Heavy truck lifting machine moving method and special mechanical moving device thereof

A mobile device and lift technology, which is applied in the direction of lifting devices, motor vehicles, transportation and packaging, etc., can solve the problems of high cost, troublesome processing and use of hydraulic headstock, and achieve cost reduction, simple and convenient manufacturing and processing The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

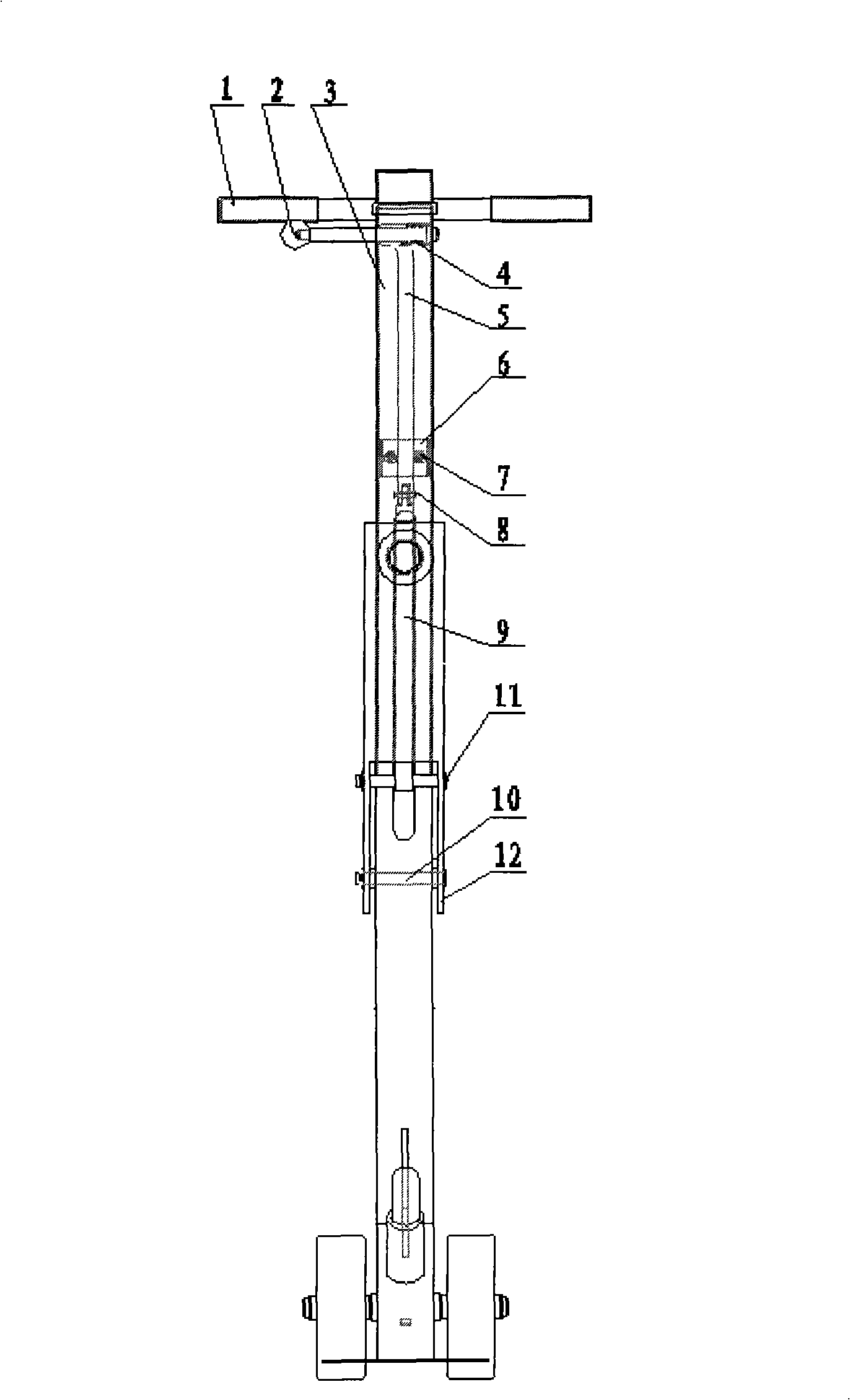

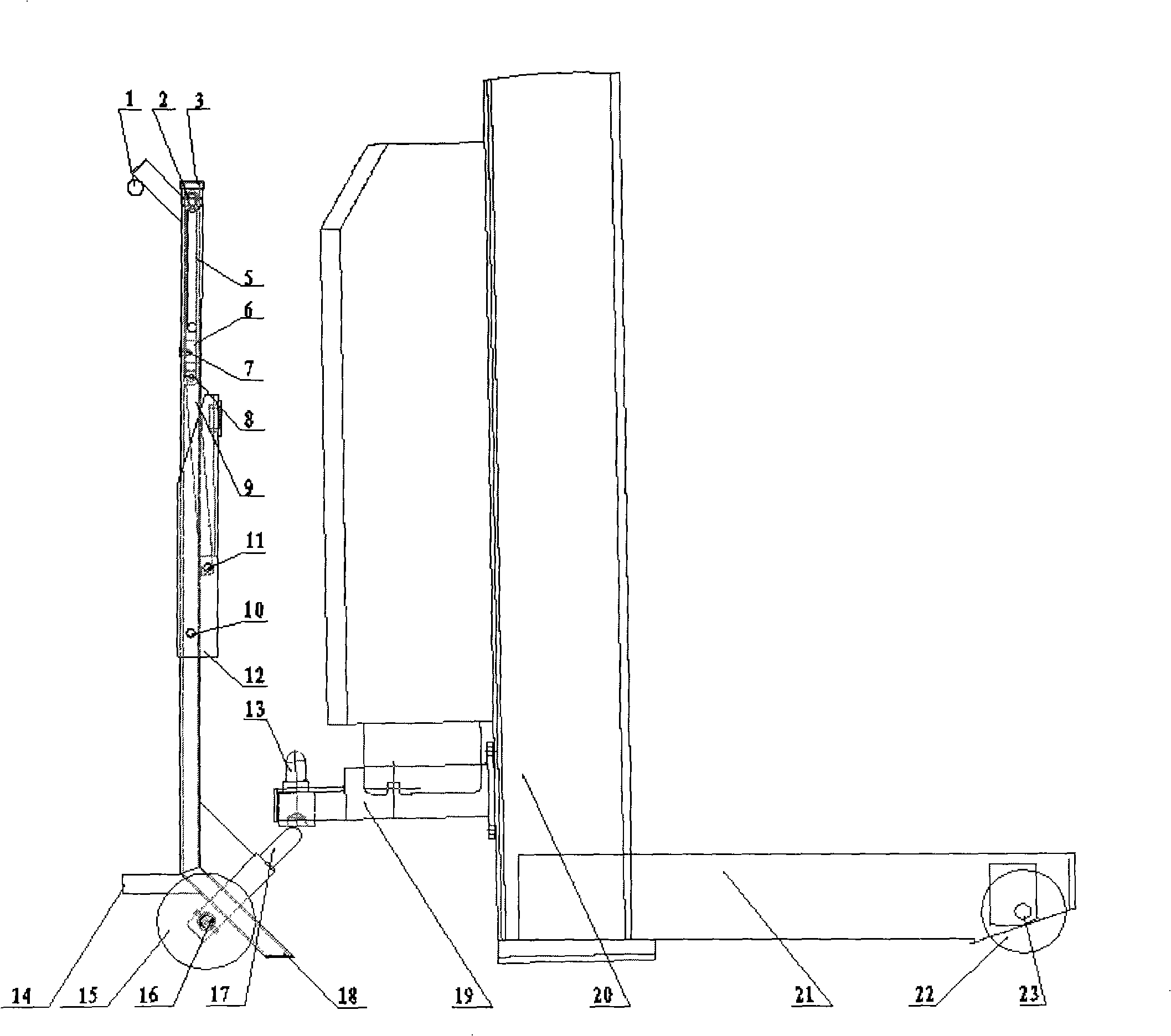

