Dust discharge outlet for cyclone separating device of dust collector

A cyclone separator and discharge port technology, applied in suction filters and other directions, can solve the problems of reduced downward rotation force of incoming airflow, reduced separator function, and small household garbage separation effect, so as to improve the separation effect and change the flow field distribution. , the effect of reducing airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

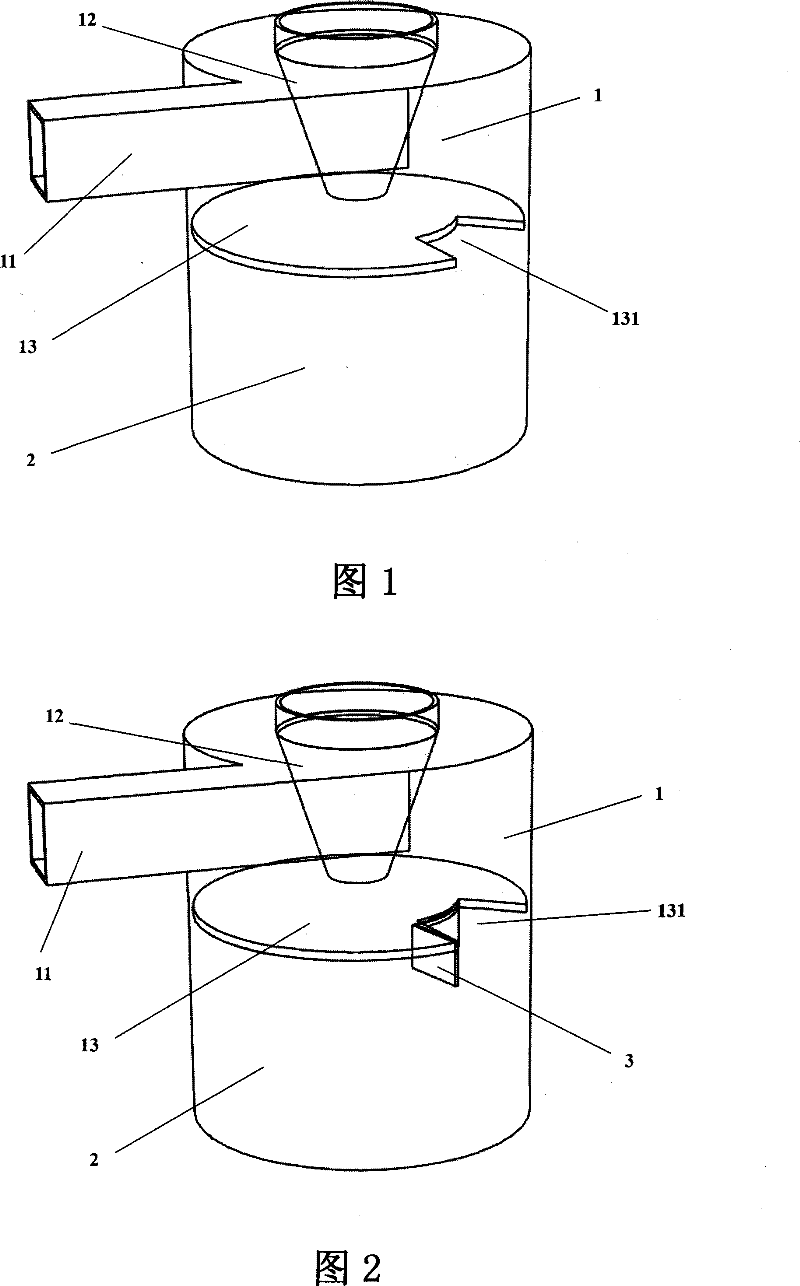

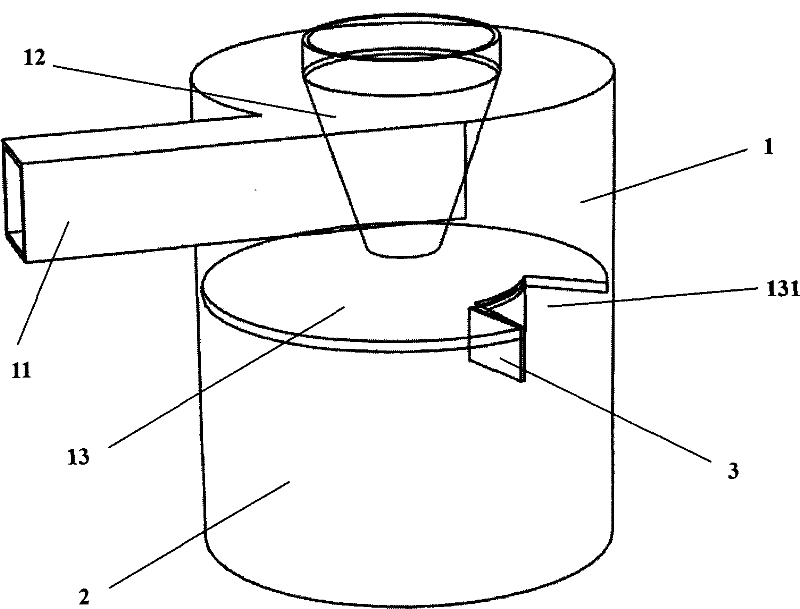

[0020] refer to figure 2 As shown, the dust discharge outlet of the cyclone separator of the vacuum cleaner of the present invention is arranged on the dust collection partition 13 between the cyclone separator 1 and the dust collection tank 2; the improvement is that the dust discharge of the dust collection partition 13 A guide vane 3 is provided on the edge of the outlet 131 , and the guide vane 3 is a piece extending into the dust collecting tank 2 along the edge of the dust outlet 131 .

[0021] refer to figure 2 As shown, the dust outlet of the cyclone separator of the vacuum cleaner of the present invention, wherein the deflector 3 is a sheet extending into the dust collecting tank 2 along the edge of the dust outlet 131; the part of the edge of the dust outlet 131 is the direction of dust and air flow The edges of the back and sides of the guide vane 3 section guide lines are the same as the dust discharge port 131 cross-sectional edge profile; the guide vane 3 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com