Short arc type high voltage discharge lamp

A high-pressure discharge lamp and short-arc technology, which is applied to high-pressure discharge lamps, discharge lamps, gas discharge lamps, etc., can solve the problems of core wire 105 falling off, reduced lamp illumination, and high resistance, so as to achieve easy plastic deformation and improve contact. , the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

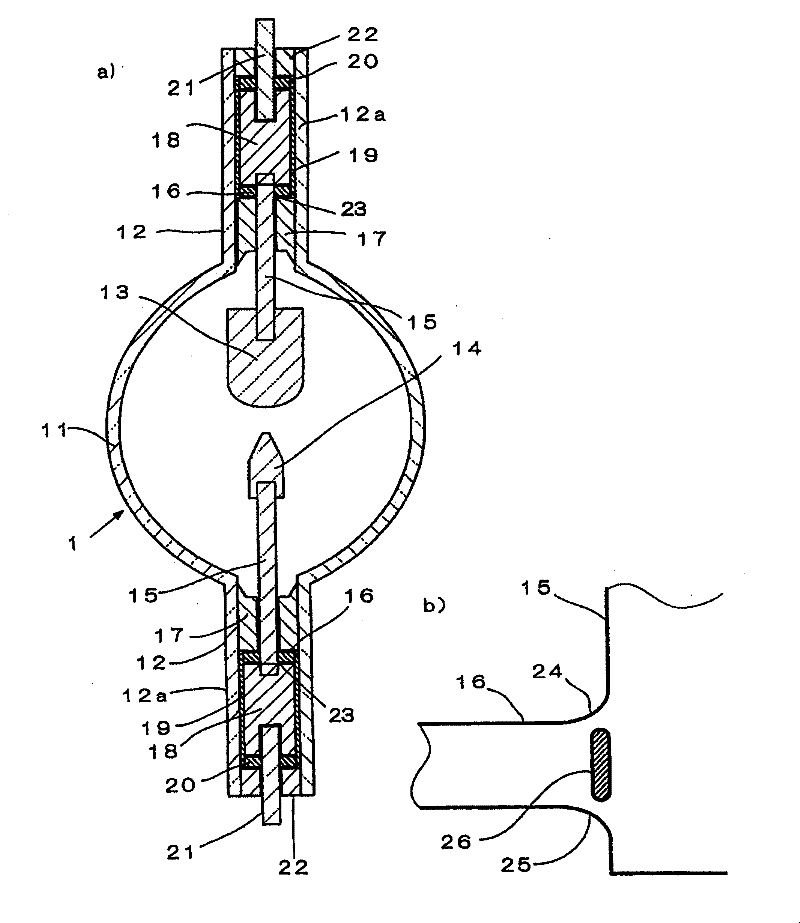

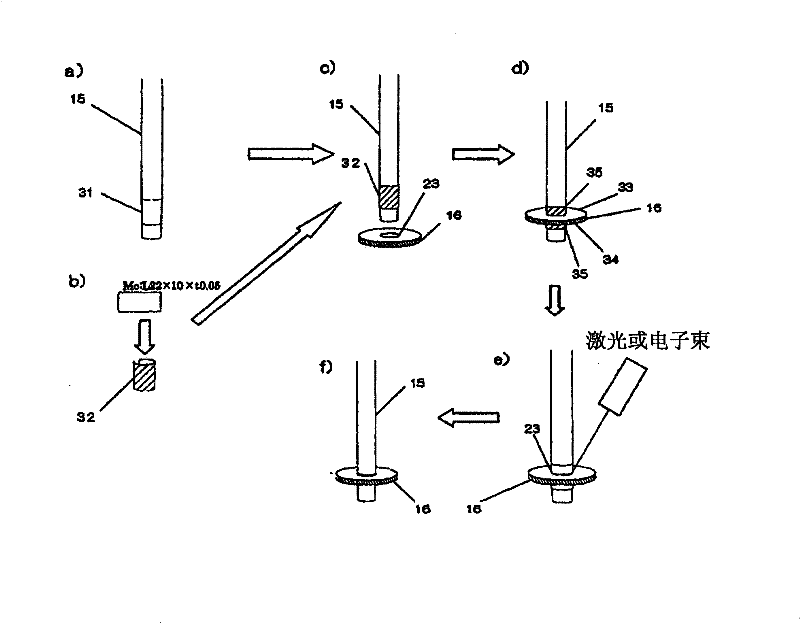

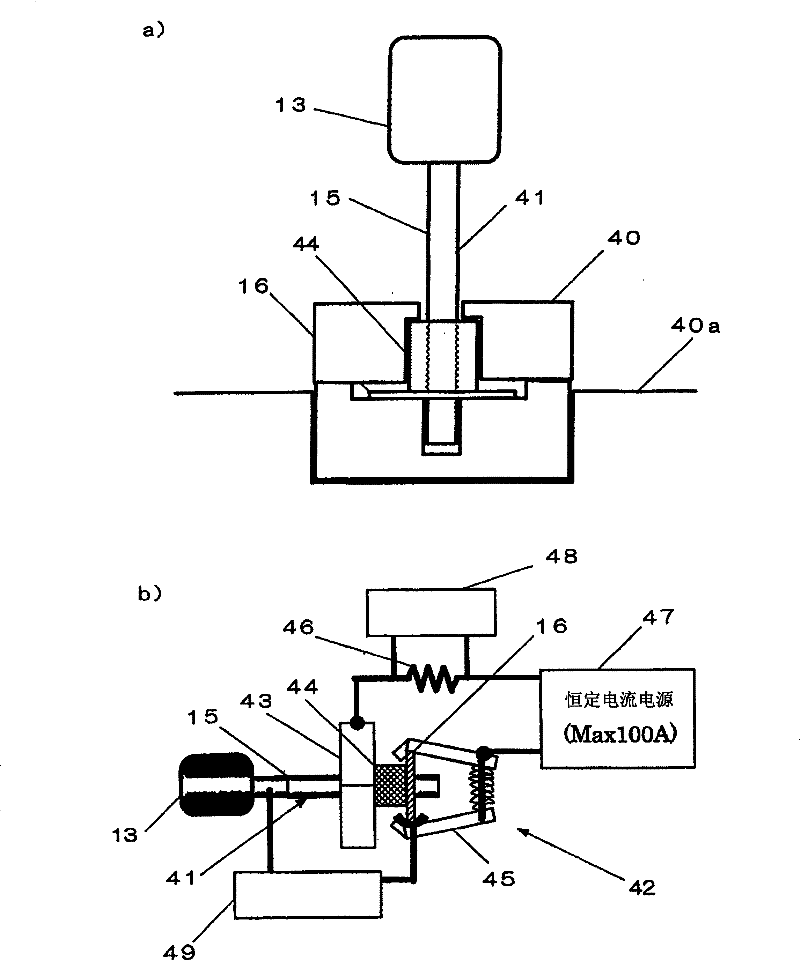

[0021] figure 1 Shows the first embodiment of the present invention. figure 1 (a) shows a schematic cross-sectional view of the short-arc high-pressure discharge lamp of the present invention. The short-arc high-pressure discharge lamp 1 consists of a tube part 11 forming a discharge space; a sealing tube part 12 protruding from both ends of the tube part 11; An anode 13 and a cathode 14 are formed. And, this sealing pipe part 12 is made up of the following parts: hold the core wire 15 of this anode 13 or this cathode 14 at one end; and arranged to substantially abut against the first metal plate 16 made of quartz glass cylindrical body 17; through the first metal plate 16 and the columnar body 18 made of quartz glass arranged opposite to the cylindrical body 17; The side surface of the columnar body 18 is arranged in close contact with the Mo metal foil 19 welded to the first metal plate 16; the second metal plate 20 welded to the other end of the metal foil 19; connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com