Control method for thermal valve

A thermal control valve and control method technology, applied in the direction of non-electric variable control, heating mode, temperature control, etc., can solve problems such as large current, achieve the effects of saving power consumption, simplifying noise countermeasures, and increasing valve opening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

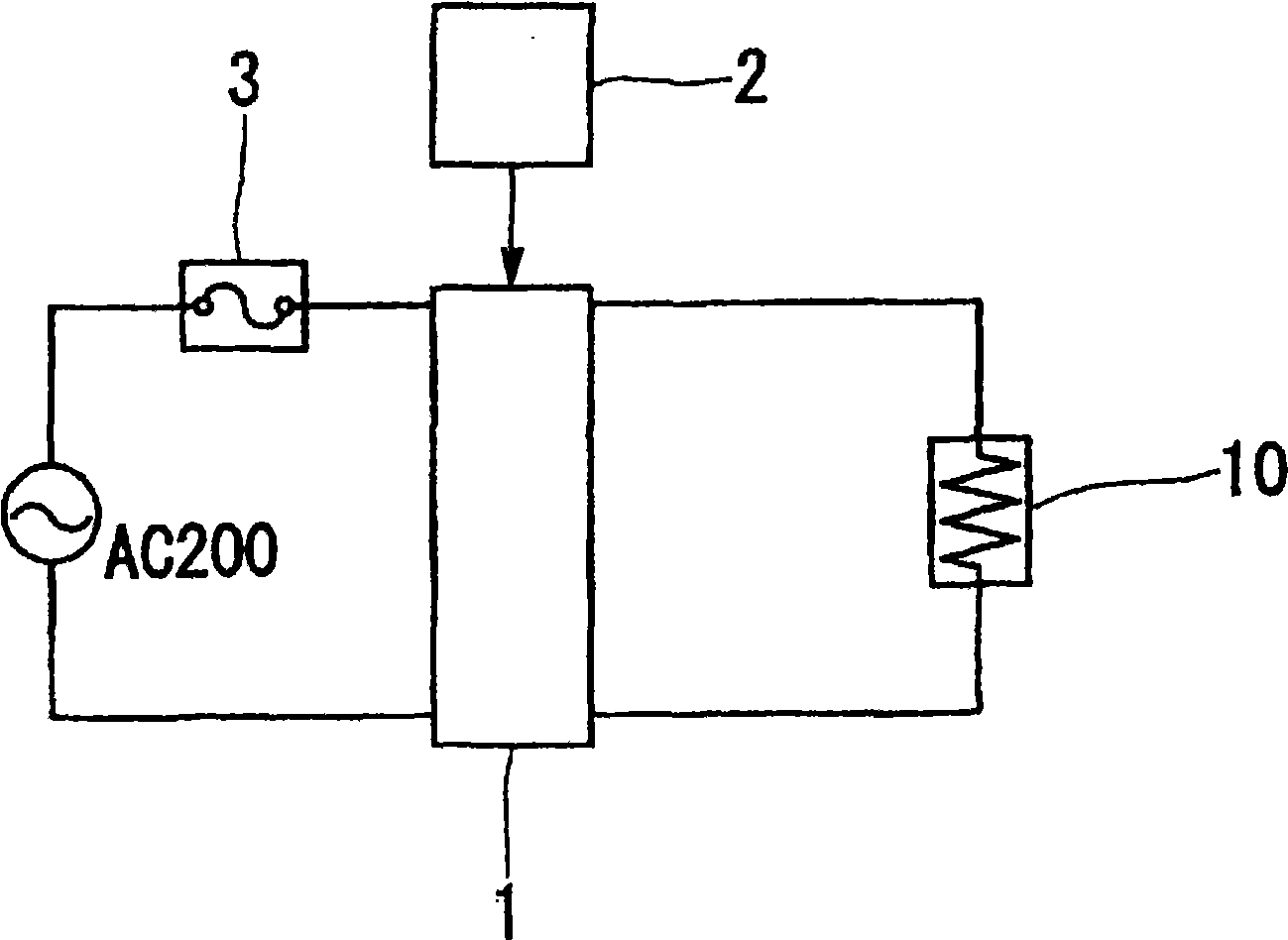

[0027] Hereinafter, regarding the control method of the thermal control valve of the present invention, specific embodiments thereof will be described in detail with reference to the drawings. figure 1 It is a circuit diagram showing an example of a control mechanism suitable for use in a control method of a thermal control valve. First, in figure 1 Among them, 10 represents the same thermal control valve as described above, and the thermal control valve has a PTC heater. 1 denotes a voltage regulator from which an output voltage is applied to the thermal control valve 10 . Also, 2 denotes a controller for controlling the output voltage of the voltage regulator 1 . In addition, 3 represents a fuse.

