Method for preparing polymer superhydrophobic surface by CaCO3 template method

A super-hydrophobic surface and polymer technology, which is applied in the field of preparing polymer super-hydrophobic surfaces, can solve the problems of difficulty in preparing large-area super-hydrophobic films, expensive raw materials or equipment, and limited practical applications, etc., to achieve easy large-area preparation, The effect of simple method and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

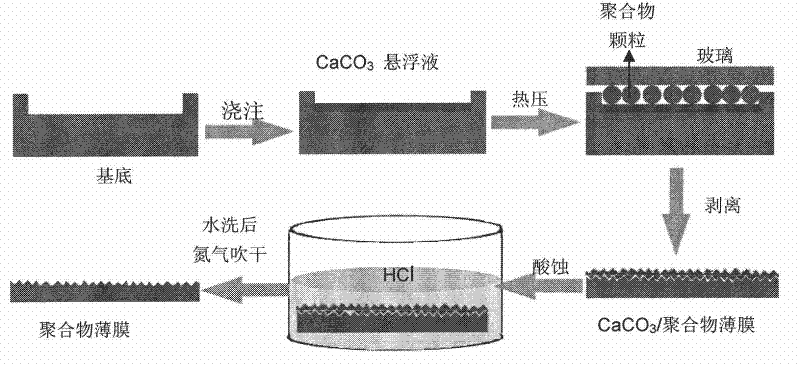

[0030] CaCO on glass substrate 3 Thin layer preparation: carve a frame with a size of 4cm*4cm on a polydimethylsiloxane (PDMS) sheet with a blade, and stick it on a clean hydrophilic glass sheet with double-sided adhesive. Then weigh 10g of CaCO 3 Granules (1500 mesh) were made into an aqueous suspension with a solid content of 10%. Take 5mL of the suspension and pour it on a glass slide, put it in an oven, bake it at 160°C for 5 minutes, and take it out to obtain a layer of CaCO on the surface. 3 Thin glass substrate.

[0031] Hot pressing LLDPE on the glass substrate: stack a layer of LLDPE particles (linear low-density polyethylene, Shanghai Secco Petrochemical Co., Ltd.) with a thickness of about 3mm on the prepared glass substrate, and put it together with another piece of clean glass Heat it in an oven at 200°C for 10 minutes, then cover the clean glass plate on the molten LLDPE, clamp it with two clamps, keep it in the oven for 10 minutes, take it out, and cool it to ...

Embodiment 2

[0034] CaCO on glass surface 3 Thin layer preparation is as in Example 1.

[0035] Hot pressing LDPE on the glass substrate: stack a layer of LDPE particles (low density polyethylene, Shanghai Petrochemical, N220) with a thickness of about 6mm on the glass substrate prepared above, and put it into a 200°C oven together with another clean glass plate Heat it in the middle for 10 minutes, then cover the clean glass plate on the LDPE, clamp it with two clamps, keep it in the oven for another 5 minutes, take it out, and cool it to shape.

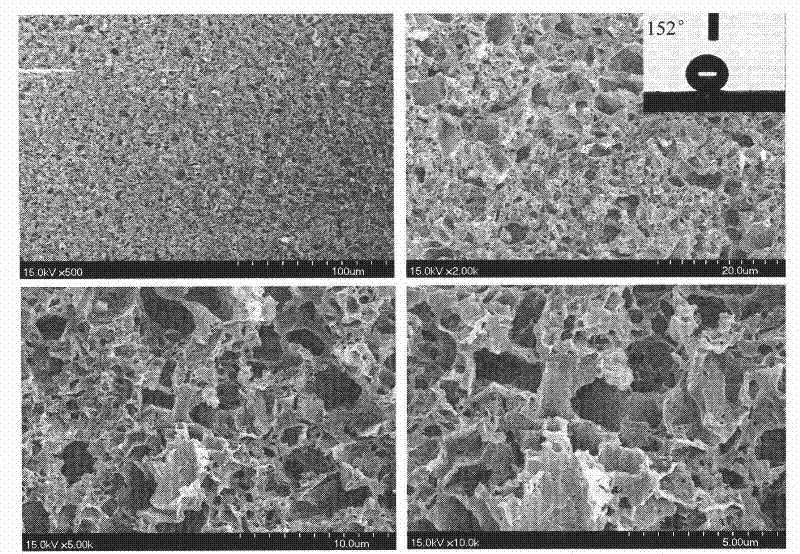

[0036] CaCO 3 - Acid etching of LDPE: Lifting of CaCO on cooled glass substrate 3 - LDPE film, put it in 30% hydrochloric acid solution, let it stand for 30 minutes, dry it with nitrogen gas after washing to get super-hydrophobic film, see surface microstructure and static water contact angle Figure 4 .

Embodiment 3

[0038] CaCO on glass surface 3 Thin layer preparation is as in Example 1.

[0039]Hot pressing of HDPE on the glass substrate: pile up a layer of HDPE particles (high-density polyethylene, Shanghai Secco Petrochemical Co., Ltd.) with a thickness of about 5mm on the prepared glass substrate, and put it together with another clean glass plate Heat it in an oven at 200°C for 10 minutes, then cover the clean glass plate on the HDPE, clamp it with two clips, keep it in the oven for another 5 minutes, take it out, and cool it to shape.

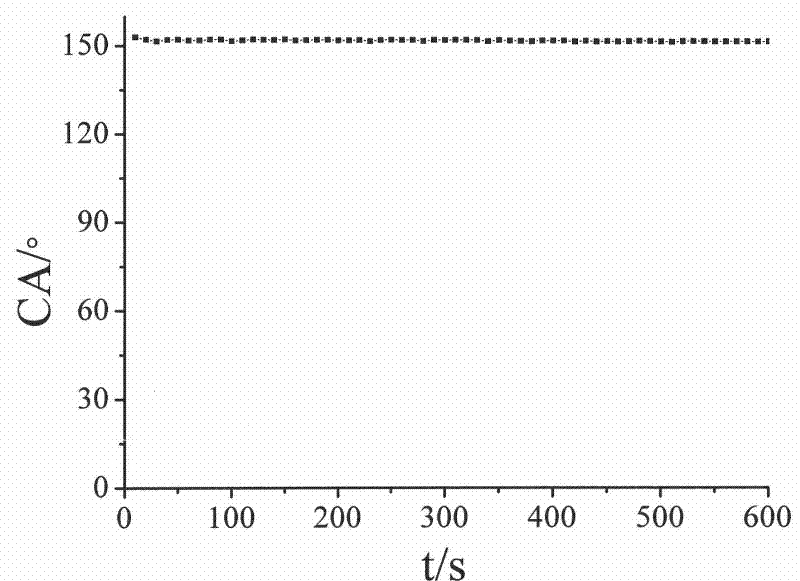

[0040] CaCO 3 - Acid etching of HDPE: Lifting of CaCO on cooled glass substrate 3 -HDPE film, put it into 30% hydrochloric acid solution, let it stand for 30 minutes, dry it with nitrogen after washing to get super-hydrophobic film, surface microstructure and static water contact angle see Figure 5 , the rolling photos of water droplets on the surface are shown in Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com