Structure of lever-type paper-bearing dish

A paper tray and lever-type technology, which is applied in the field of lever-type paper tray structure, can solve problems such as the inability to guarantee the self-rebound of the paper tray, unfavorable operating efficiency, and reduced operating force, so as to achieve enhanced convenience, labor-saving operation, and The effect of enhancing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

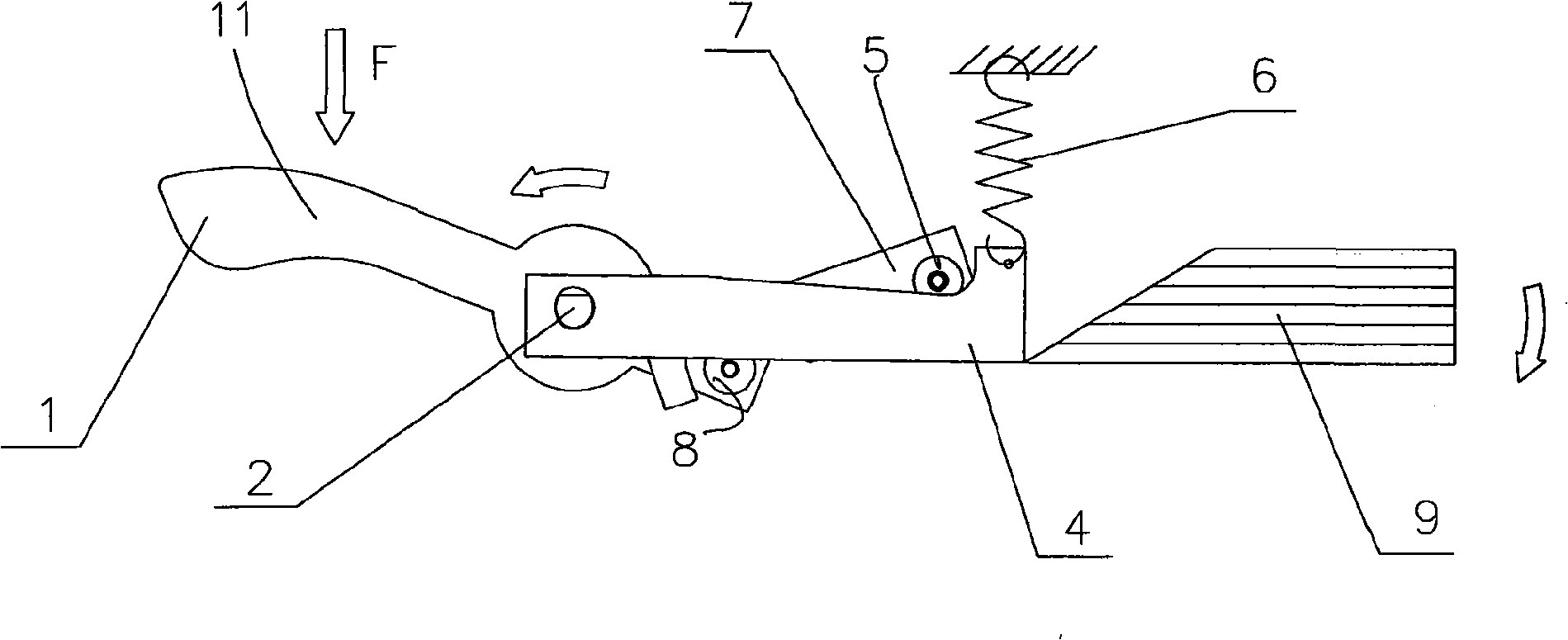

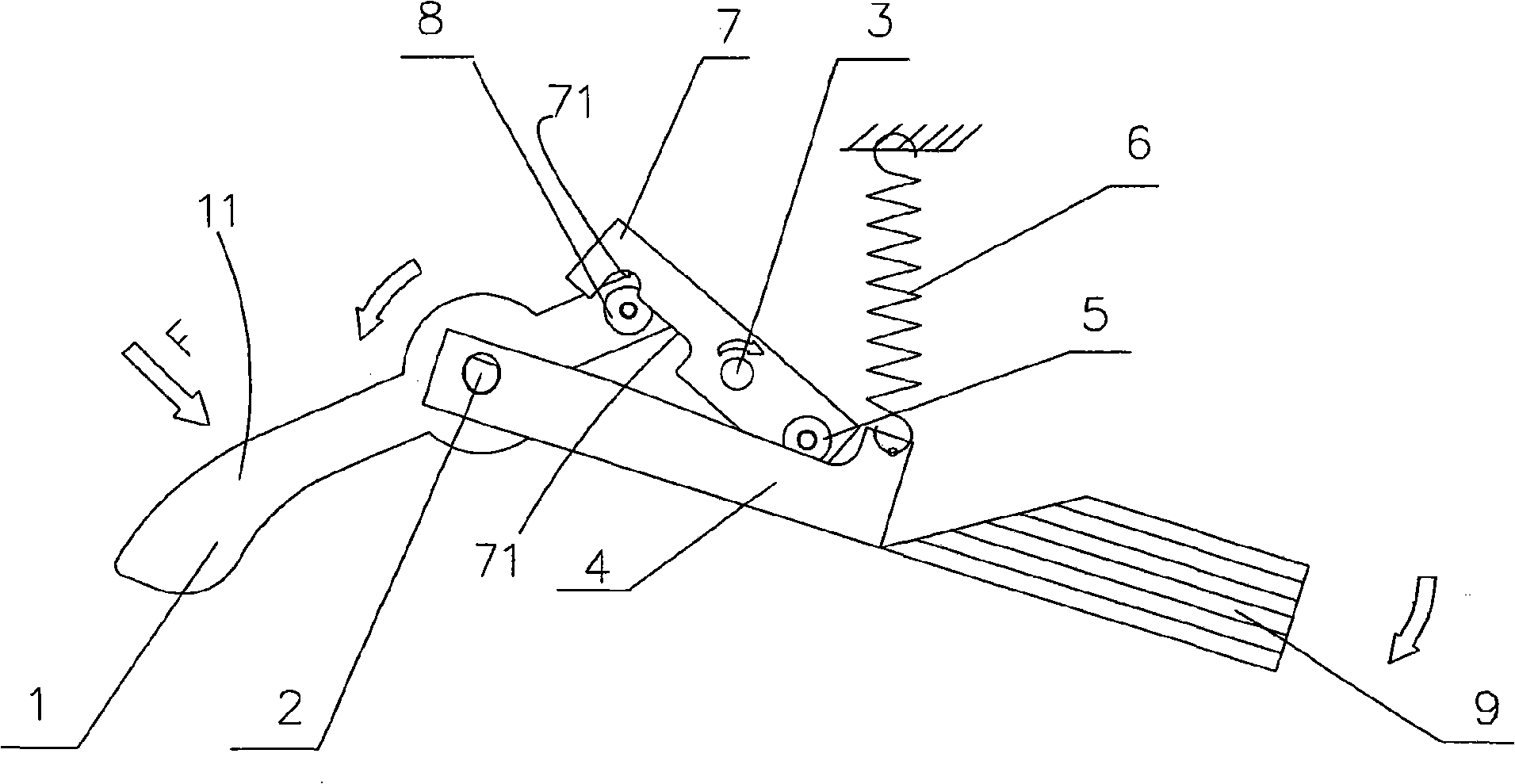

[0012] Such as Figure 1 to Figure 2 As shown, the icon numbers are as follows: handle 1, handle body 11, first rotating shaft 2, second rotating shaft 3, fixed block 4, buckle pulley 5, return spring 6, limit self-locking block 7, inner groove body 71, drive pulley 8, paper tray 9.

[0013] In the embodiment of the present invention, the lever type paper tray structure includes a fixed block 4 that can be fitted on one end of the paper tray 9, and the other end of the fixed block 4 is rotatably fitted with a fixedly installed first rotating shaft 2, the first rotating shaft 2. A handle 1 for cooperating rotation is set on the upper sleeve, and the tail end of the handle 1 is rotated and connected with a limited self-locking block 7, and the middle position of the limited self-locking block 7 is equipped with a second rotating shaft 3 that ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com