Liquid crystal display device

A liquid crystal display and device technology, applied in the field of liquid crystal display devices, can solve problems such as uneven display and failure to return to the orientation state, and achieve the effect of suppressing uneven display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

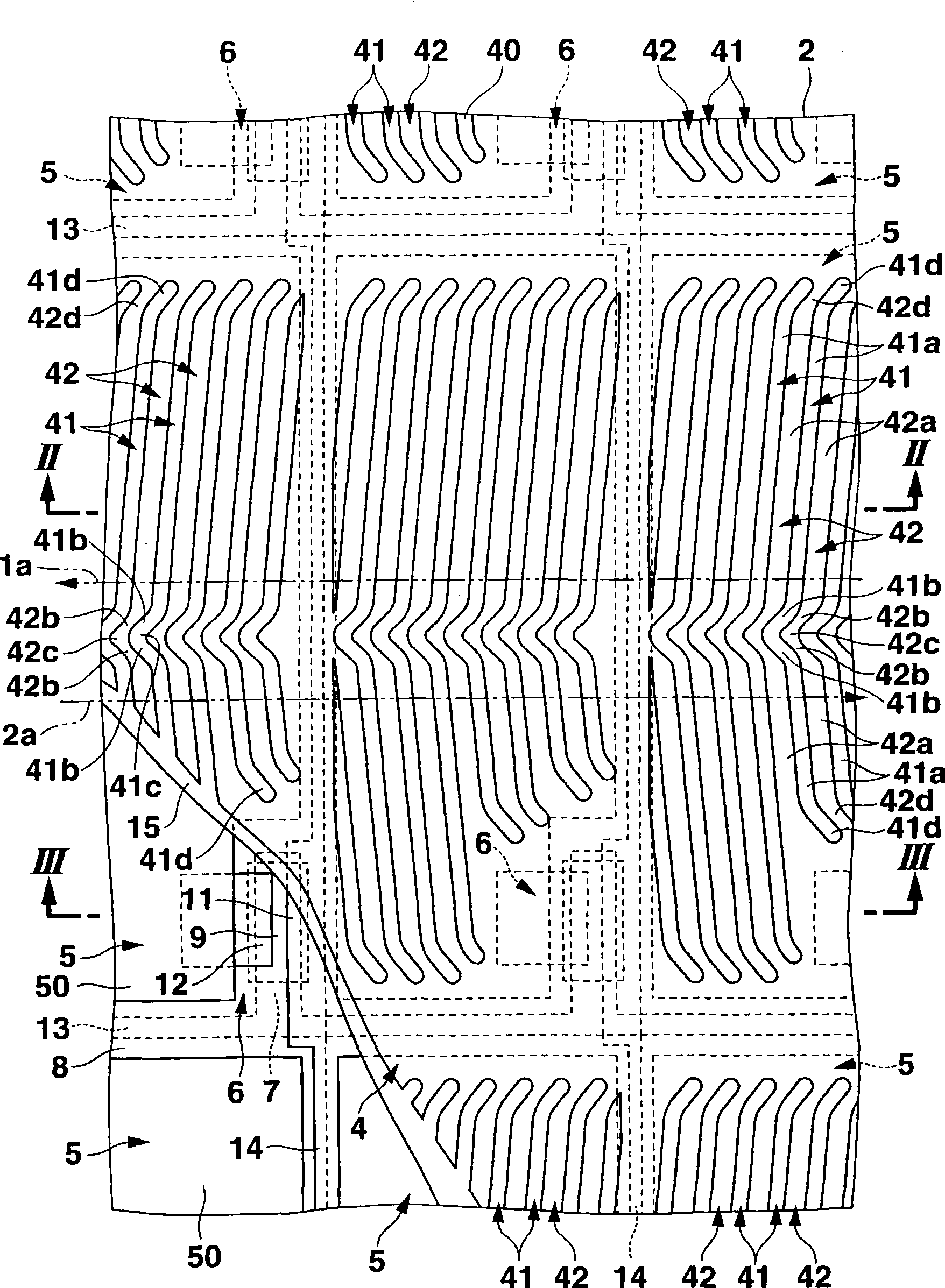

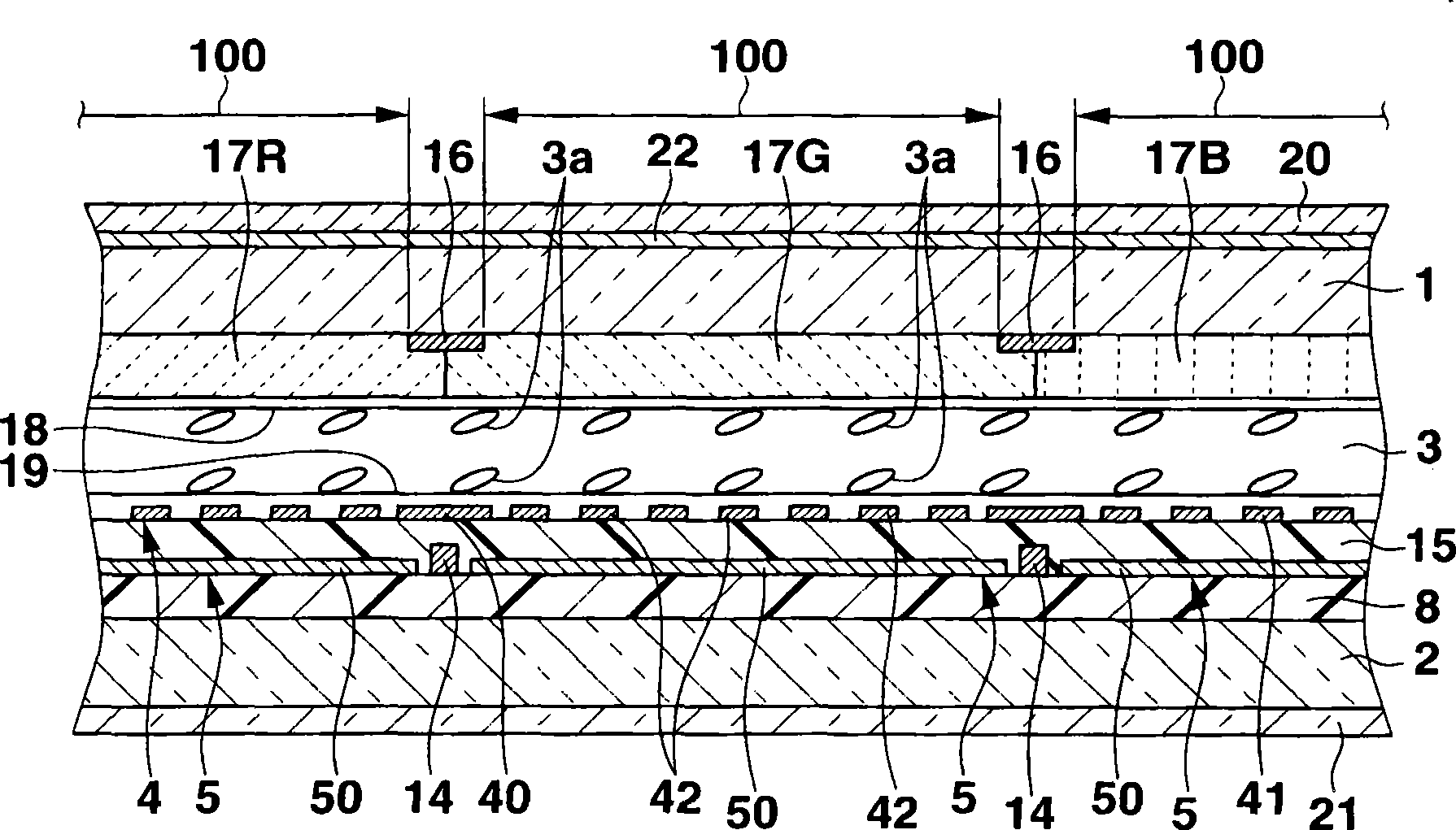

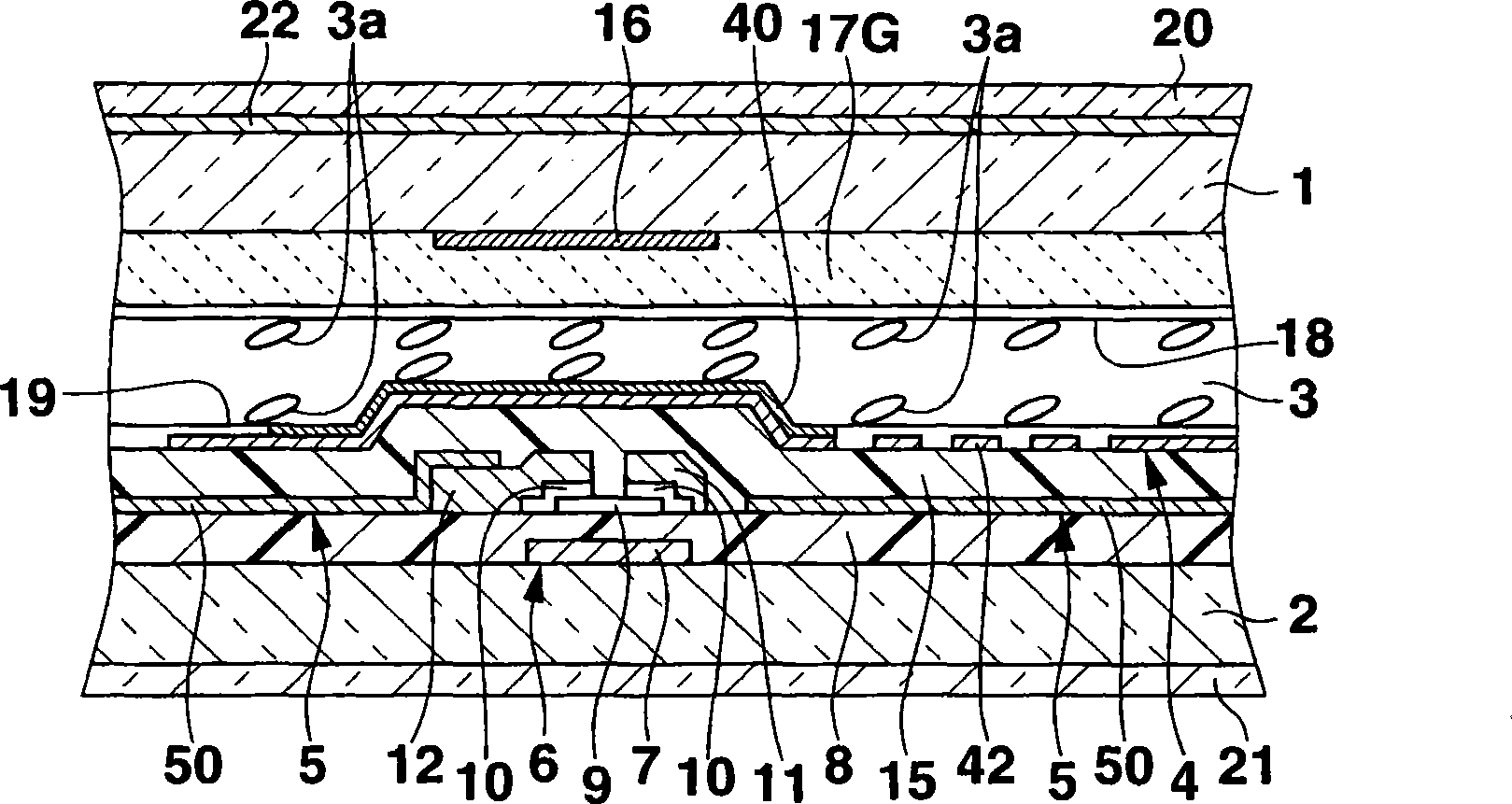

[0024] Figure 1 ~ Figure 7 Showing the first embodiment of the present invention, figure 1 It is a top view of a part of a substrate of a liquid crystal display device. figure 2 Is along with the above liquid crystal display device figure 1 Sectional view taken on line II-II. image 3 Is along with the above liquid crystal display device figure 1 Sectional view taken on line III-III.

