Semiconductor device manufacturing method

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、半导体/固态器件零部件等方向,能够解决焊剂成分、柱电极高度偏差、柱电极的下部与电极不能接合等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

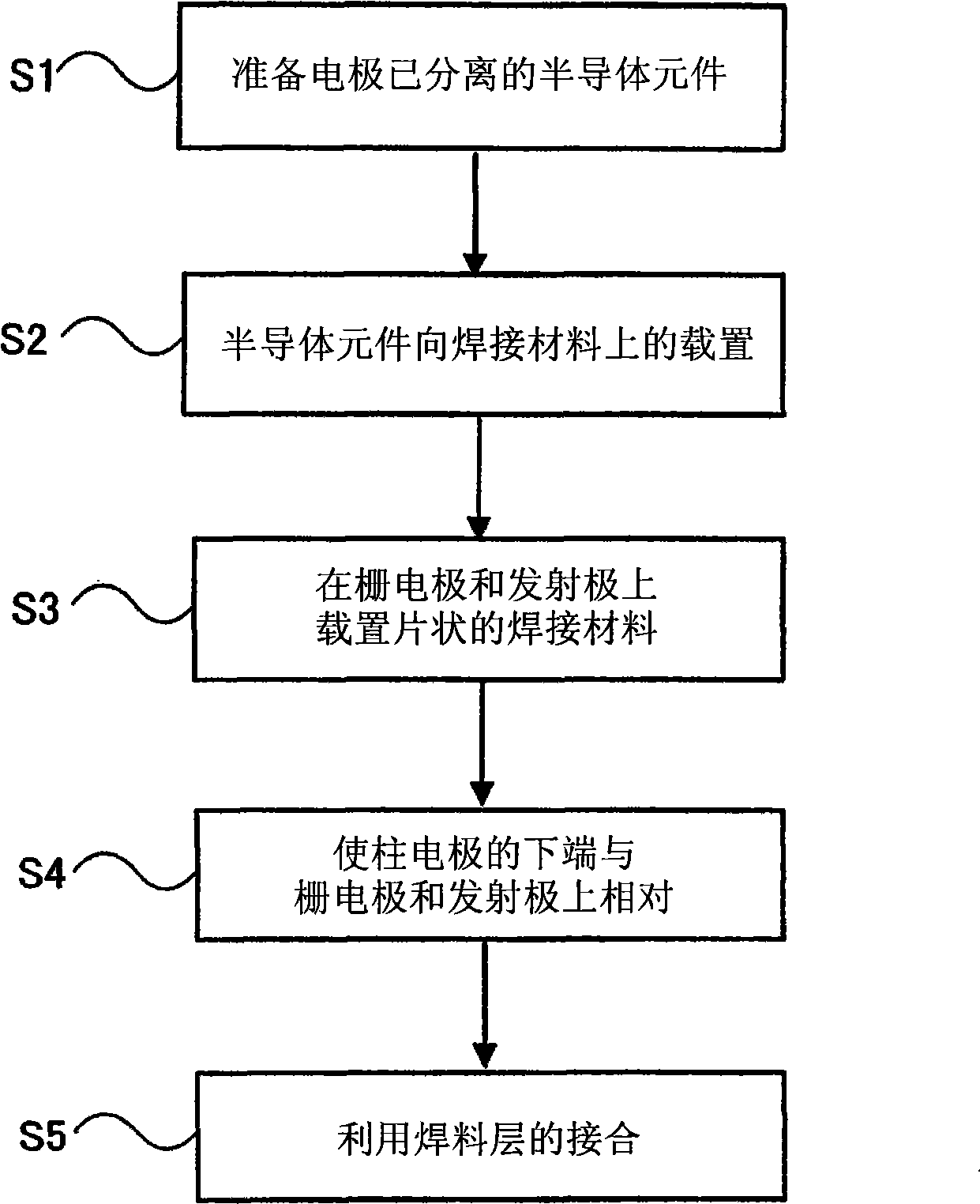

[0059] Hereinafter, the method of manufacturing the semiconductor device according to the first embodiment will be described in detail with reference to the drawings.

[0060] figure 1 It is a flowchart for explaining the manufacturing method of the semiconductor device of 1st Embodiment. In the manufacturing method of the semiconductor device according to the first embodiment, for example, a case where a vertical IGBT (Insulated Gate Bipolar Transistor: Insulated Gate Bipolar Transistor) element is used as a semiconductor element is exemplified. The semiconductor element used in the manufacturing method is not limited to the IGBT element.

