Welding gun adjusting seat

A technology for adjusting the seat and the welding gun, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of the orientation and angle limitation of the welding gun adjustment, affecting the welding quality, and poor adjustment accuracy of the welding gun adjusting seat, etc. Multi-angle adjustment, the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

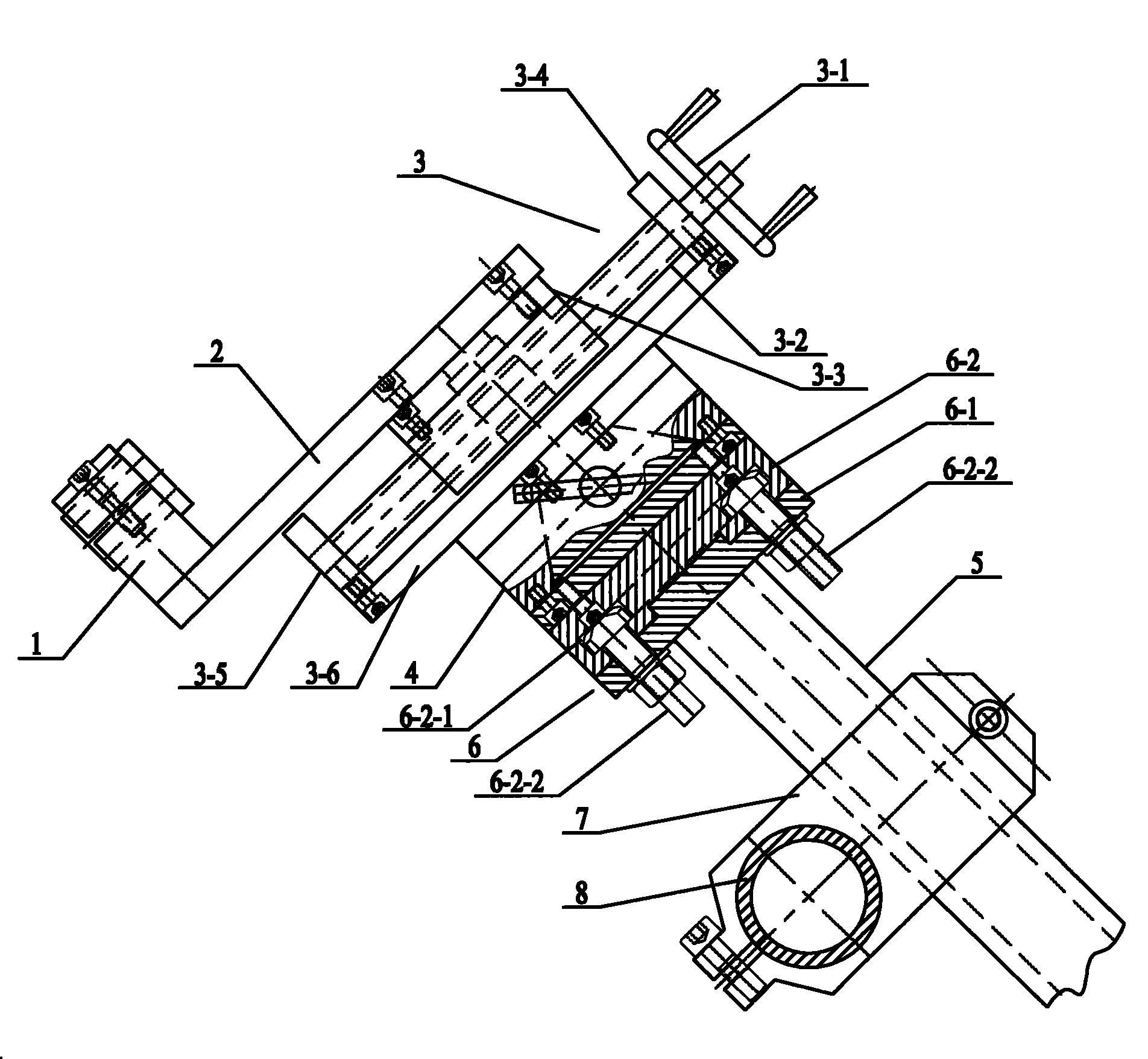

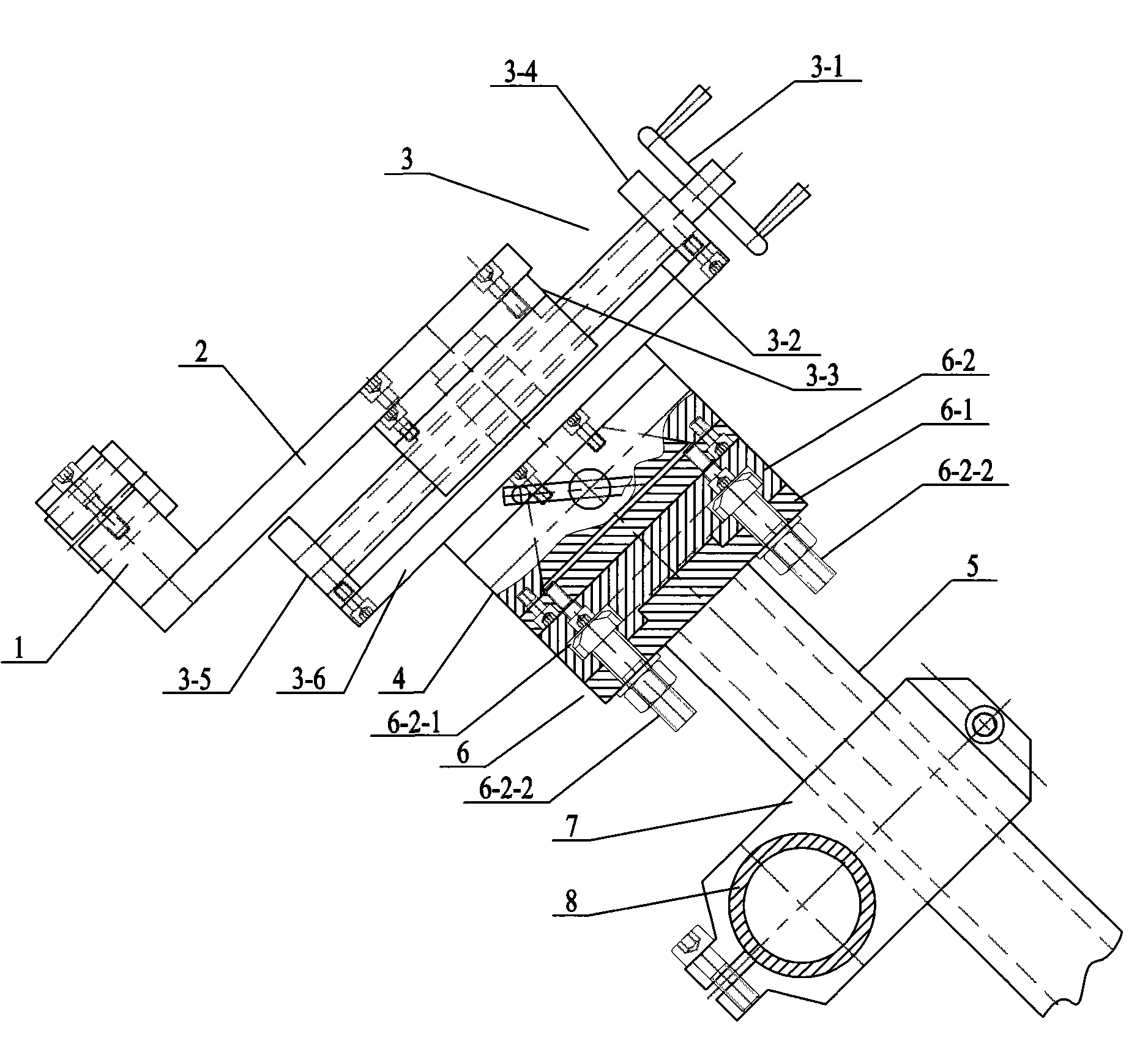

[0009] The welding torch adjustment seat in this embodiment includes a welding torch fixing seat 1 , a connecting plate 2 , a first adjustment device 3 , a second adjustment device 4 and an adjustment rod 5 .

[0010] The first adjusting device 3 includes a handle 3-1, a lead screw 3-2, an adjusting nut 3-3, a bearing seat 3-4, a bearing seat B 3-5 and a supporting plate 3-6. Above-mentioned first bearing seat 3-4 and second bearing seat 3-5 are connected on the upper side of supporting plate 3-6, and first bearing seat 3-4 and second bearing seat 3-5 are relatively arranged. Leading screw 3-2 and the bearing that is arranged in above-mentioned two bearing blocks are mutually matched and connected, thereby A bearing seat 3-4 and B bearing seat 3-5 support leading screw 3-2. The adjusting nut 3-3 is arranged between the above two bearings, and is threaded on the leading screw 3-2. The handle 3-1 is connected to one end of the leading screw 3-2. The connecting plate 2 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap