Method and device for low-pressure treatment of coalbed methane

A coal-bed methane and low-pressure technology, which is applied in the field of devices for realizing the method, can solve the problems of reduced refrigeration efficiency, difficult operation, and prone to explosion, and achieve the effects of reducing emissions, reducing the greenhouse effect, and avoiding explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

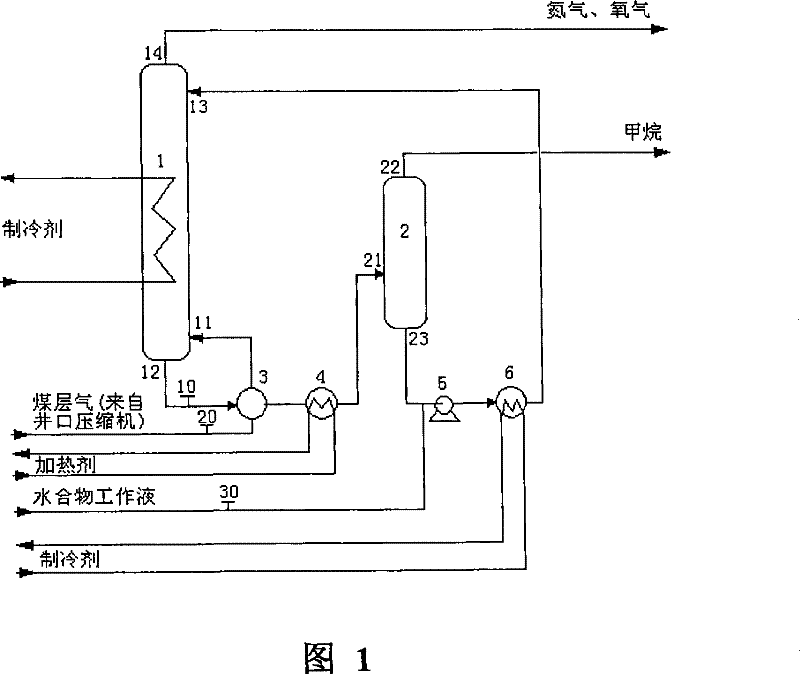

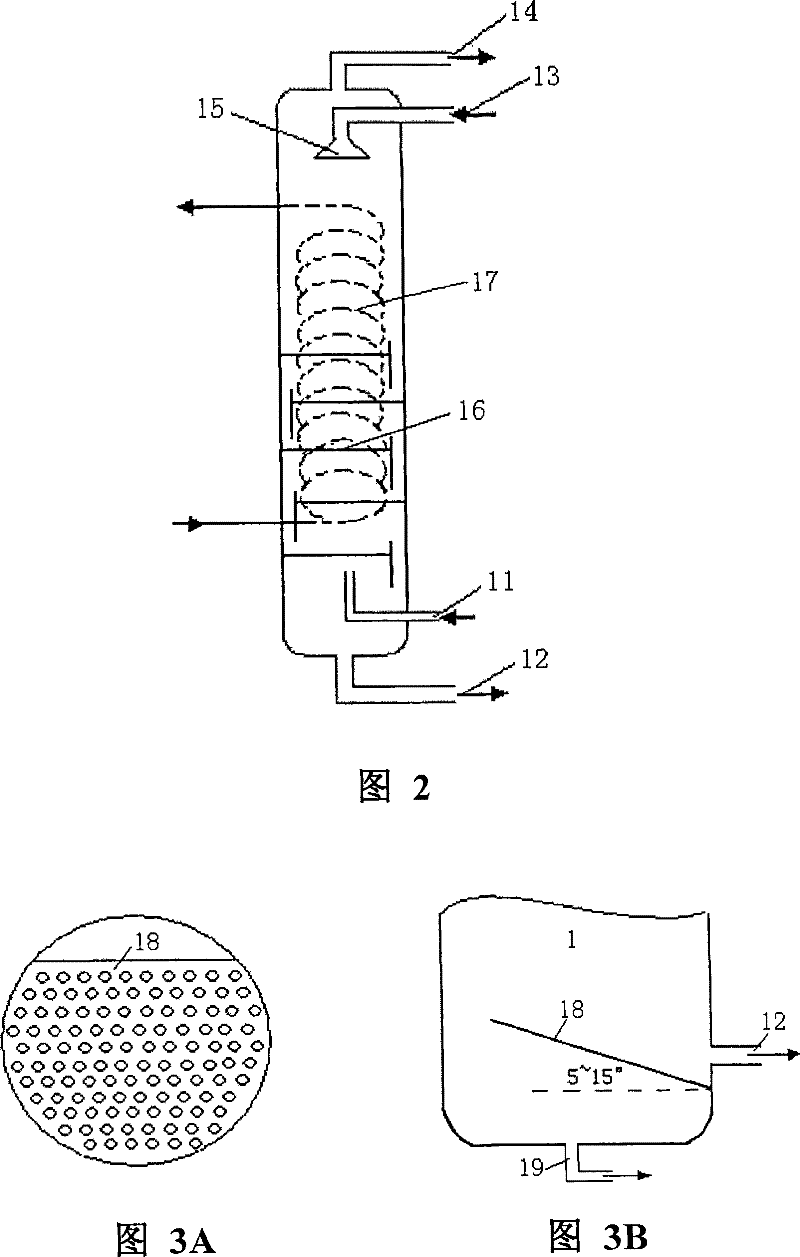

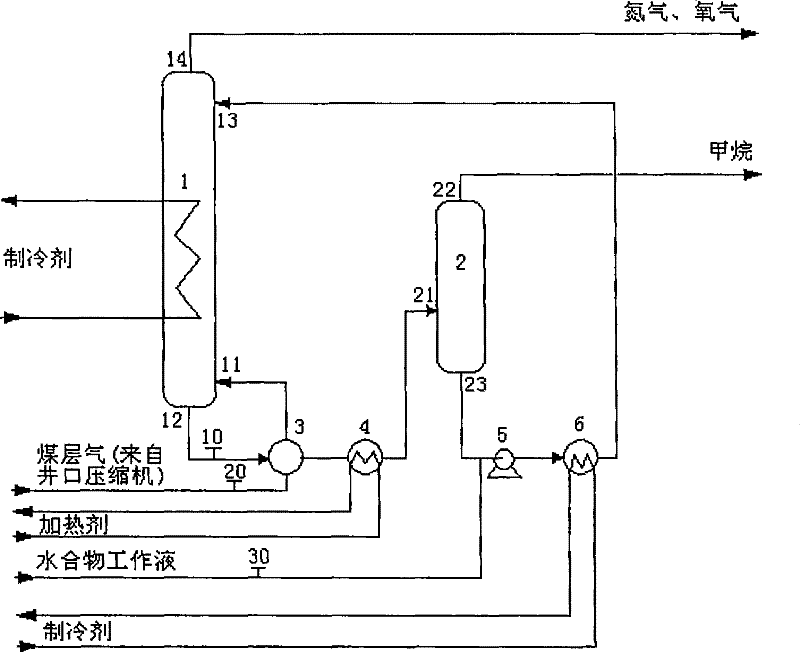

[0050] use figure 1 The preferred process flow shown (wherein hydration reactor 1 adopts figure 2 The combination structure of spray and sieve plate is shown, and set as Figure 3A and Figure 3B The shown filter plate 18) is used to purify the simulated coal bed gas to remove methane therein. Wherein, the composition of the raw material gas (equivalent to coalbed methane) entering the hydration reactor 1 is: N 2 (55.84mol%)+O 2 (14.87mol%)+CH 4 (29.29mol%); the operating temperature of the hydration reactor 1 is 3.0°C, and the operating pressure is 0.11MPa; the hydrate working fluid is an emulsion obtained by mixing the oil phase solution and the water phase solution according to the volume ratio of 4:1, and the oil phase solution is Commercially available No. 20 diesel oil, the aqueous phase solution is an aqueous solution containing tetrahydrofuran (wherein the molar fraction of THF is 0.06), and the aqueous phase solution contains Span-60 with a molar fraction of 0.0...

Embodiment 2

[0052] use figure 1 The preferred process flow shown (wherein hydration reactor 1 adopts figure 2 The combination structure of spray and sieve plate is shown, and set as Figure 3A and Figure 3B The shown filter plate 18) is used to purify the simulated coal bed gas to remove methane therein. Wherein, the feed gas (equivalent to oxygen-containing coalbed methane) entering the hydration reactor 1 consists of: N 2 (49.26mol%)+CH 4 (29.63mol%)+O 2 (21.11mol%); the operating temperature of the hydration reactor is 3.5°C, and the operating pressure is 0.30MPa; the hydrate working fluid is an emulsion obtained by mixing the oil phase solution and the water phase solution according to the volume ratio of 4:1, and the oil phase solution is commercially available Selling No. 20 diesel oil, the aqueous phase solution is an aqueous solution containing tetrahydrofuran (wherein the molar fraction of THF is 0.06), and the aqueous phase solution contains Span-60 with a molar fraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com