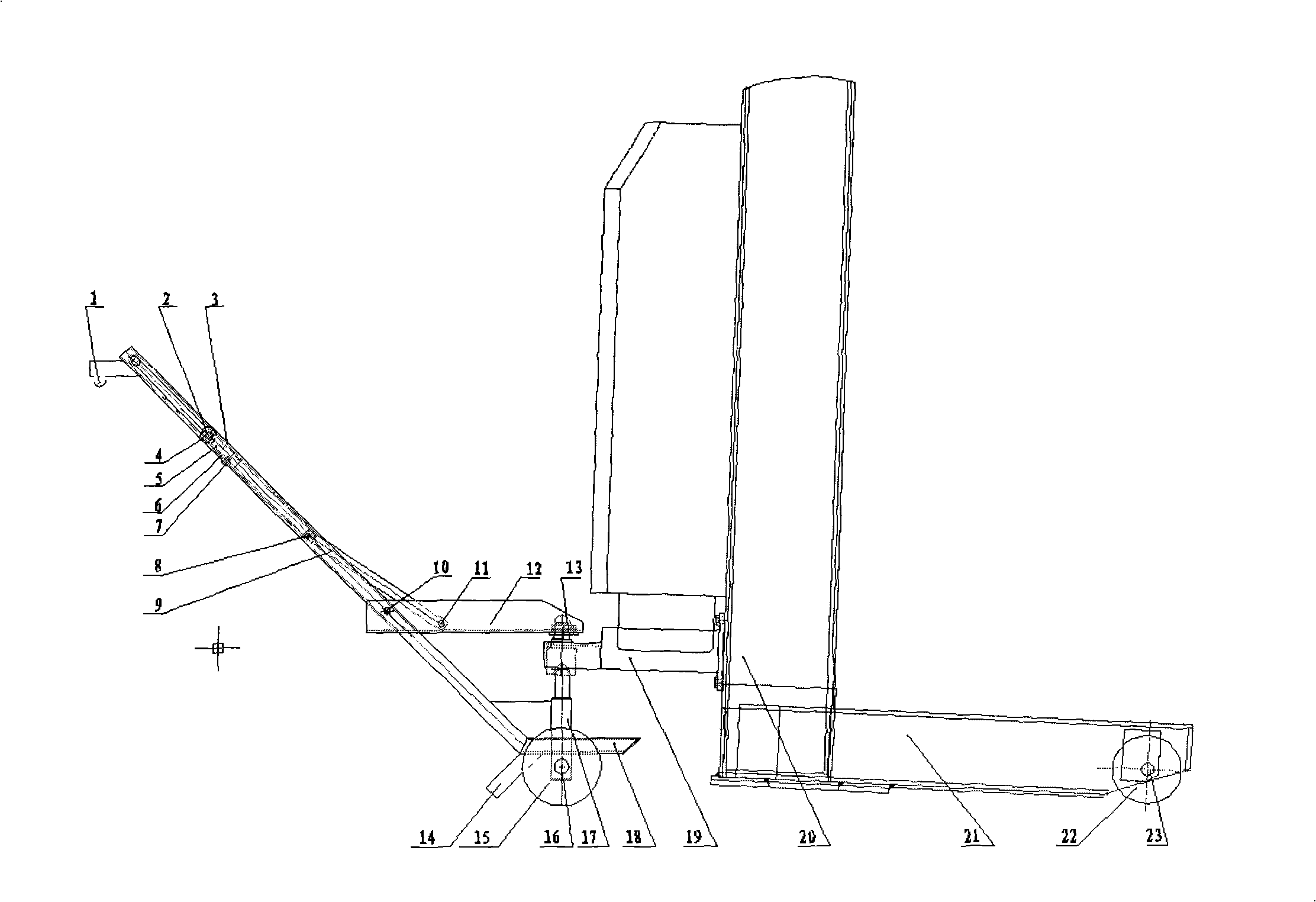

[0020] Such as figure 1 , 2 As shown, the special mechanical mobile device of the present invention comprises a car body 3, a pair of rear wheels 15 are installed at the bottom of the car body 3, specifically, the rear wheels 15 are movably connected with the first wheel shaft 16, and the first wheel shaft 16 is connected with the bottom of the car body 3. Fixed connection. The main handle 1 is also fixedly installed on the upper end of the vehicle body 3 .

[0021] The rear side of the bottom of the vehicle body 3 is fixed with a tailgate pipe 14 . A top pillar 17 and a front strut 18 are fixed on the front side of the bottom of the vehicle body 3 .

[0022] A guide block 6 with a longitudinal through hole is fixedly installed in the car body 3 by screws 7 . The upper end of the guide rod 5 slidably installed in the longitudinal through hole is fixedly connected with the inner end of the handle seat 4 covered with the auxiliary handle 2, and the lower end of the guide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com