[0061] First, prepare a semiconductor element (step S1), the semiconductor element is respectively provided with at least one gate electrode (first electrode) as a control electrode and an emitter electrode (second electrode) as a main electrode, and has a gate electrode (second electrode) configured to be connected to the gate electrode...

no. 2 approach

[0202] Next, use Figure 14 ~ Figure 19 A specific manufacturing method of the semiconductor device manufacturing method of the second embodiment will be described. In addition, in all the drawings shown below, the above-mentioned Figure 2 to Figure 13 The same symbols are assigned to the same components, and detailed description thereof will be omitted.

[0203] Figure 14 ~ Figure 19 It is a figure for demonstrating the manufacturing method of the semiconductor device of 2nd Embodiment.

[0204] First, if Figure 14 As shown, semiconductor elements 10, 15 are prepared. These semiconductor elements 10 and 15 are fixed and supported by carbon fixing jigs (not shown).

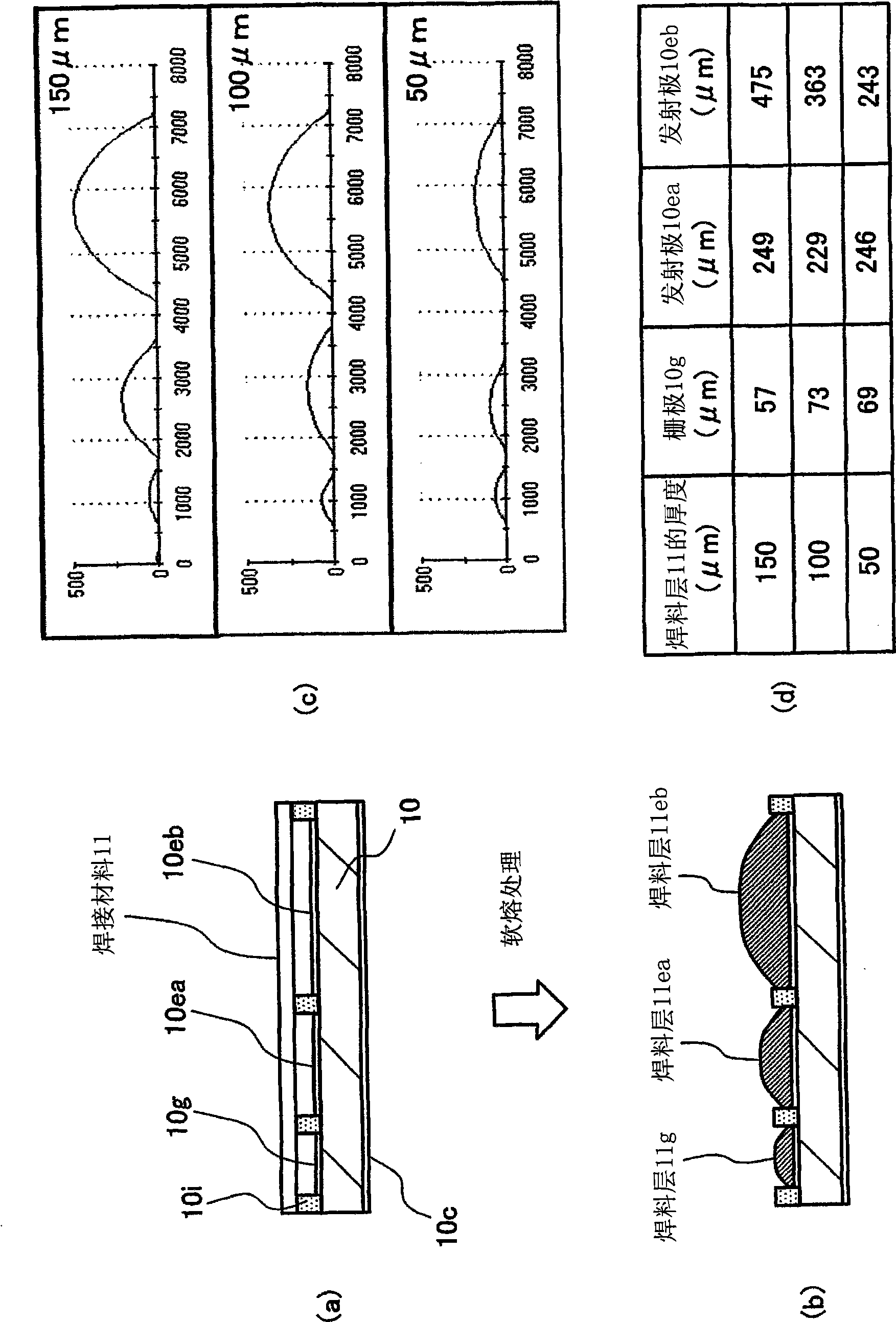

[0205]Next, the sheet-shaped solder material (first conductive bonding material) 11 is supported by the insulating layer 10i disposed on the upper surface side of the semiconductor element 10, so that the main surface of the solder material 11 faces the gate electrode 10g and the emitter electrodes 10ea, 1...

no. 3 approach

[0264] Next, use Figure 20 A specific manufacturing method of the semiconductor device manufacturing method of the third embodiment will be described. In addition, in all the drawings shown below, the above-mentioned Figure 2 to Figure 19 The same symbols are assigned to the same components, and detailed description thereof will be omitted.

