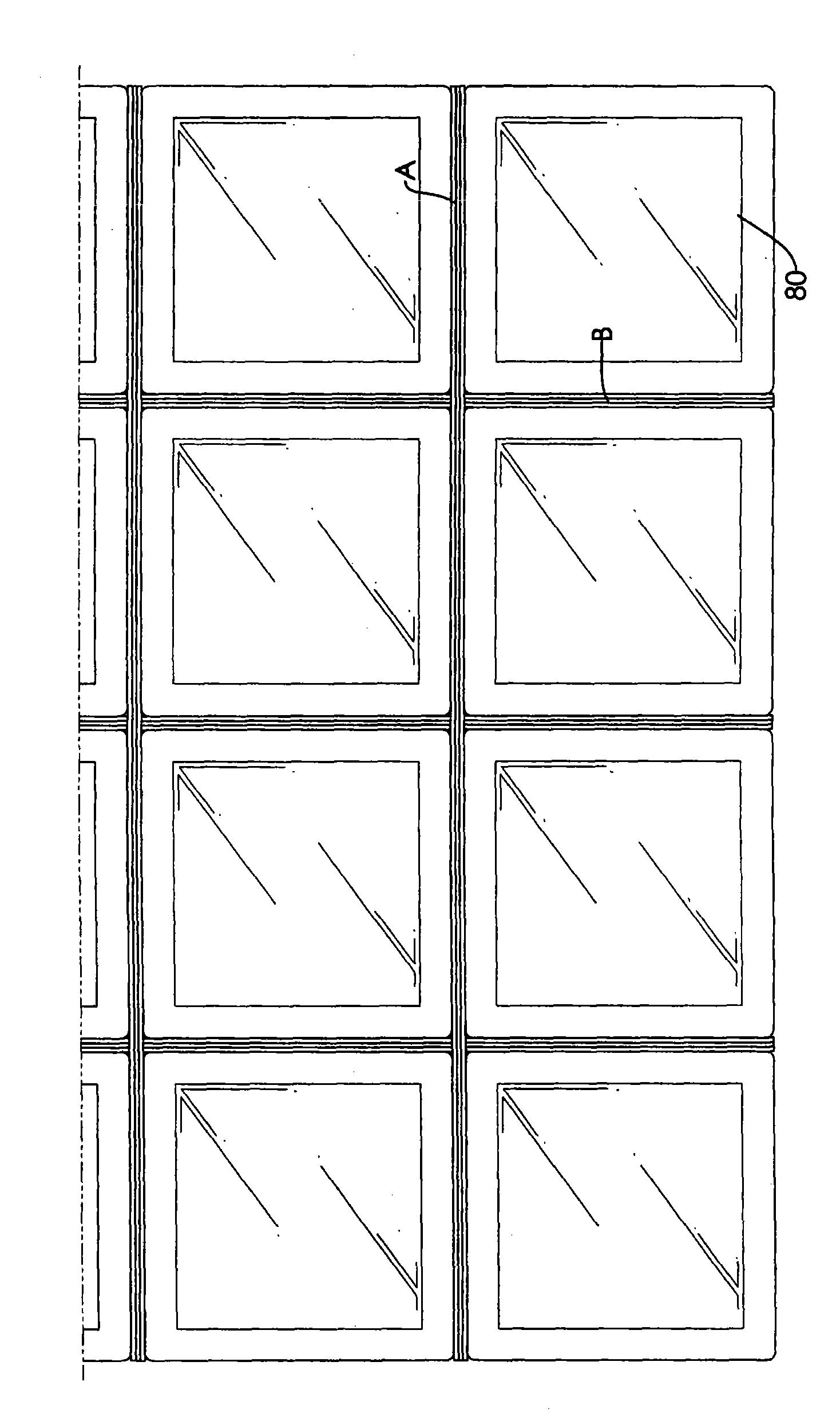

[0035] For further elaborating the technical means and effect that the present invention takes for reaching the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the skeleton of the glass brick wall proposed according to the present invention and its construction method its specific implementation, structure, Features and their functions are described in detail below.

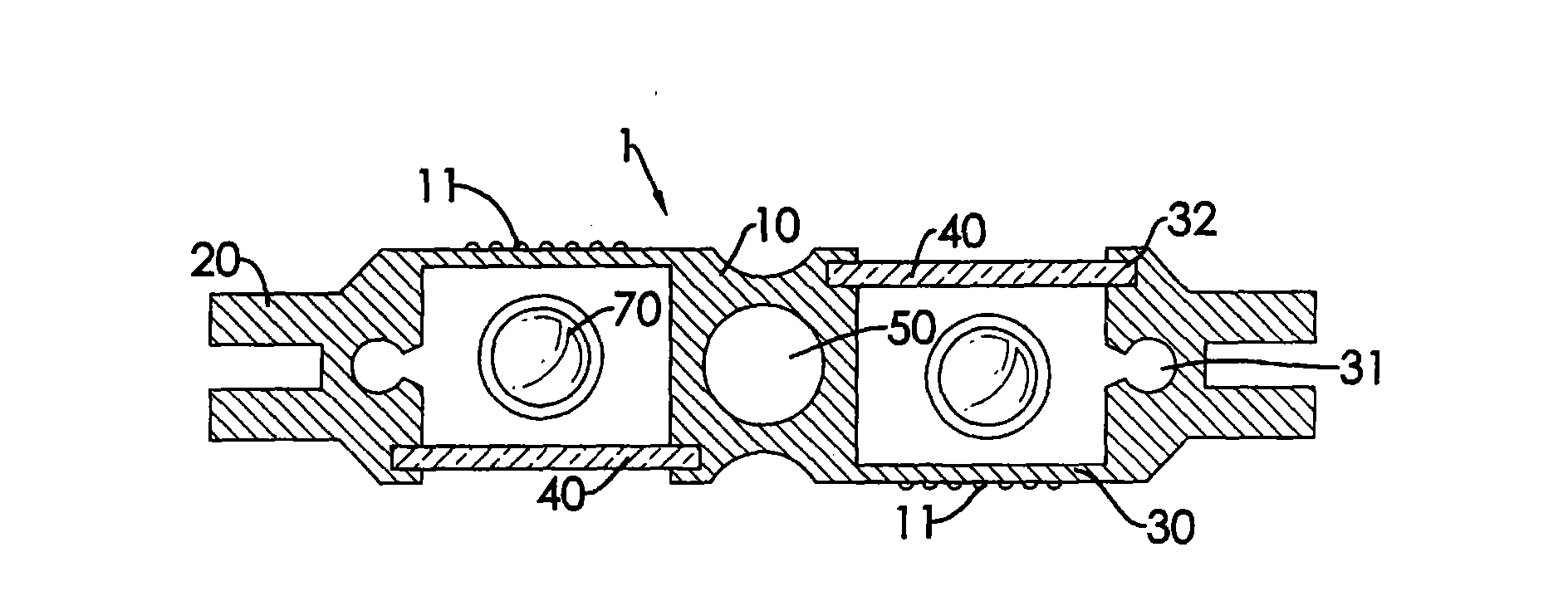

[0036] Please see figure 1 and figure 2 As shown, the skeleton 1 of the glass brick wall of the present invention is mainly used in the stacking of glass brick walls, and it may further include a body 10 , two side wings 20 , two light grooves 30 , two cover plates 40 and a pin hole 50 .

[0037] The above-mentioned main body 10 is a long plate body, and its width corresponds to the groove 81 at the side edge of the glass brick 80, and protruding lines 11 can be further provided on the two plate surfaces to increase the friction force on the surface , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com