Dry-type soot purifying carriage for tamping coaling and coke discharge of coke oven

A technology for tamping coke ovens and purifying soot, which is used in coke ovens, soot removal, chemical instruments and methods, etc., can solve the problems of increased operating costs, huge equipment, and filter bag adhesion, and can reduce air leakage and resistance loss. , the effect of saving land and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

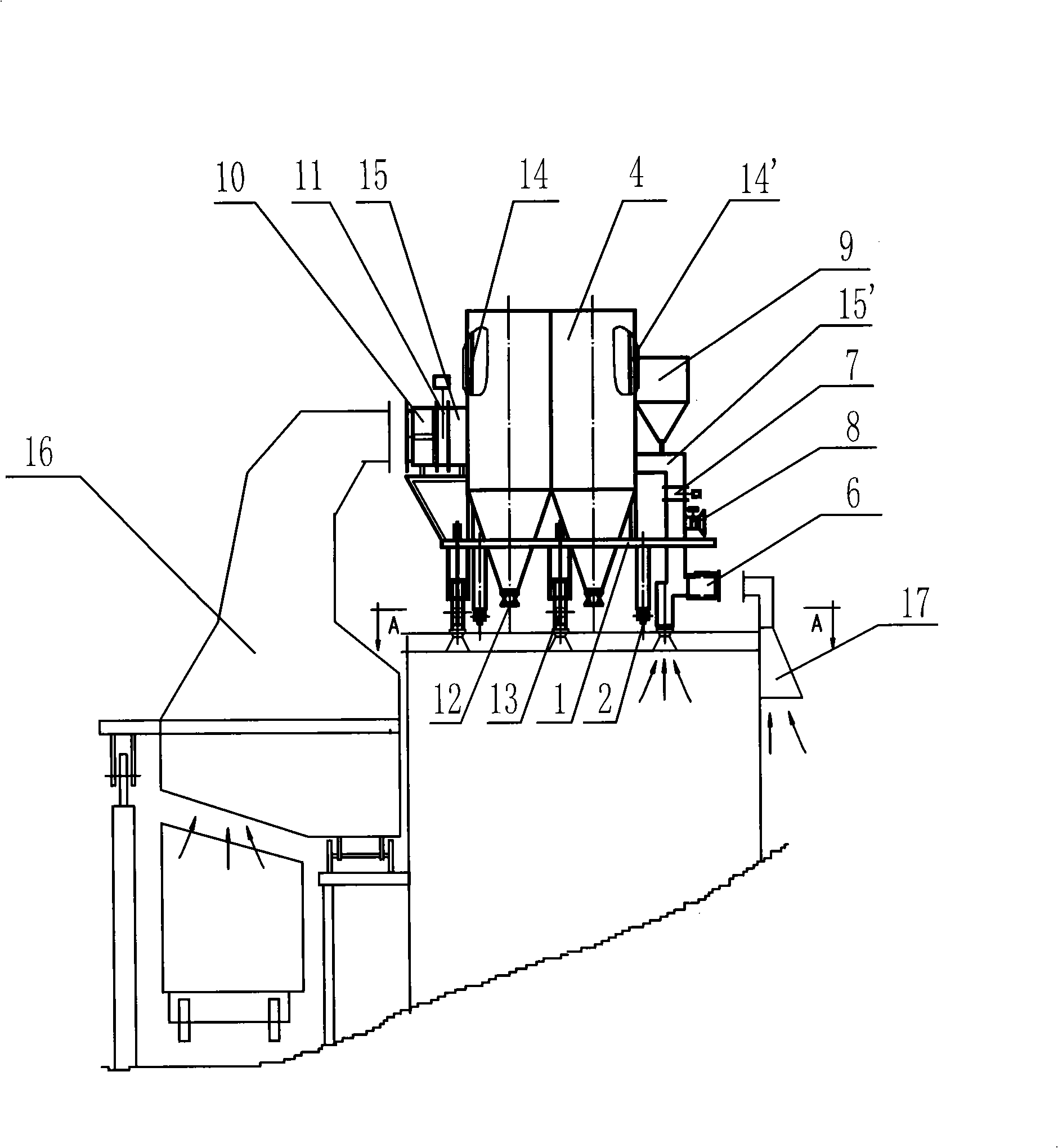

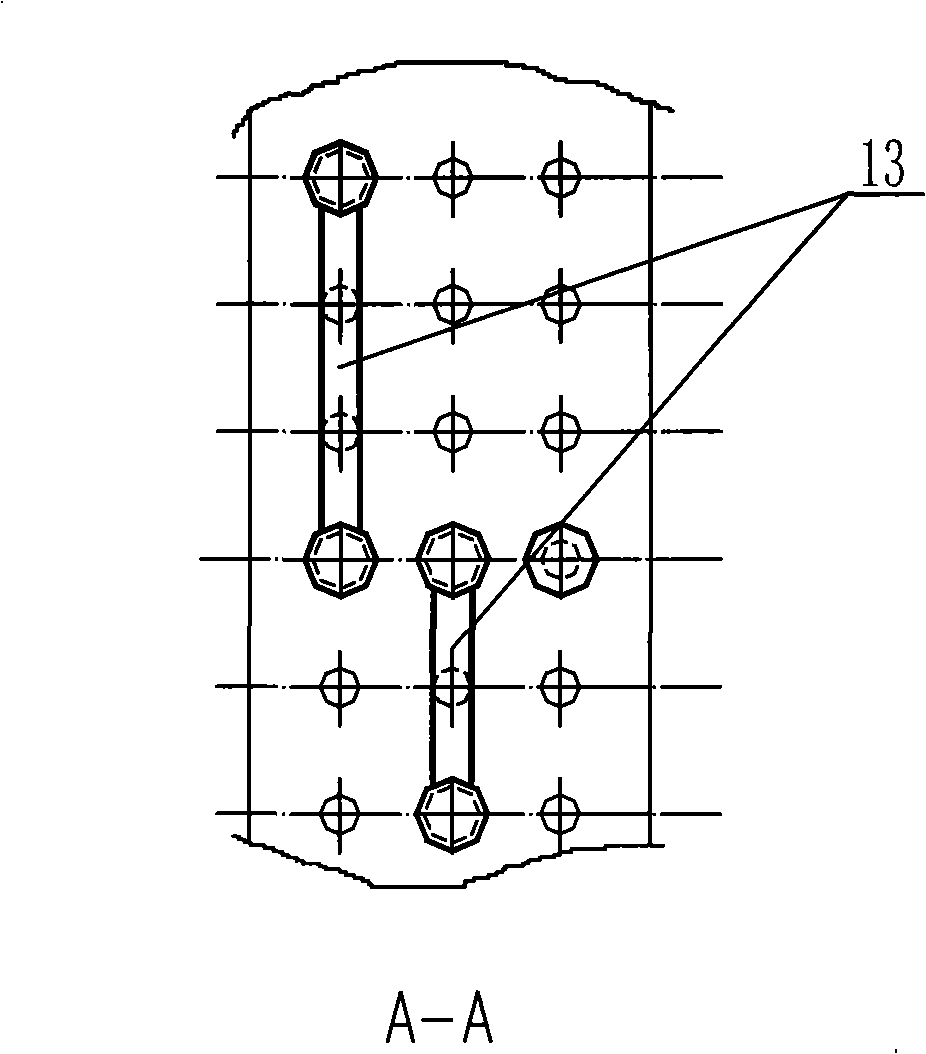

