Measurement circuit and measurement method for rotation speed of CW type electric eddy current dynamometer

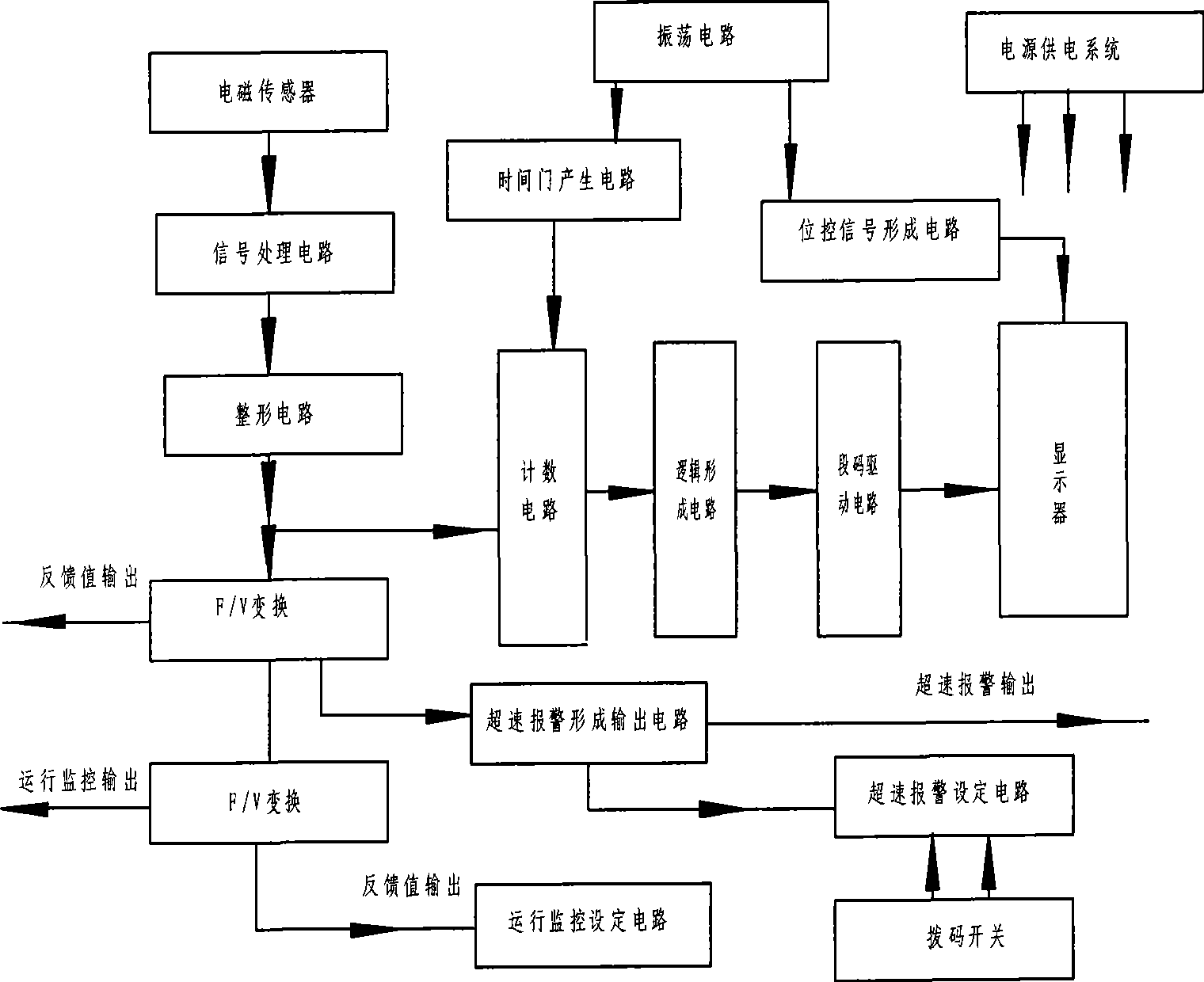

An eddy current dynamometer and rotational speed measurement technology, which is applied in the direction of linear/angular velocity measurement, velocity/acceleration/shock measurement, measuring device, etc., can solve the problems of component production, low supporting efficiency, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