[0025] Such as Figure 1 ~ Figure 3 As shown, the liquid crystal display device has: an observation side ( figure 2 with image 3 The upper side) and a pair of transparent substrates 1 and 2 on the opposite side thereof. The pair of transparent substrates 1, 2 are arranged facing each other with a predetermined gap, and the alignment films 18, 19 are respectively provided on the inner surfaces facing each other and implemented The orientation process of the directions 1a, 2a that are parallel to each other and opposite to each other; the liquid crystal layer 3 is sealed in the gap between the ...

no. 2 Embodiment approach

[0118] Figure 8 with Picture 9 Showing the second embodiment of the present invention, Figure 8 It is a plan view of a part of a substrate of a liquid crystal display device, Picture 9 It is an enlarged cross-sectional view of a part of one pixel of the above-mentioned liquid crystal display device. In addition, in this embodiment, the parts corresponding to the above-mentioned first embodiment are denoted by the same reference numerals in the figure, and the description thereof is omitted.

[0119] In the liquid crystal display device of this embodiment, a plurality of pixel electrodes 5 are formed by a transparent conductive film (for example, an ITO film) 50a, and the transparent conductive film 50a corresponds to a predetermined area for forming one pixel, and is located in the transparent conductive film 50a. The transparent conductive film 50a is provided with a plurality of electrode portions 51 in common connection with each other, and the plurality of electrode porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com