Bone model, bone filler and process for producing bone filler

A manufacturing method and model manufacturing technology, applied in the fields of skulls, bone implants, medical science, etc., can solve the problems of damage to bone fillers, weak strength of bone fillers, and difficulty in knowing how much the bone is deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

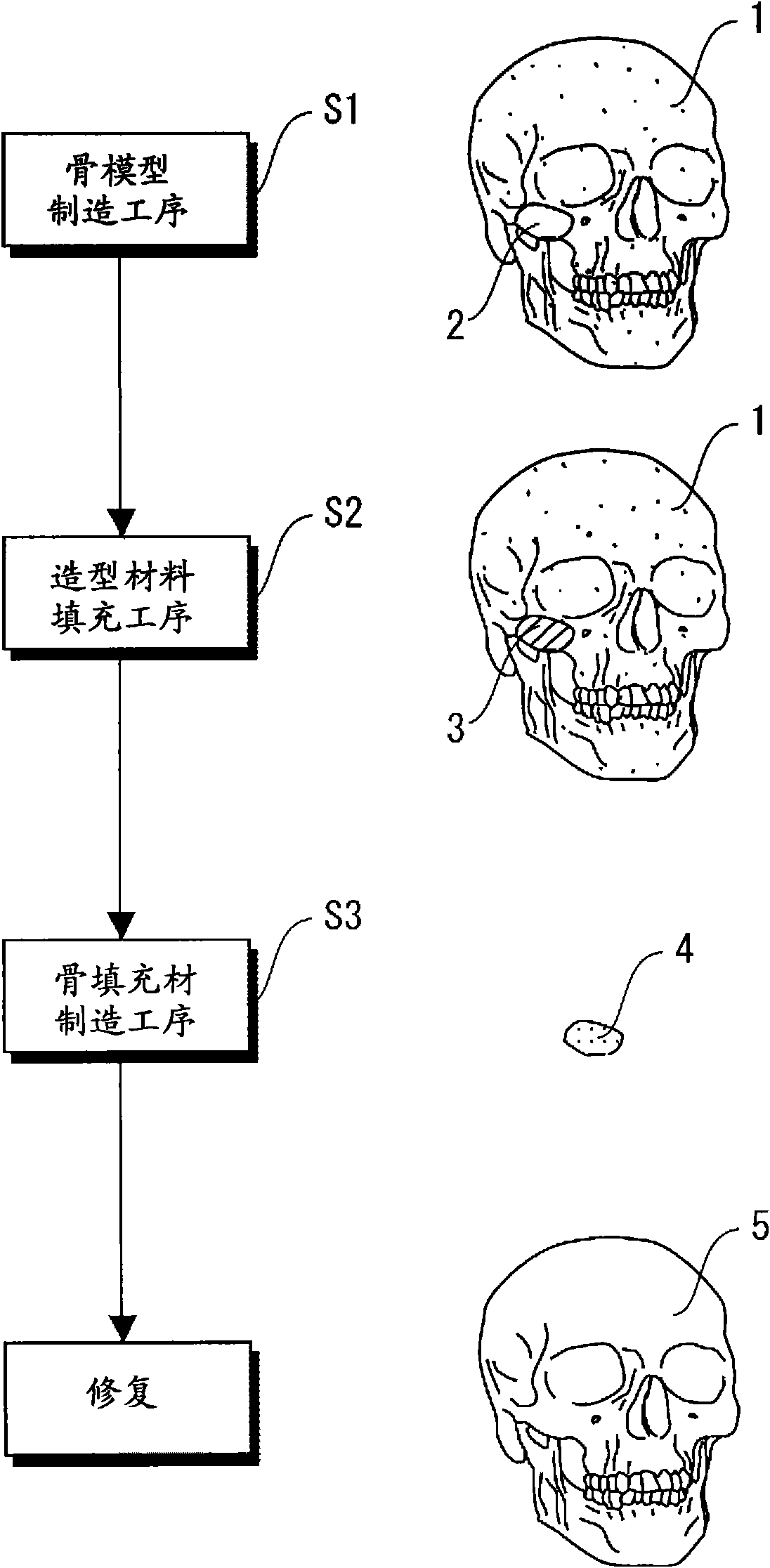

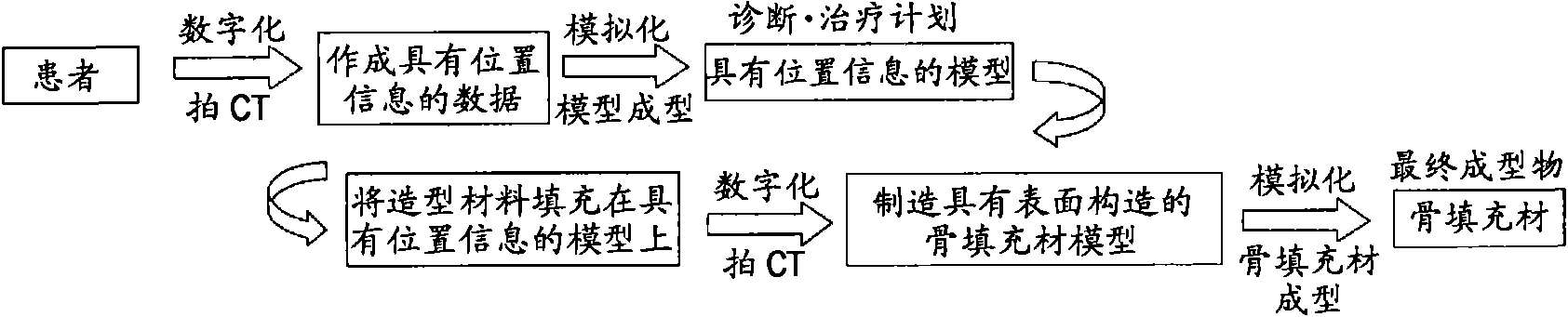

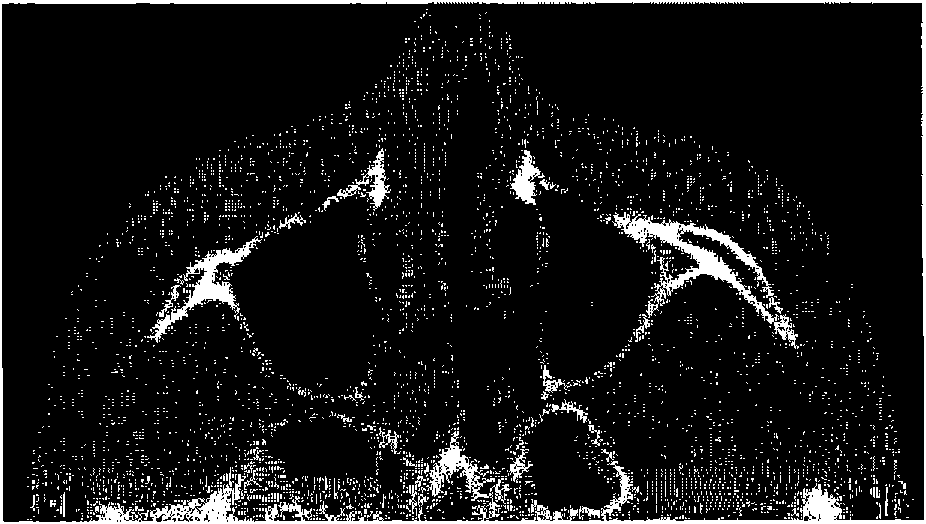

[0227] The following examples illustrate the present invention in detail. The present invention is not limited to the following examples, and can be implemented by appropriately adjusting the contents disclosed in this specification. figure 2 is a schematic diagram of each step in this embodiment. That is, in this embodiment, bone deformation is corrected by manufacturing a bone filling material for correcting bone deformation of a patient with bone deformation and implanting the bone filling material in a patient with bone deformation. like figure 2 As shown, the manufacturing method of the bone filling material in this embodiment is a method of digitizing the patient's skull (front half) by CT imaging. FIG. 3 is a diagram showing a CT image captured by CT, which replaces the accompanying drawings. Fig. 3(a) is a CT image of the cheek part, and Fig. 3(b) is a CT image of the jaw part. As shown in Fig. 3(a) and Fig. 3(b), the bone of the patient whose CT image was taken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com