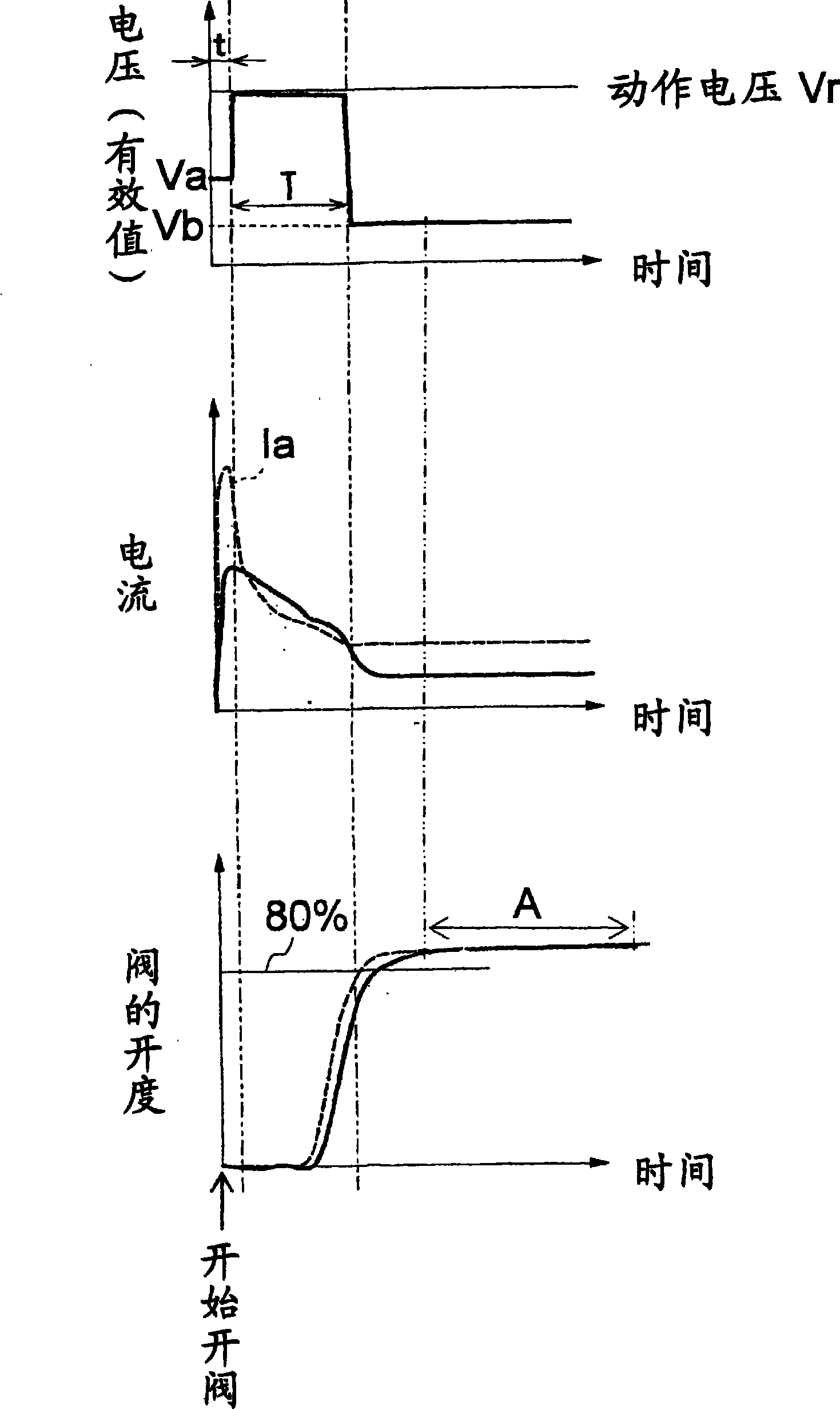

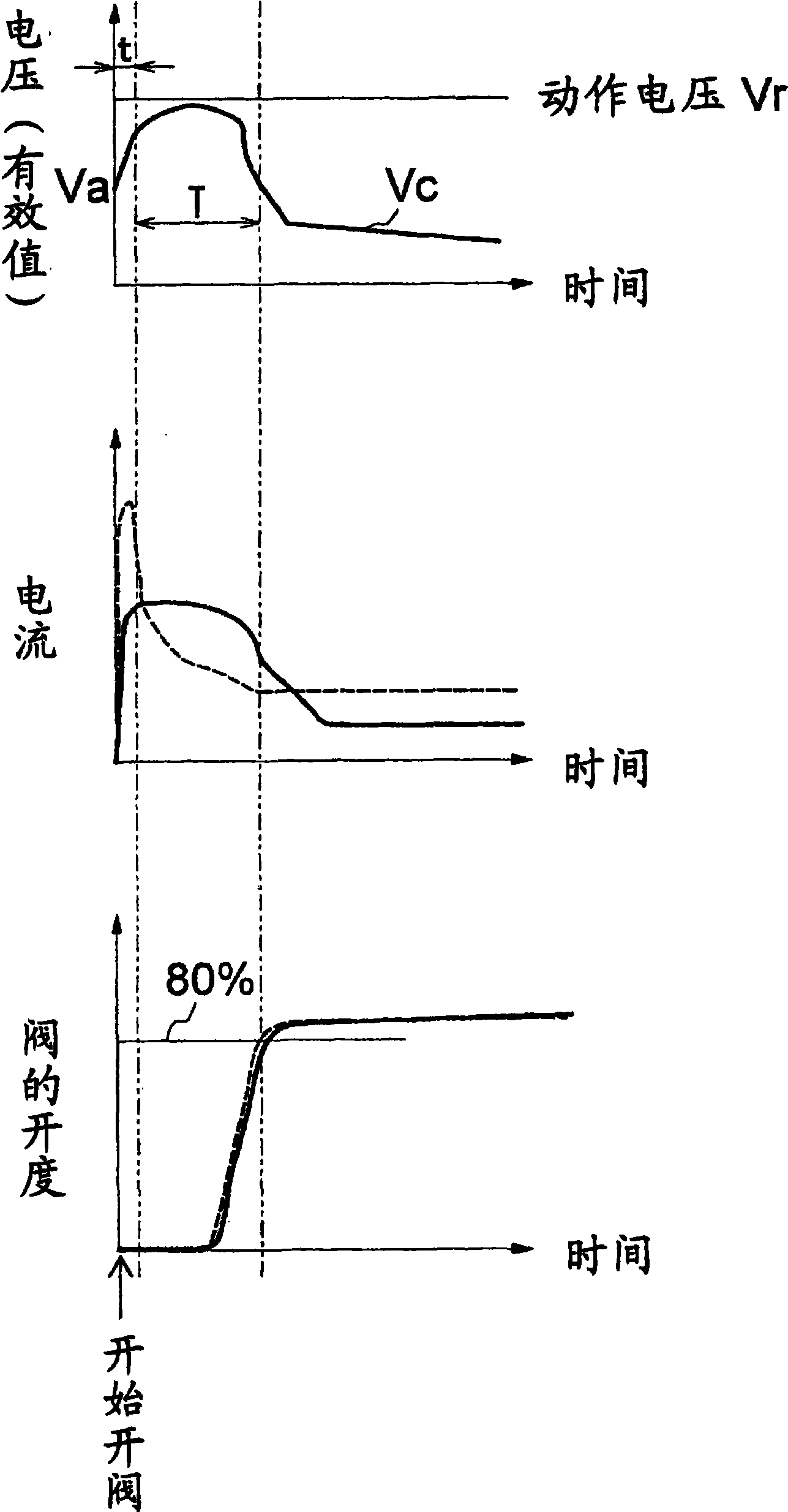

[0028] A first embodiment of a control method of a thermal control valve will be described. In this control method, as figure 2 As shown, first at the beginning (that is, when the valve starts to open), the voltage regulator 1 applies a voltage lower than the operating vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com