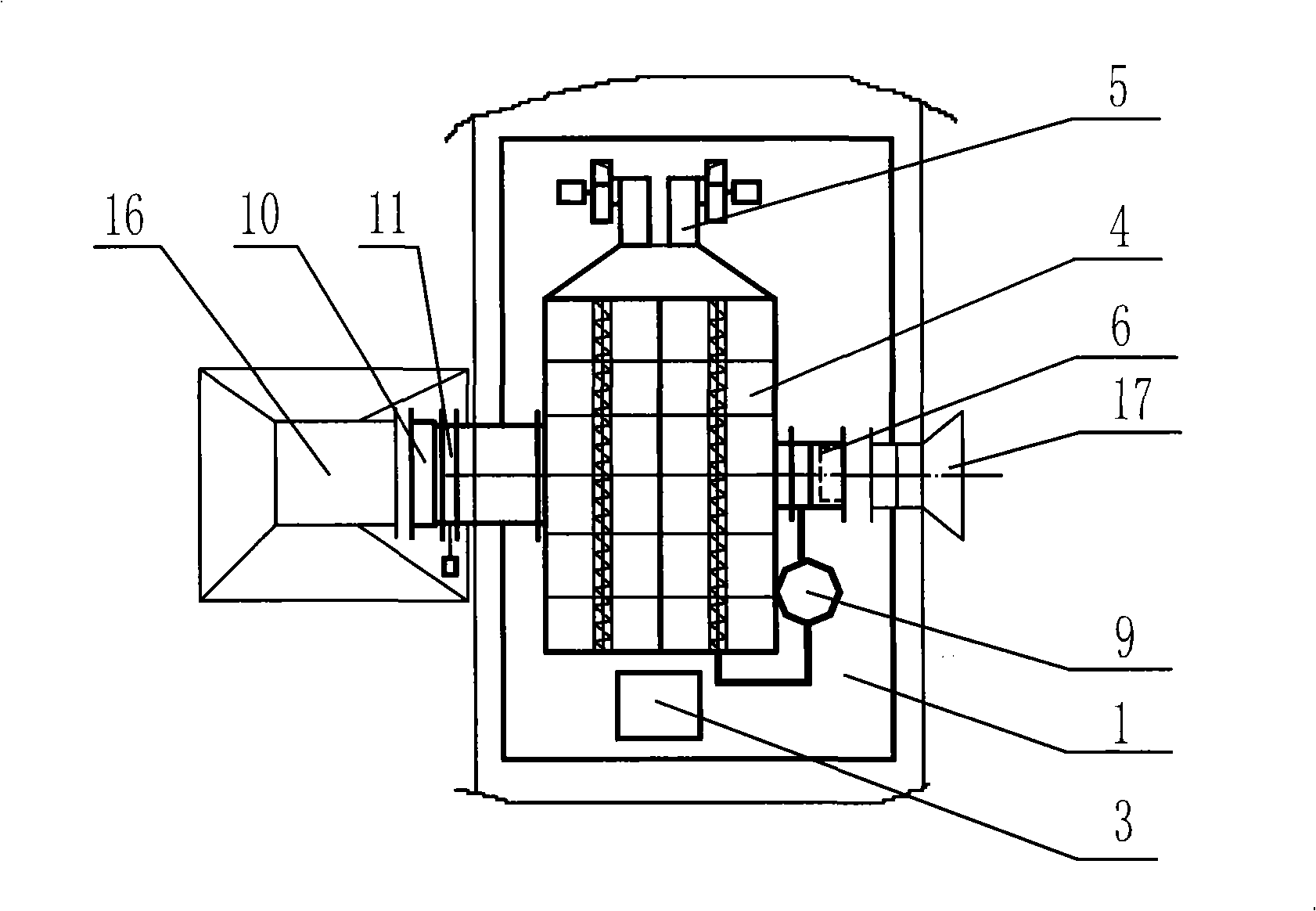

[0015] Describe below in conjunction with accompanying drawing the structure and technical content of tamping coke oven charging, coke-out dry type soot cleaning vehicle.

[0016] See figure 1 , figure 2 , image 3 , tamping coke oven coal charging, coke discharge dry-type smoke and dust purification vehicle, set on the roof of the coke oven, including car body 1, running device 2, electrical control system 3, dust collector 4, fan 5, coal charging flue gas introduction Device 6, coke discharge flue gas introduction device 10, U-shaped pipe smoke guide device 13, running device 2 is located at the lower part of the car body 1, and facilities such as an electrical control system 3, a dust collector 4, and a fan 5 are installed on the platform of the car body 1 .

[0017] In order to realize coke discharge and dust removal, a coke discharge flue gas introduction device 10 is provided. The coke discharge flue gas introduction device 10 uses a telescopic moving tube to dock wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap