Chuck structure

A chuck and tool technology, which is applied in the field of chuck structure for clamping drilling tools, can solve the problems of high manufacturing cost, complex chuck structure, slippage of the gripper and tool, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

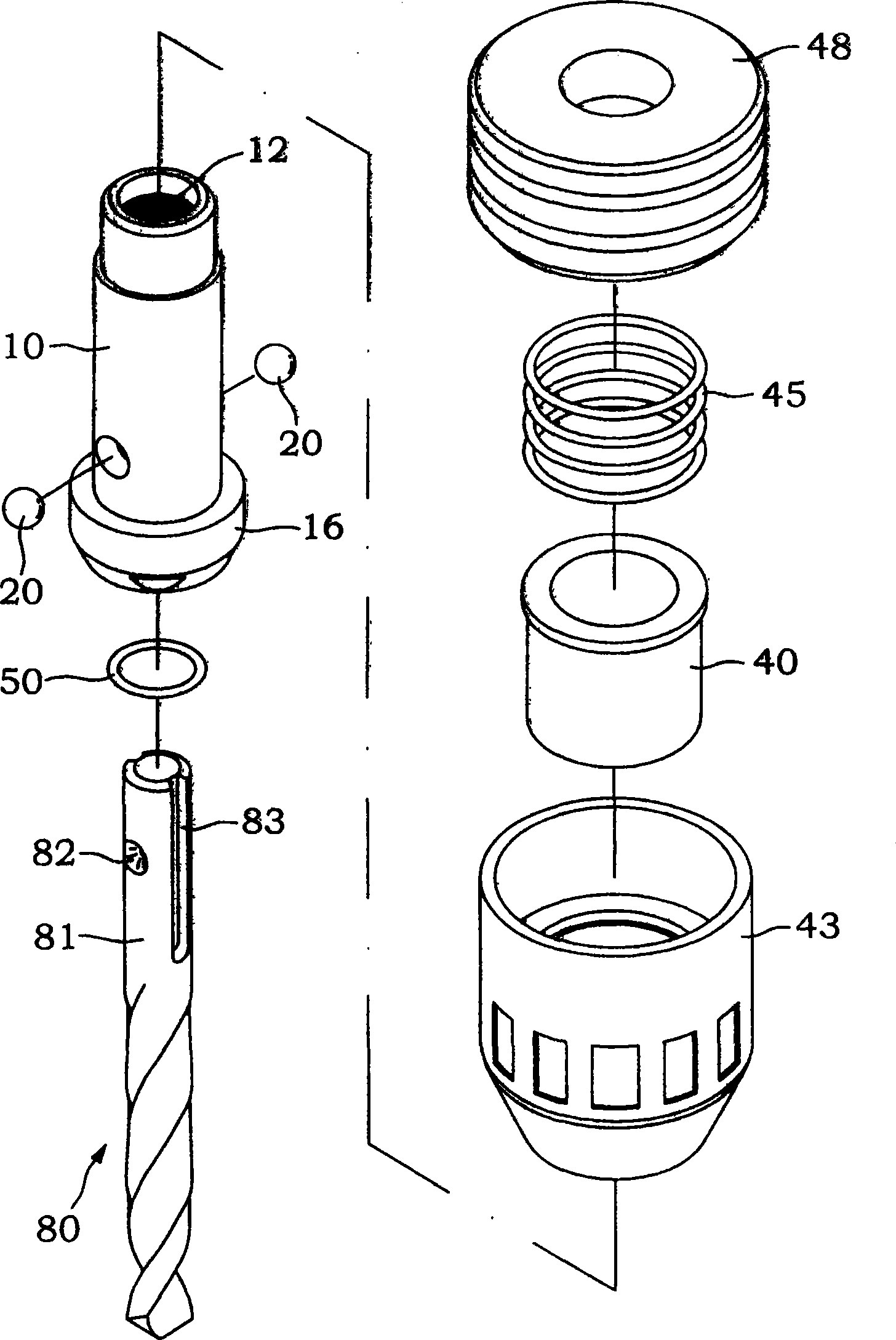

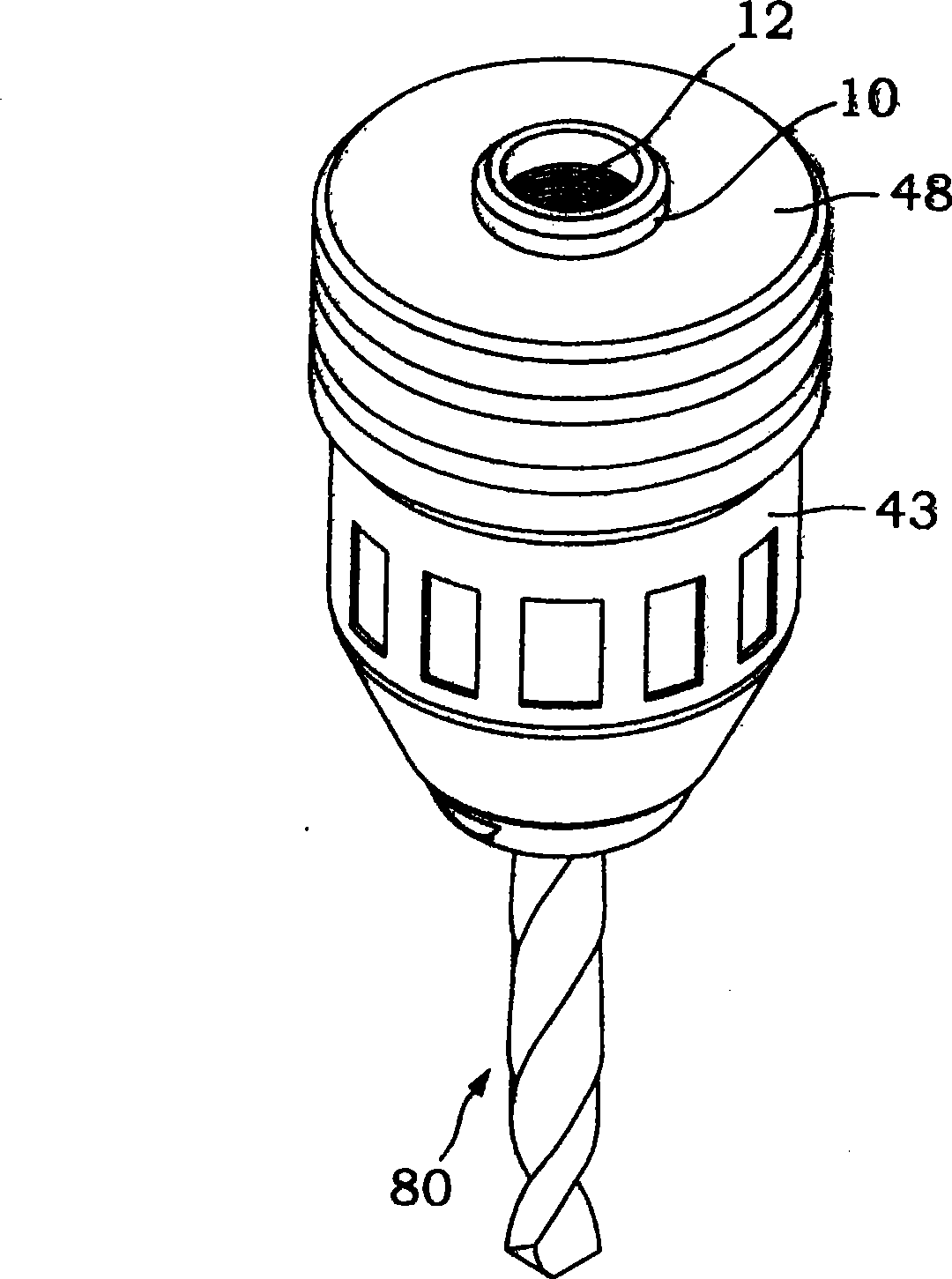

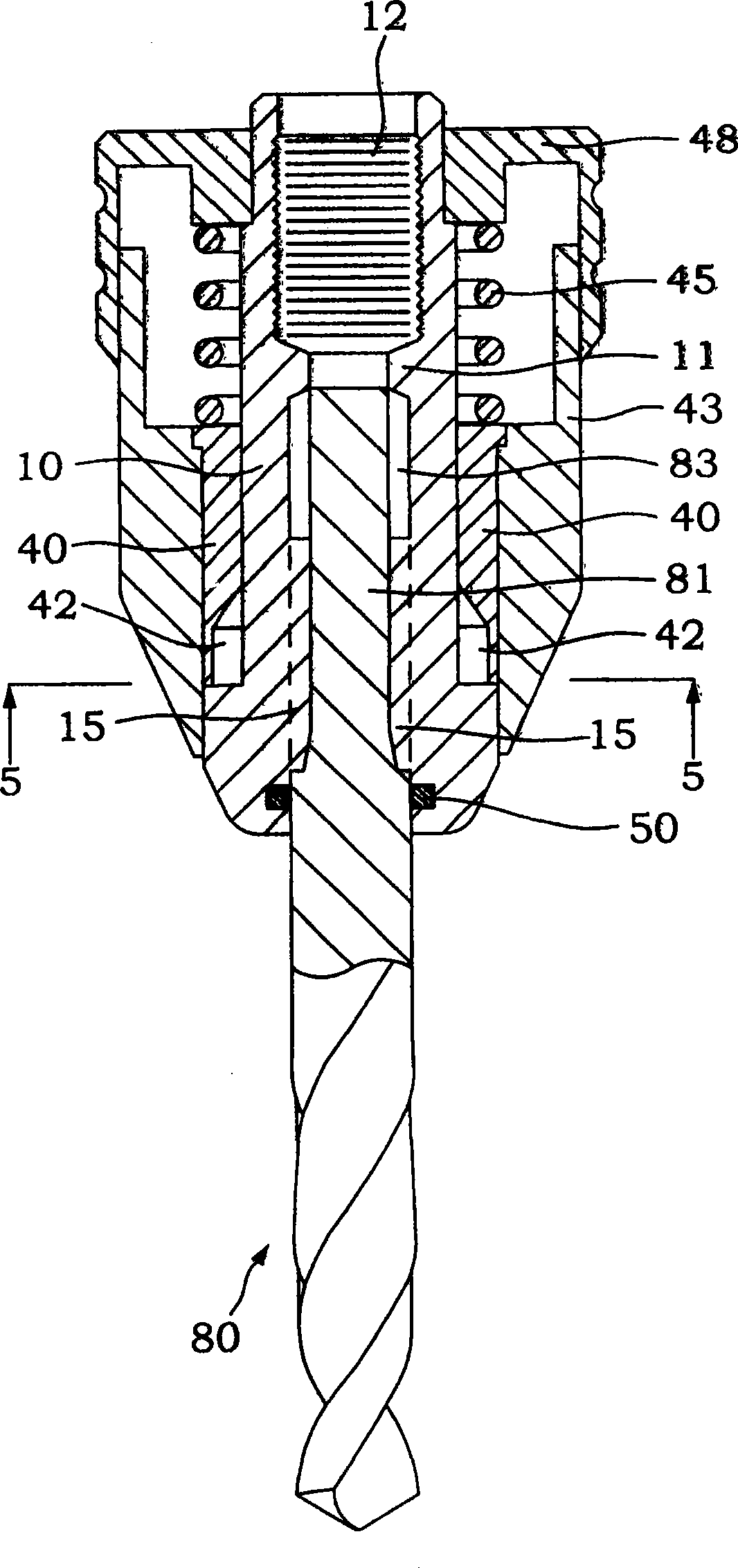

[0028] One body 10, such as figure 1 , figure 2 , Figure 4A , the center of which is penetrated by a shaft hole, and a flange 11 is formed on the inner wall of the hole, so that the shaft hole is divided into upper and lower sections. The power shaft (not shown) is connected, the lower part is a tool piercing hole 13, which can be used for the positioning part 81 of a knife 80 to pass through; the knife piercing hole 13 is provided with a stop ring near the lower open end hole 50, to prevent drilling chips or dust from penetrating into the body 10 when the tool 80 is working;

[0029] A tool axial positioning structure, such as figure 1 , figure 2 , Figure 4A , at least one element 20 that can reciprocate radially along the wall surface is arranged on the wall surface of the tool piercing hole 13 . And the part of the element 20 protrudes out of the tool piercing hole 13 when it moves radially inward to the extreme position; in the embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com