Ice coating removal equipment for high-tension transmission line

A high-voltage transmission line, ice coating technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of low efficiency, dangerous operation, harsh conditions, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

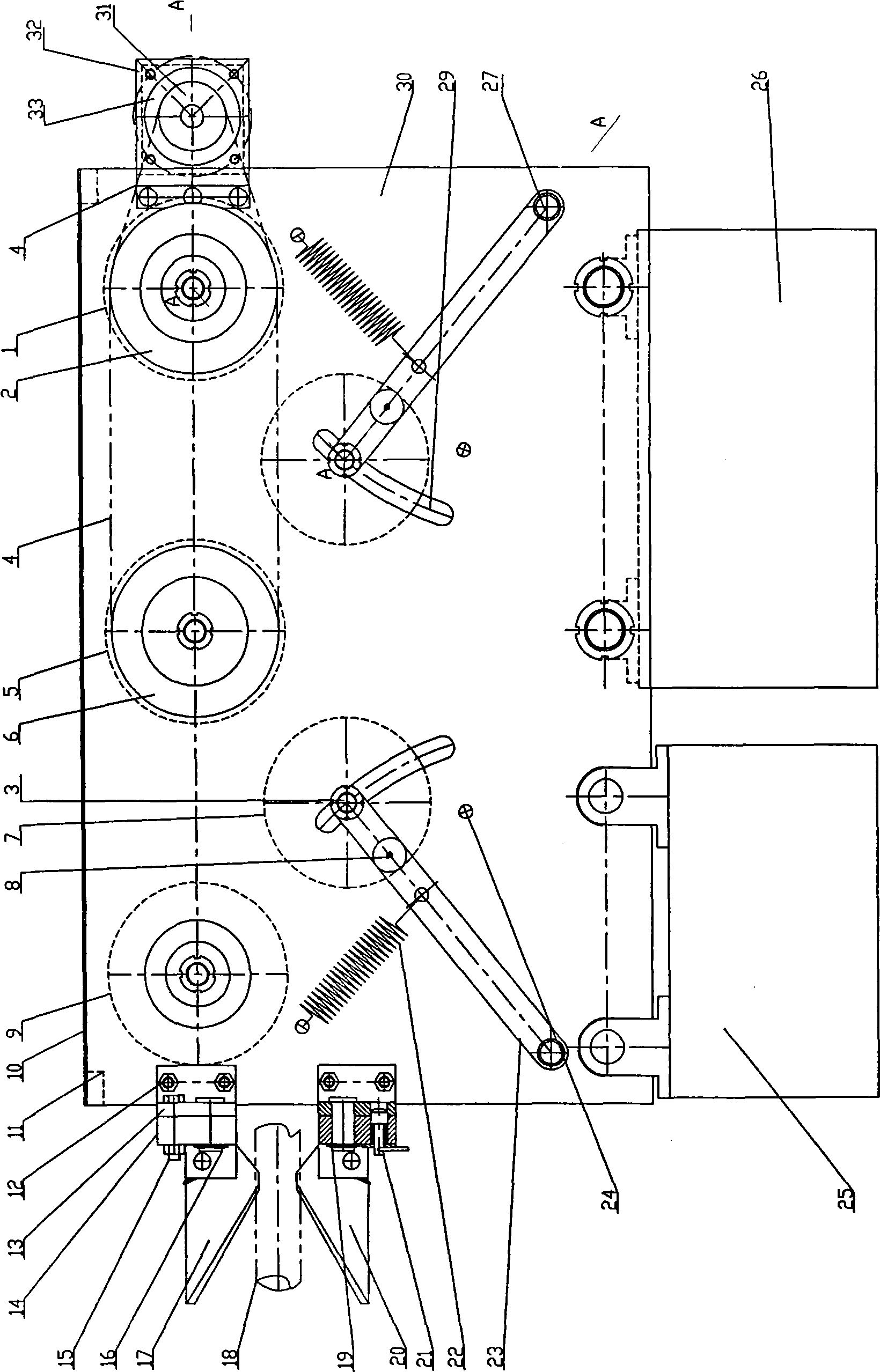

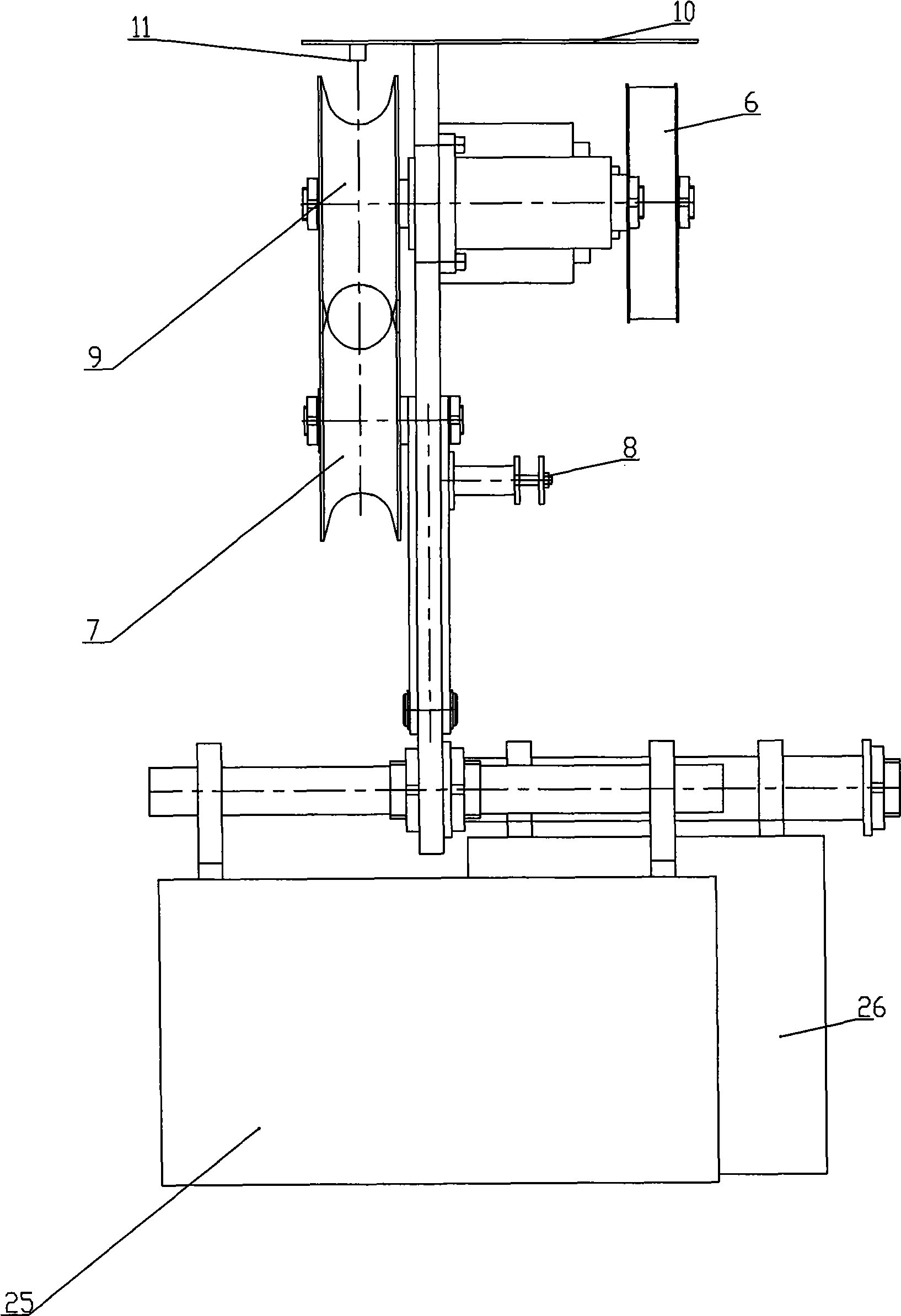

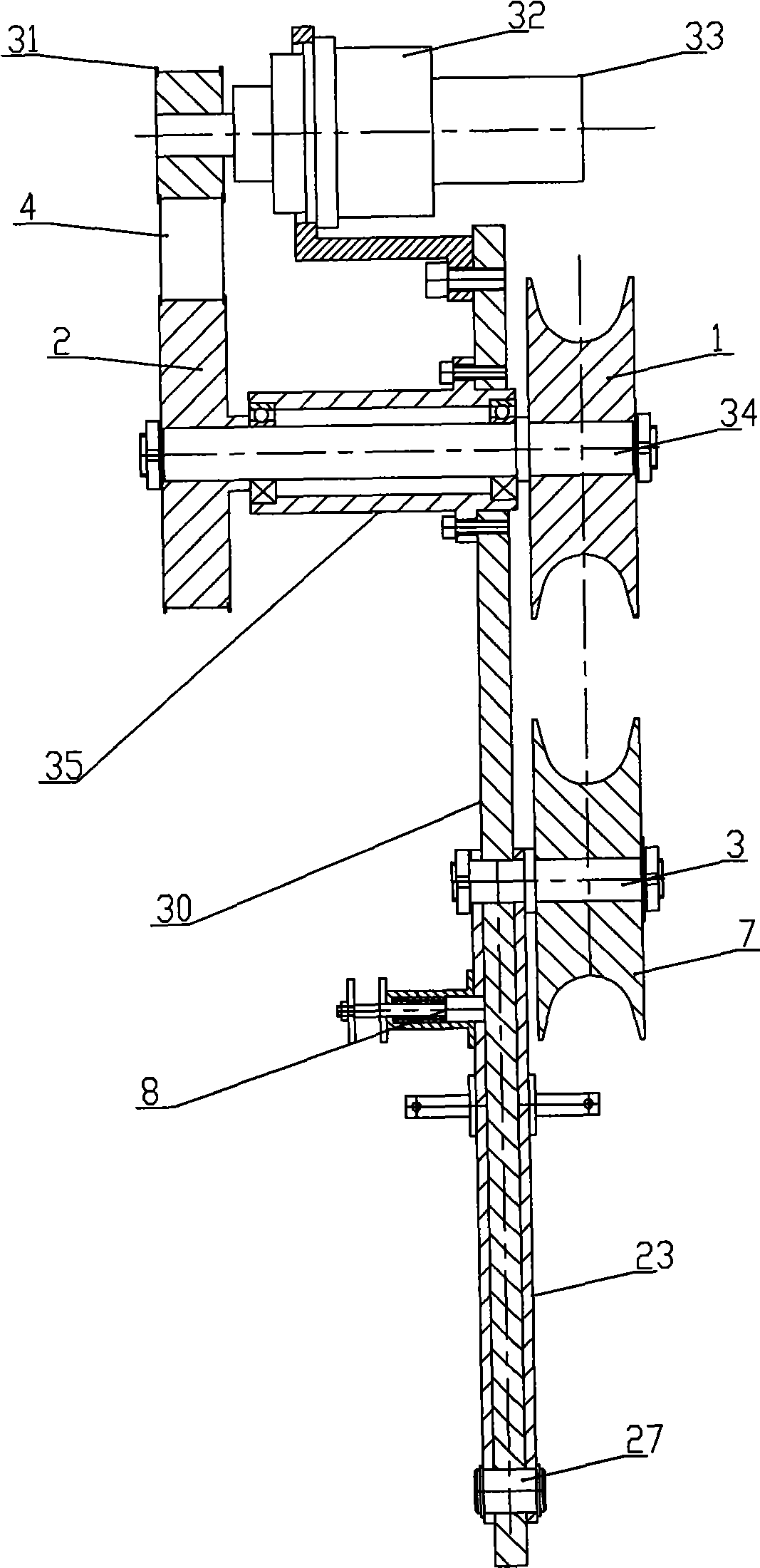

[0013] Such as figure 1 , 2 , 3, 4, 5, and 6, the high-voltage transmission line deicing equipment includes a frame 30, which is characterized in that: one side of the frame 30 is provided with a deicing knife mechanism, and the frame 30 Also be provided with traveling gear on, frame 30 bottoms are provided with electrical control box 25 and power supply storage battery 26.

[0014] The upper support 13 and the lower support 44 of the deicing knife mechanism are fixedly installed on the frame 30 by screws 12, and the upper knife rest base 14 is fixed on the upper support 13 by bolts 15 and bearing pins 16, and the upper knife rest 28 is installed on the upper knife rest base 14 by screw 42, and the upper cutter 17 is installed on the upper cutter rest 28 by the upper cutter rotary shaft 39, and the upper cutter 17 on the upper cutter rotary shaft 39 is provided with an axle sleeve 45 between two blades , both ends of the shaft sleeve 45 are provided with gaskets 41, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com