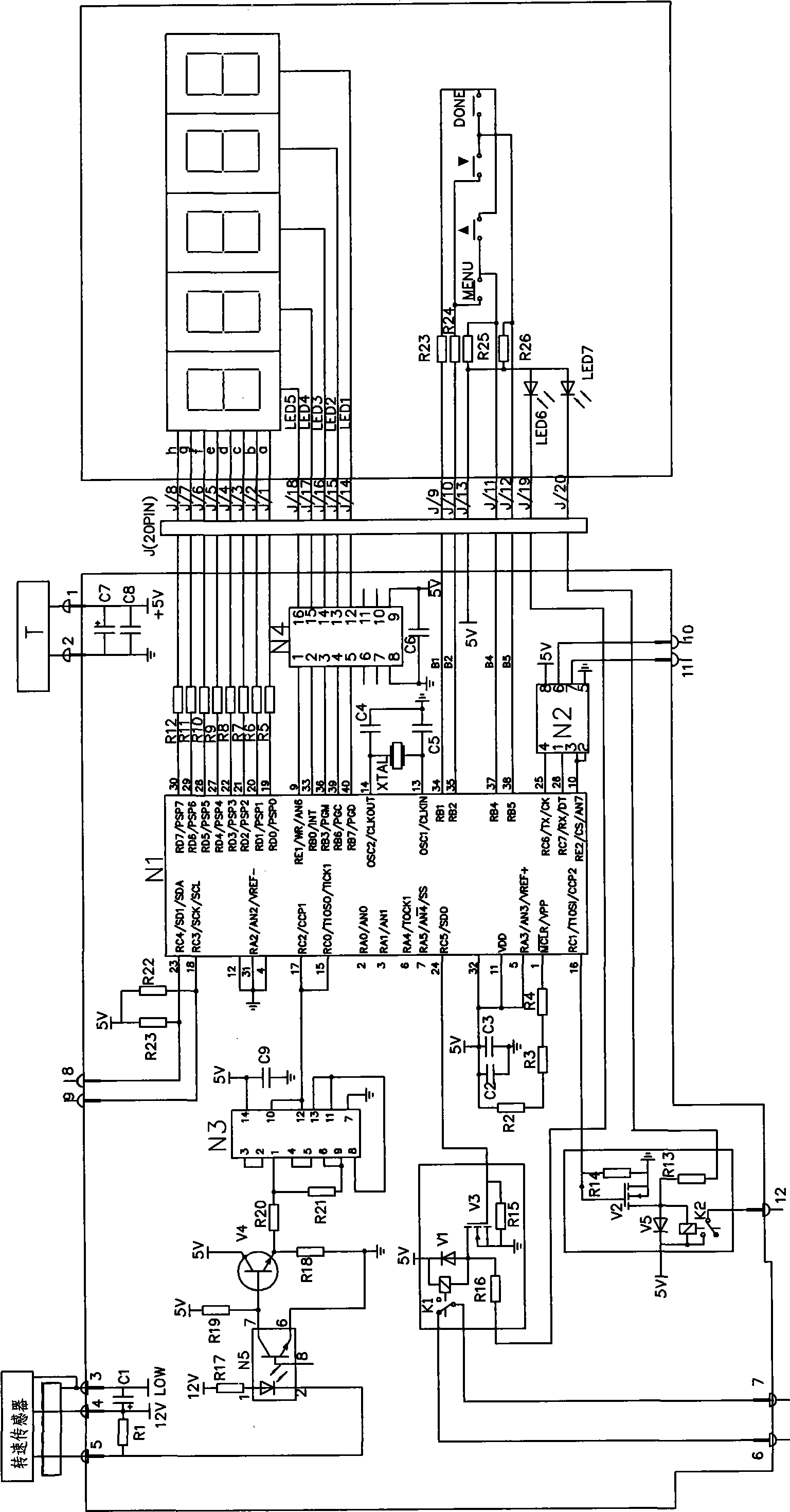

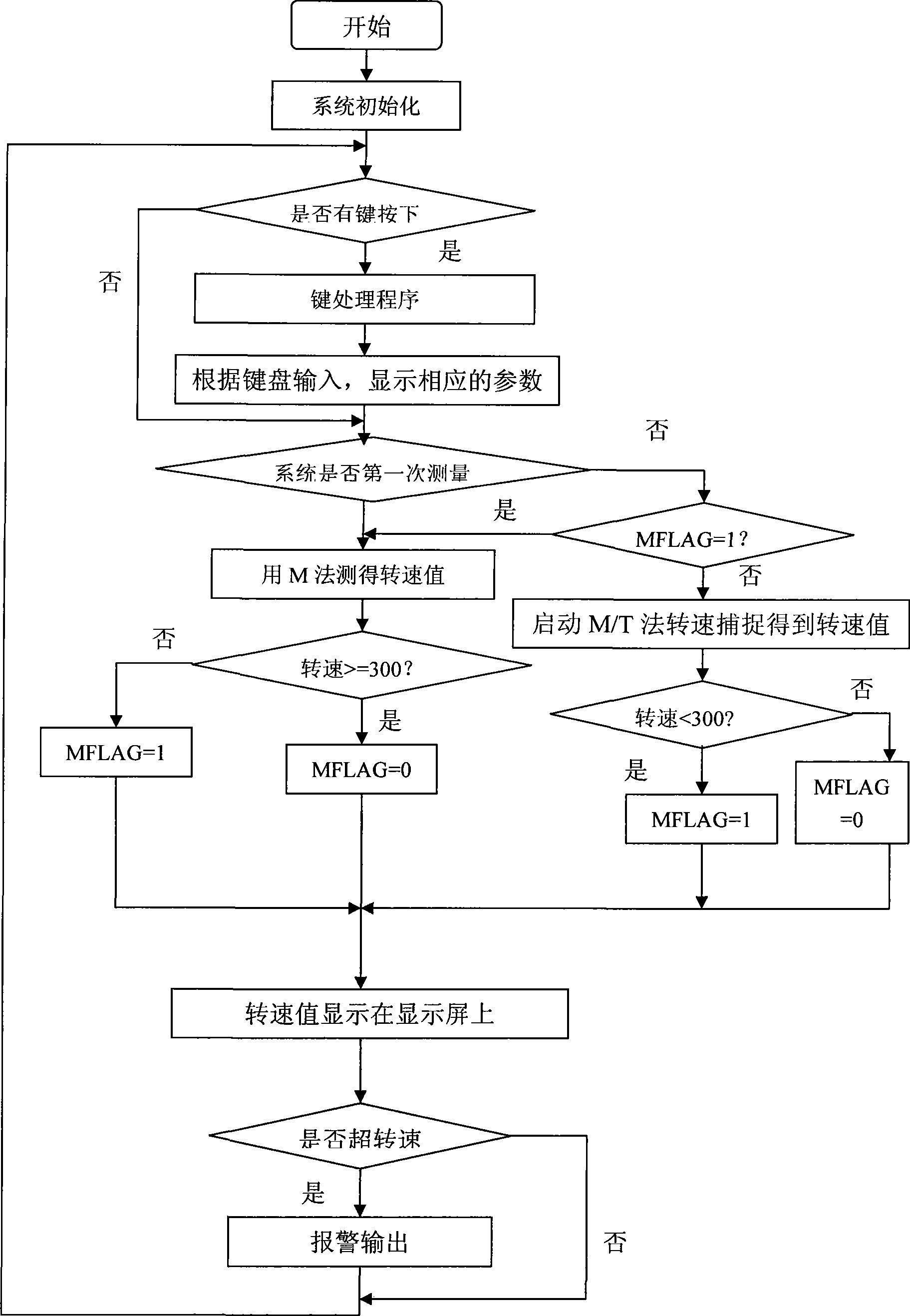

[0055] A speed measurement circuit for a CW type eddy current dynamometer, including a speed sensor, a speed signal processing module, a control module, and a display module, wherein: the speed signal processing module includes a signal processor N1, a speed signal sorting circuit, and a speed sensor The signal output terminal is connected to the rotational speed signal input terminal of the signal processor N1 through the rotational speed signal finishing circuit, the display signal output terminal of the signal processor N1 is connected to the display signal input terminal of the display module, and the control signal input terminal of the signal processor N1 is connected to the control The control signal output terminal of the module.

[0056] The schematic diagram of the speed measurement circuit is as follows: figure 2 As shown, the signal processor N1 adopts a single-chip microcomputer model of PIC16F877; the speed signal finishing circuit includes a photocoupler N5 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com