Workshop scheduling method for Job-shop discrete production

A discrete, workshop technology that can be used in instruments and other directions to solve problems such as minimal optimization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

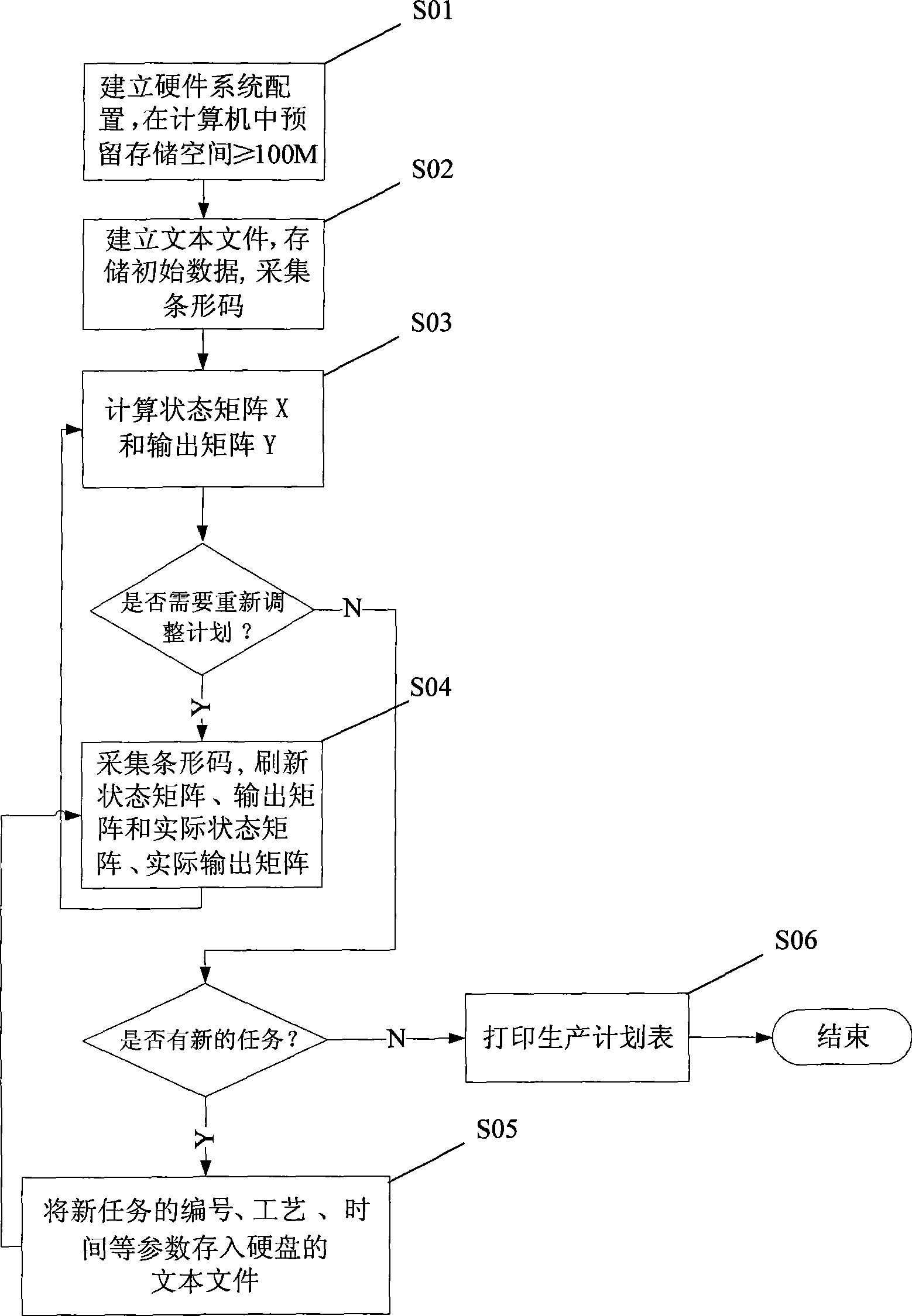

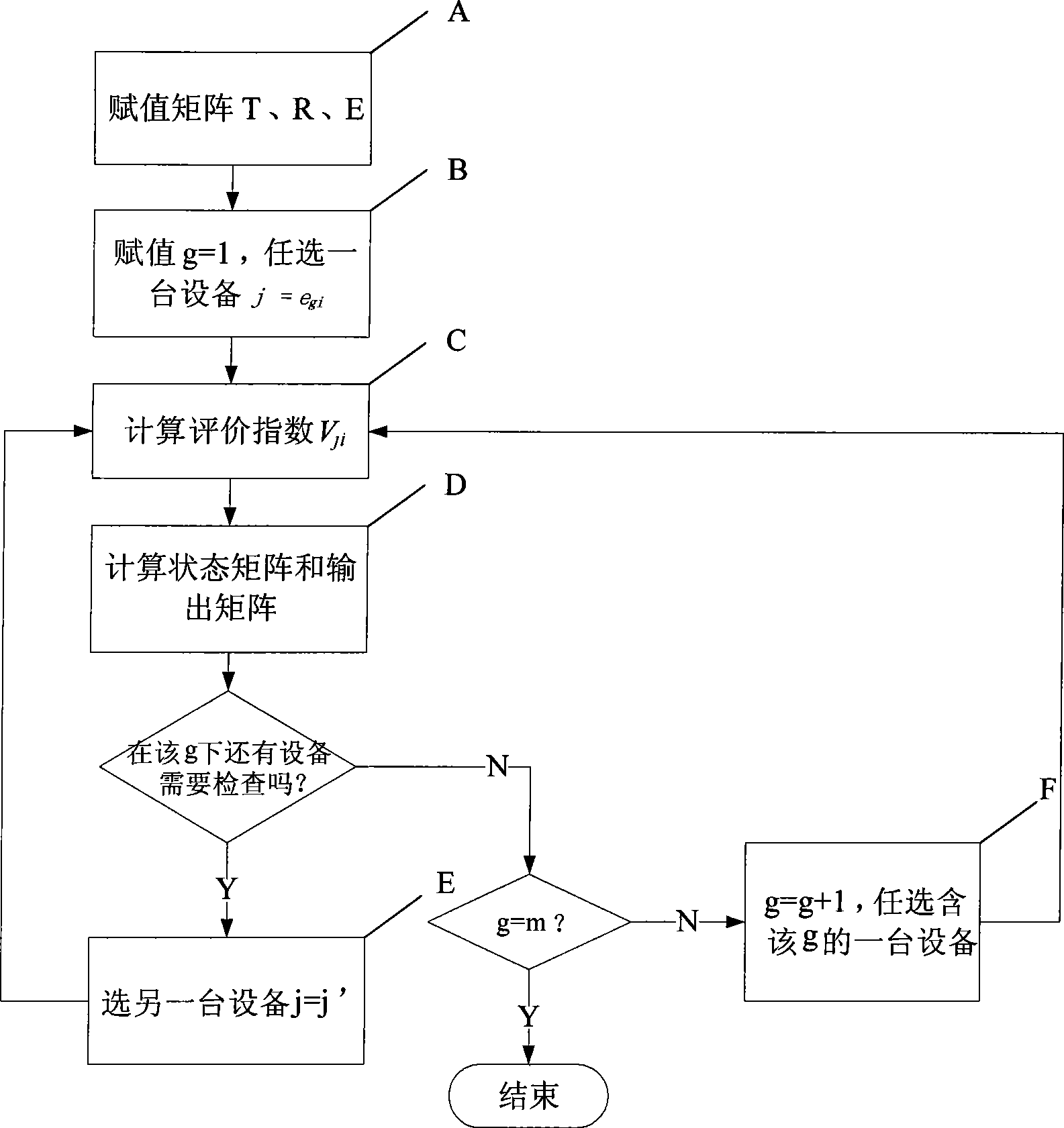

Method used

Image

Examples

Embodiment 1

[0143] Example 1: Scheduling of 4 devices and 5 tasks.

[0144] The objects of scheduling and scheduling are 4 devices and 5 tasks, and the scheduled delivery dates of the 5 tasks are the 35th, 40th, 45th, 35th, and 45th hours respectively. The processing route matrix R and the processing time matrix T (the unit is set to hours) are known, and the equipment sequence matrix E is obtained by inverting the processing route matrix R. as r 23 = 3 means that task 3 processed on equipment 2 is arranged in the order of 3 on the task processing route, then e 33 =2 indicates that task 3 with the order of processing route 3 is processed on equipment 2. t 12 =12 means that the time consumed by task 2 processed on equipment 1 is 12. The processing time starts from 0, and the delivery time of task 1 to task 5 is the 35th, 40th, 45th, 35th, and 45th hours in turn. The three matrices R, E, and T are:

[0145] R = ...

Embodiment 2

[0182] Example 2: Production scheduling of 5 devices and 7 tasks.

[0183] The objects of production scheduling and scheduling are 5 devices and 7 tasks, which are put into production at 0 o'clock, but each device must wait for the processing tasks to be completed before it can start to accept the processing of these 7 tasks. The release time of the devices is from device 1 to The equipment 5 is {0, 3, 1, 3, 2} respectively, the processing route matrix R and the processing time matrix T (the unit is set to hours) are known, and the equipment sequence matrix E is obtained by inverting the processing route matrix R.

[0184] The matrices R, E and T are respectively:

[0185] R = 5 1 4 5 3 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com