Washing machine

A washing machine and washing technology, applied in the field of washing machines, can solve problems such as water flow diffusion, cloth damage, and obstruction of water discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

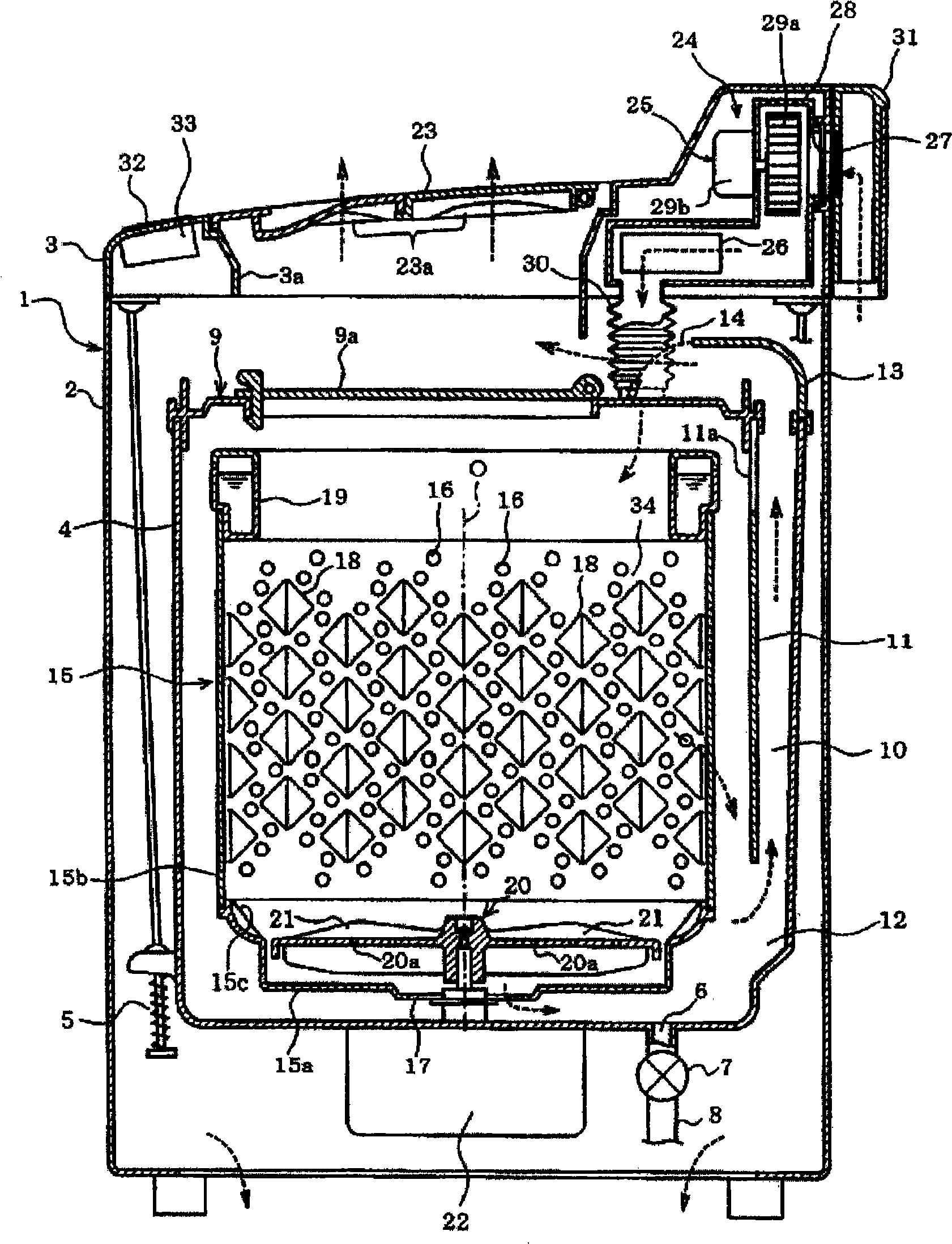

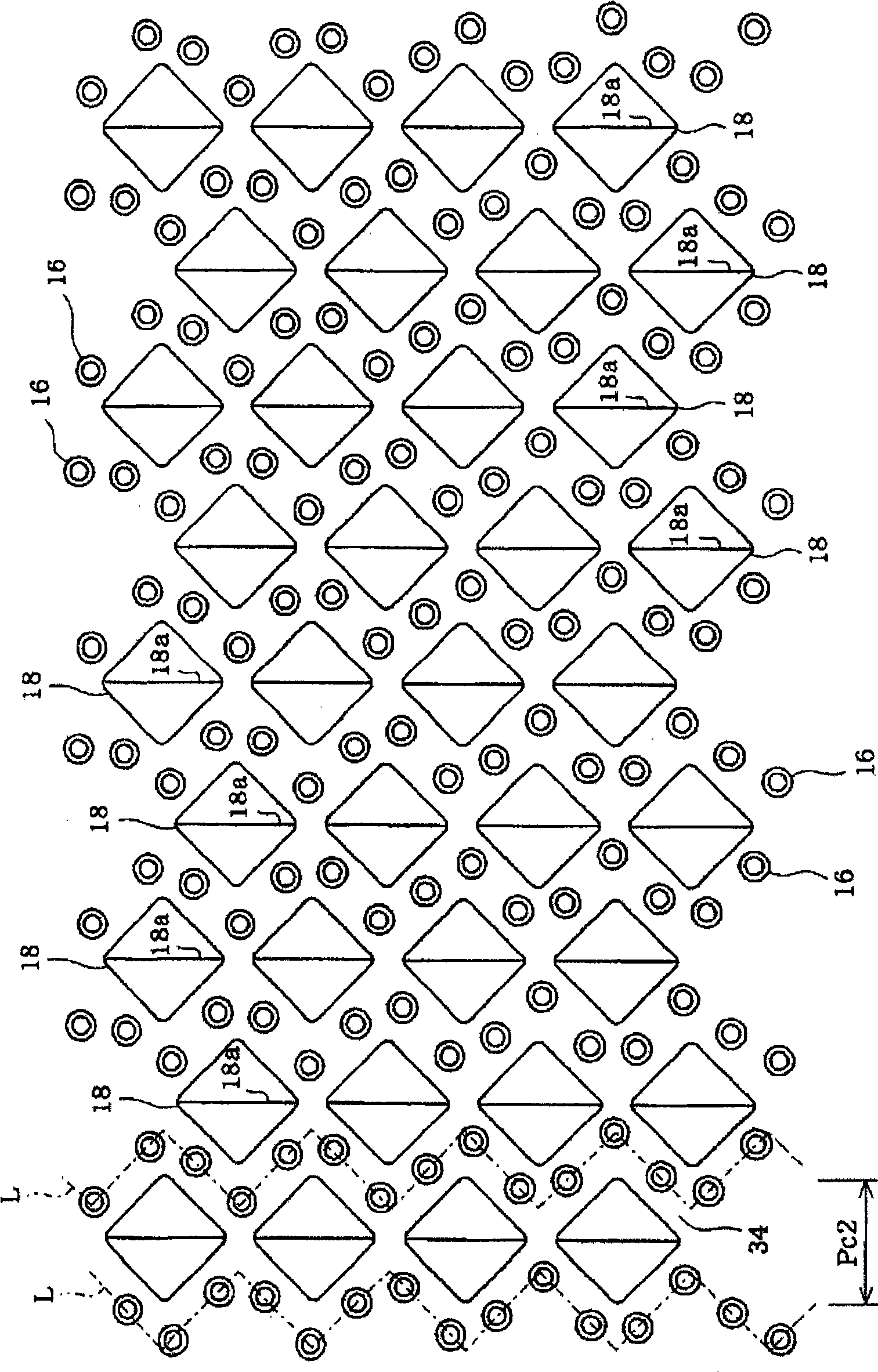

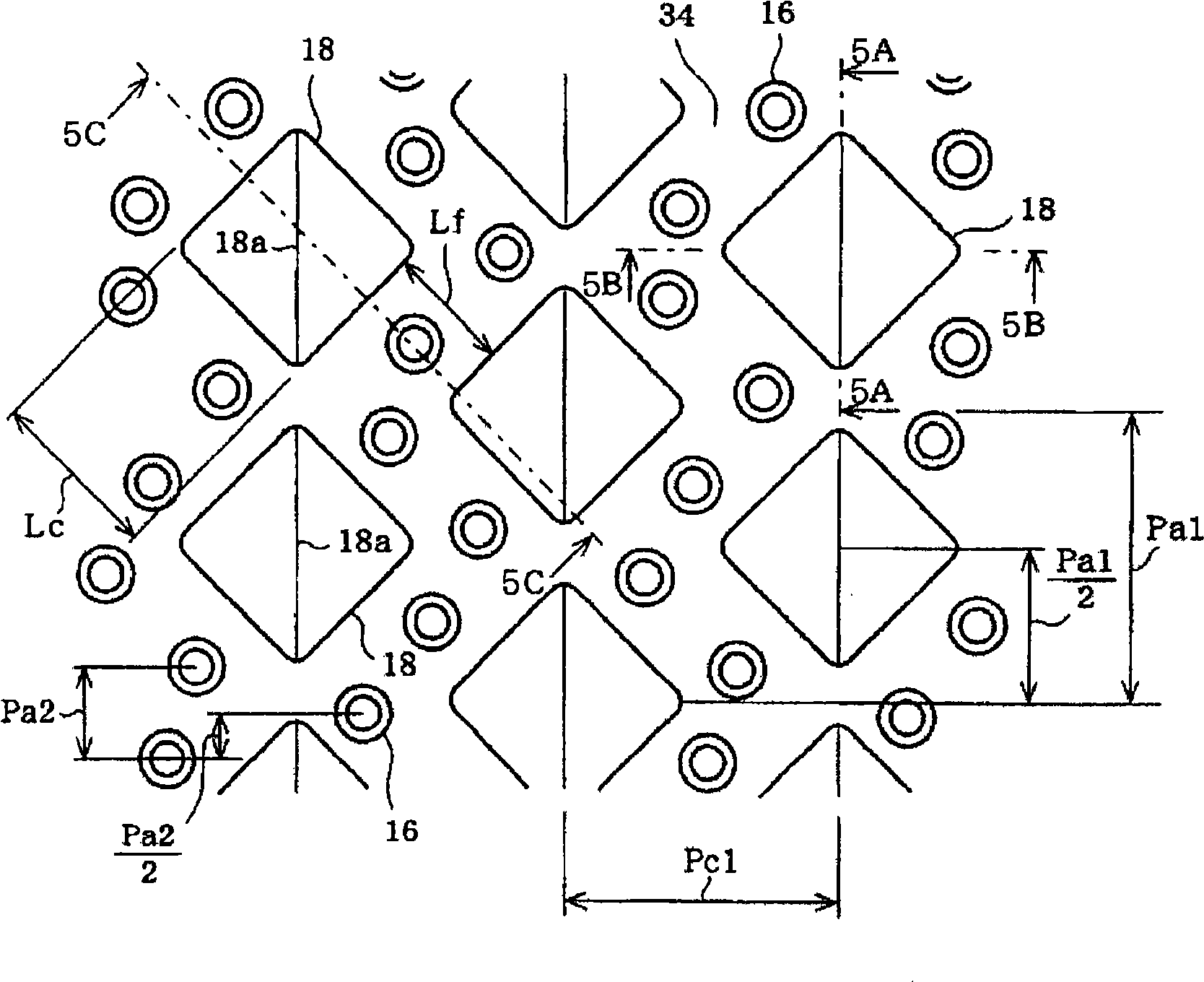

[0035] Below, refer to Figure 1 ~ Figure 5C , the first embodiment of applying the present invention to a washing machine with a drying function including a washing and dehydrating tank rotating around a vertical axis will be described. figure 1 It is a longitudinal sectional view showing the overall structure of the washing machine. The main body 1 forming the outer contour of the detergent includes a rectangular box-shaped