Upper-lower-cover split-type bottle cap tightening machine

A technology of screwing machine and bottle cap, which can be used in the direction of tightening the container with the cap, filling the bottle, liquid processing, etc., which can solve the problem of large labor and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

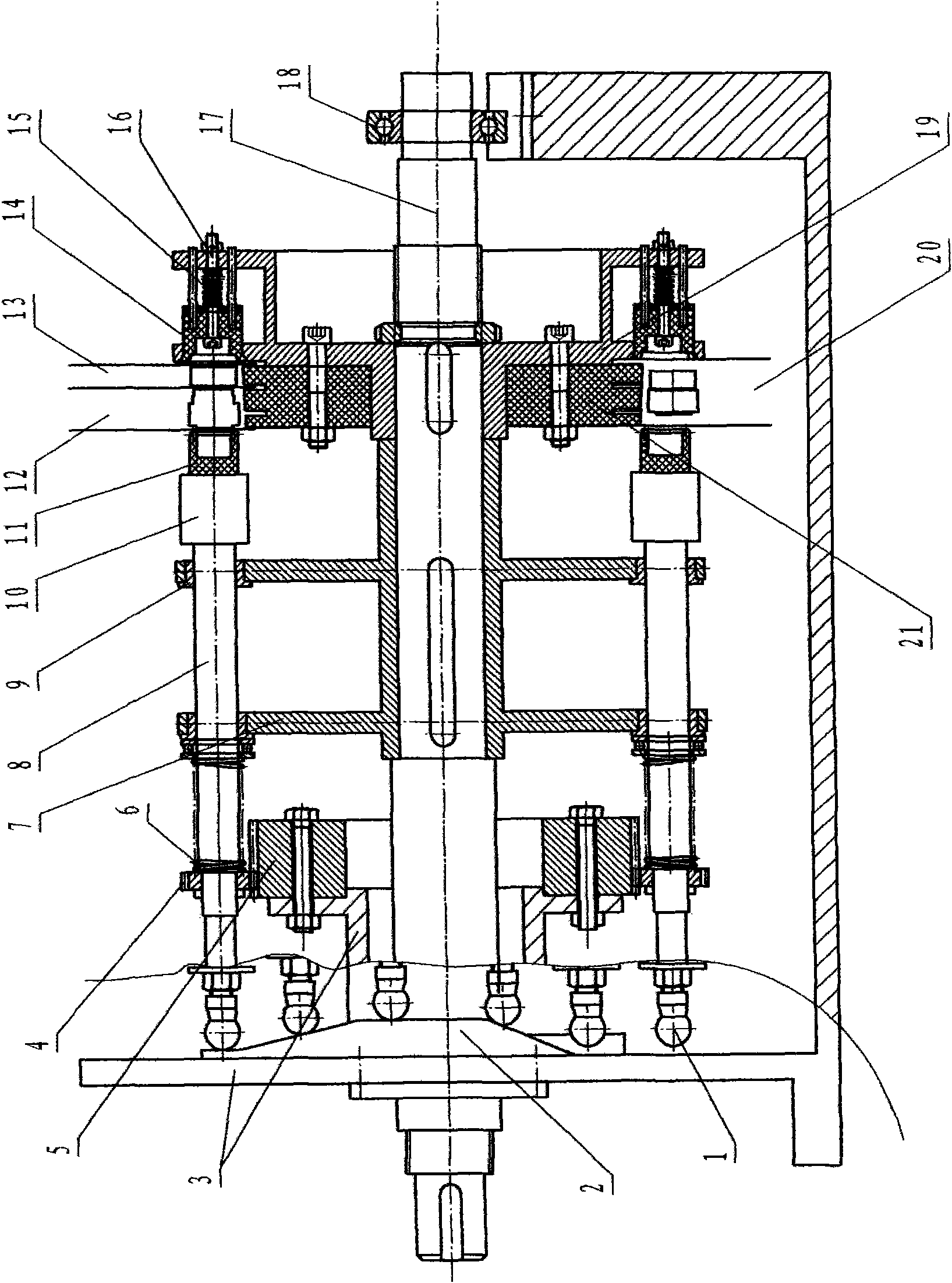

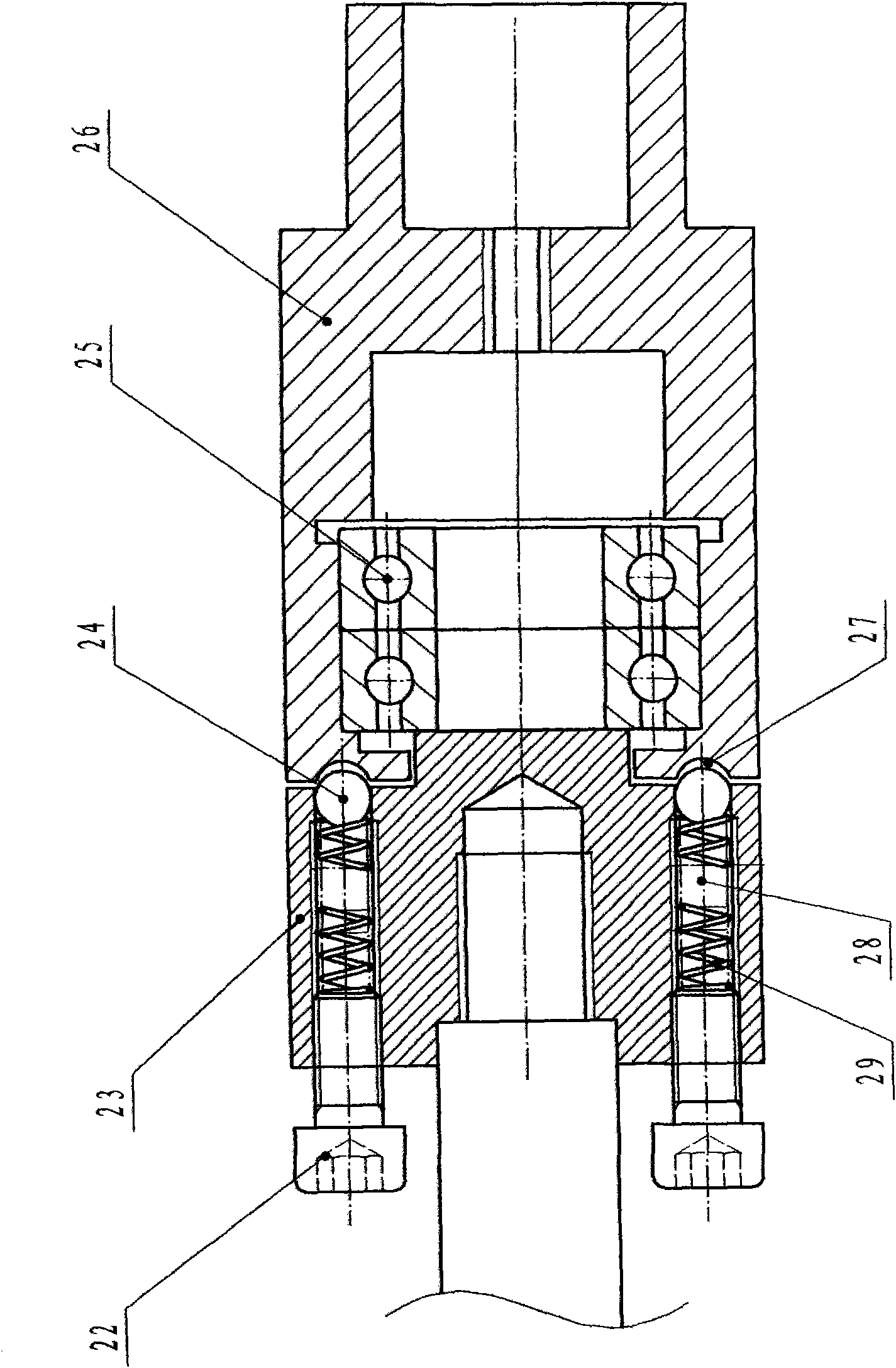

[0012] refer to figure 1 , the bottle cap screwing machine with upper and lower caps separated, including a base 3, a main shaft 17, an upper cap gripper 14, a gripper rod 16, a lower cap die 11, a gripper turntable 19, and a bottle cap turntable 21 , ejector rod 8, ejector rod turntable 7, fixed gear 5, rotating gear 4, force limiting device 10, pulley 1 and convex rail 2, upper cover conveying path 13, lower cap conveying path 12, bottle cap output path 20; main shaft 17 Fixed on the base 3 through the bearing 18; the fixed gear 5 is fixedly connected to one side of the base 3; Sliding bearing 9 is movably and fixedly connected on the mandrel turntable 7; grip bar 16 is fixedly connected on the grip turntable 19, and loam cake gripper 14 is movably connected on the grip bar 16 and is movably arranged on the grip turntable 19; The force device 10 is arranged between the ejector rod 8 and the top mold 11 of the lower cover, and the top mold 11 of the lower cover is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com