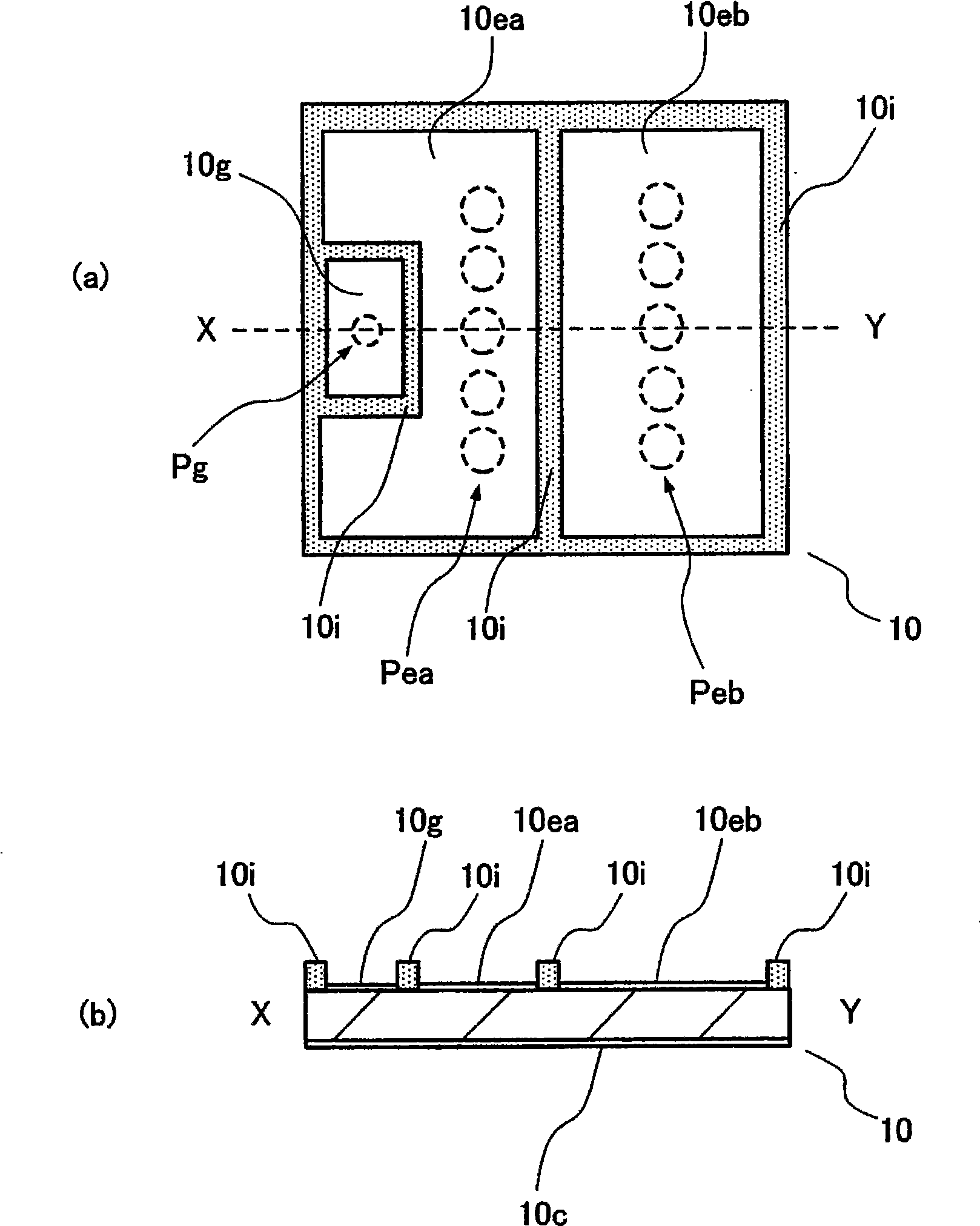

[0265] Figure 20 Modifications of the semiconductor element 10 used in the method of manufacturing the semiconductor device according to the third embodiment are exemplified in FIG. here, Figure 20 (a), Figure 20 (b), Figure 20 (c), means along the figure 2 A cross-sectional view of the semiconductor element 10 at the position of the dotted line X—Y.

[0266] For example, the insulating layer 10i that separates the gate electrode 10g and the emitter electrode 10ea of the semiconductor element 10, or the insulating layer 10i between the emitter electrodes 10ea and 10eb, such as Figure 20 As shown in (a), it may be tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com