outer case 2 and a top cover 3 covering the top. Both the upper and lower sides of the outer box 2 are open, and in the outer box 2, a bottomed cylindrical water tank 4 with an upper opening is provided via an elastic support mechanism 5 .

[0036] The water tank 4 is non-porous and capable of storing water, and a drain pipe 8 is connected to a drain port 6 at the bottom of the water tank 4 via a drain valve 7 . Further, the upper surface of the water tank 4 is airtightly covered with a disk-shaped tank cover 9 that closes the opening. In the substanti...

no. 2 Embodiment

[0078] Figure 9 ~ Figure 14 A second embodiment in which the present invention is applied to a drum-type washing machine with a drying function is shown. in, Figure 9 It is a longitudinal sectional side view showing the schematic structure of the whole washing machine. First, refer to the Figure 9 Describe the overall structure.

[0079] The box-shaped housing 51 forming the shell of the detergent is provided with an operation panel 53 on the upper part, and is provided with an opening in the left-right direction on the lower side, especially on the front panel 52 forming the front of the product among the members constituting the housing 51 . The closed door 54 is further below facing the handle 55a of the exhaust filter device 55 outside the front face, and is equipped with the cold wind blowing unit 56 (details are all described later) facing the outside in addition. Furthermore, a platen 57 constituting the bottom of the case 51 is provided so as to close the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com