Full-automatic double ultrasonic U-shaped upstops of nylon zip fastener

An ultrasonic and fully automatic technology, applied in applications, household appliances, fastener components, etc., can solve the problems of high manufacturing cost and large volume, and achieve the effects of stable product quality, high production efficiency and reliable performance

Active Publication Date: 2009-10-07

广州市振宇拉链机械有限公司

View PDF1 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the existing full-automatic nylon zipper ultrasonic U-type double top stop machine has large volume and high manufacturing cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

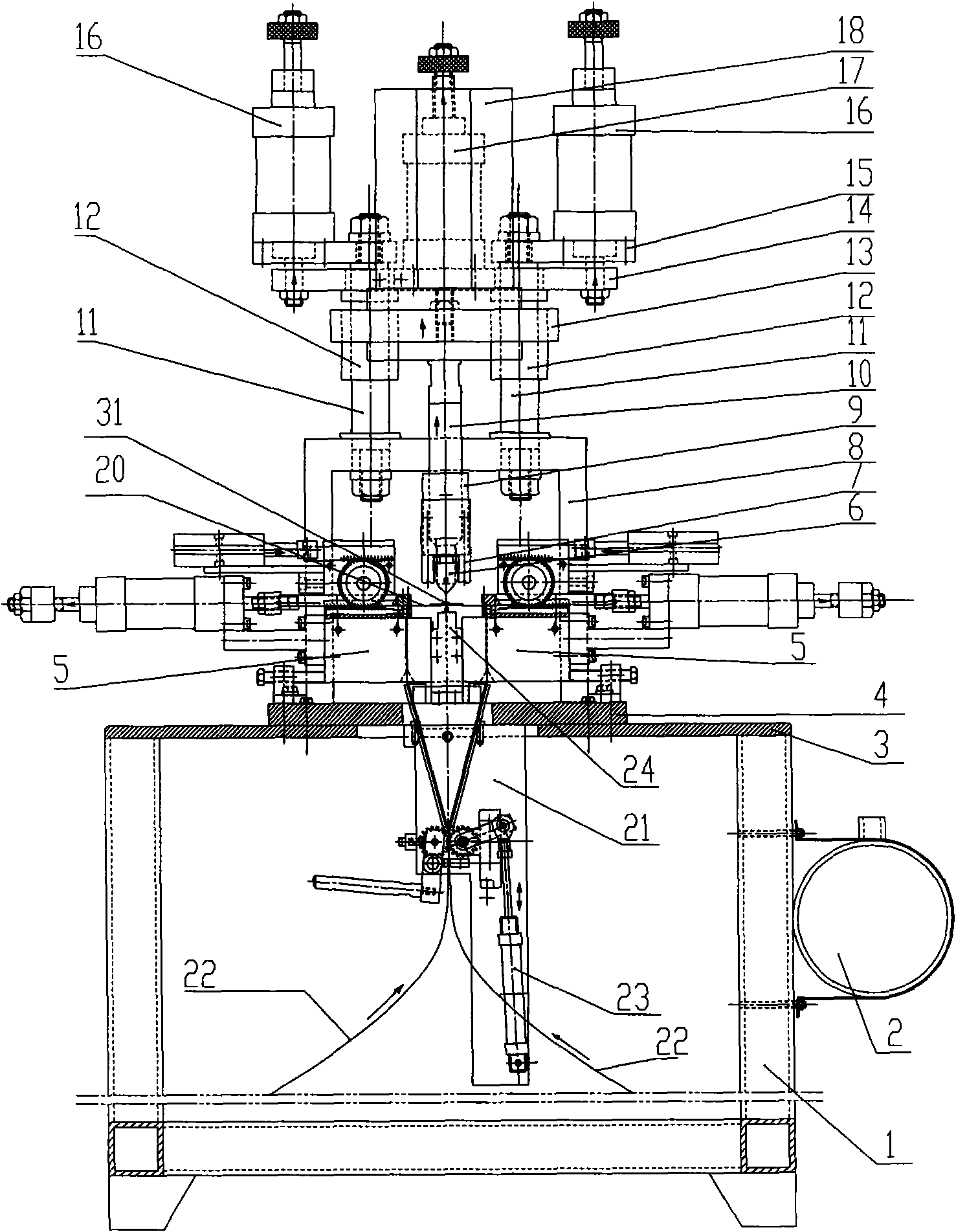

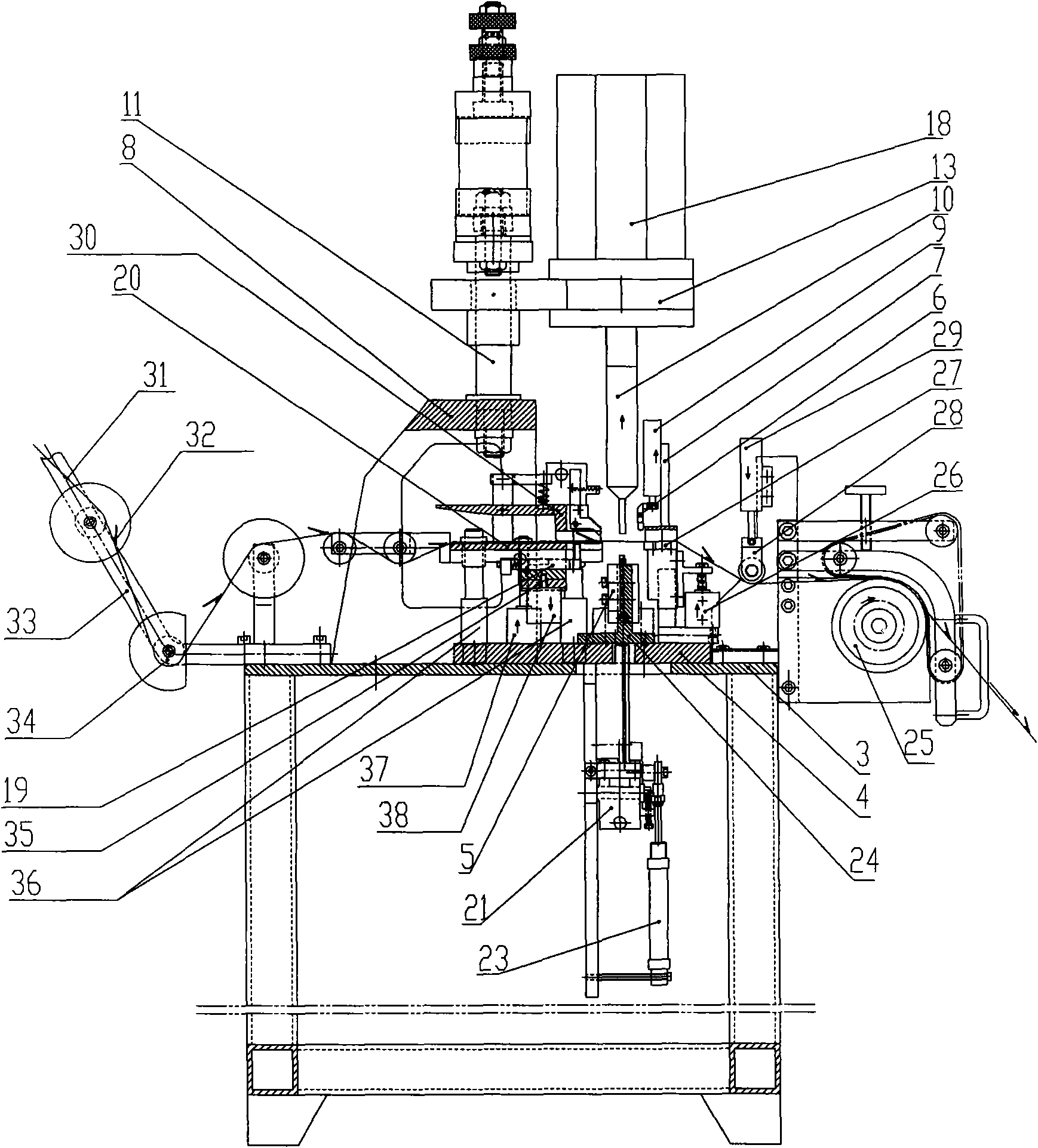

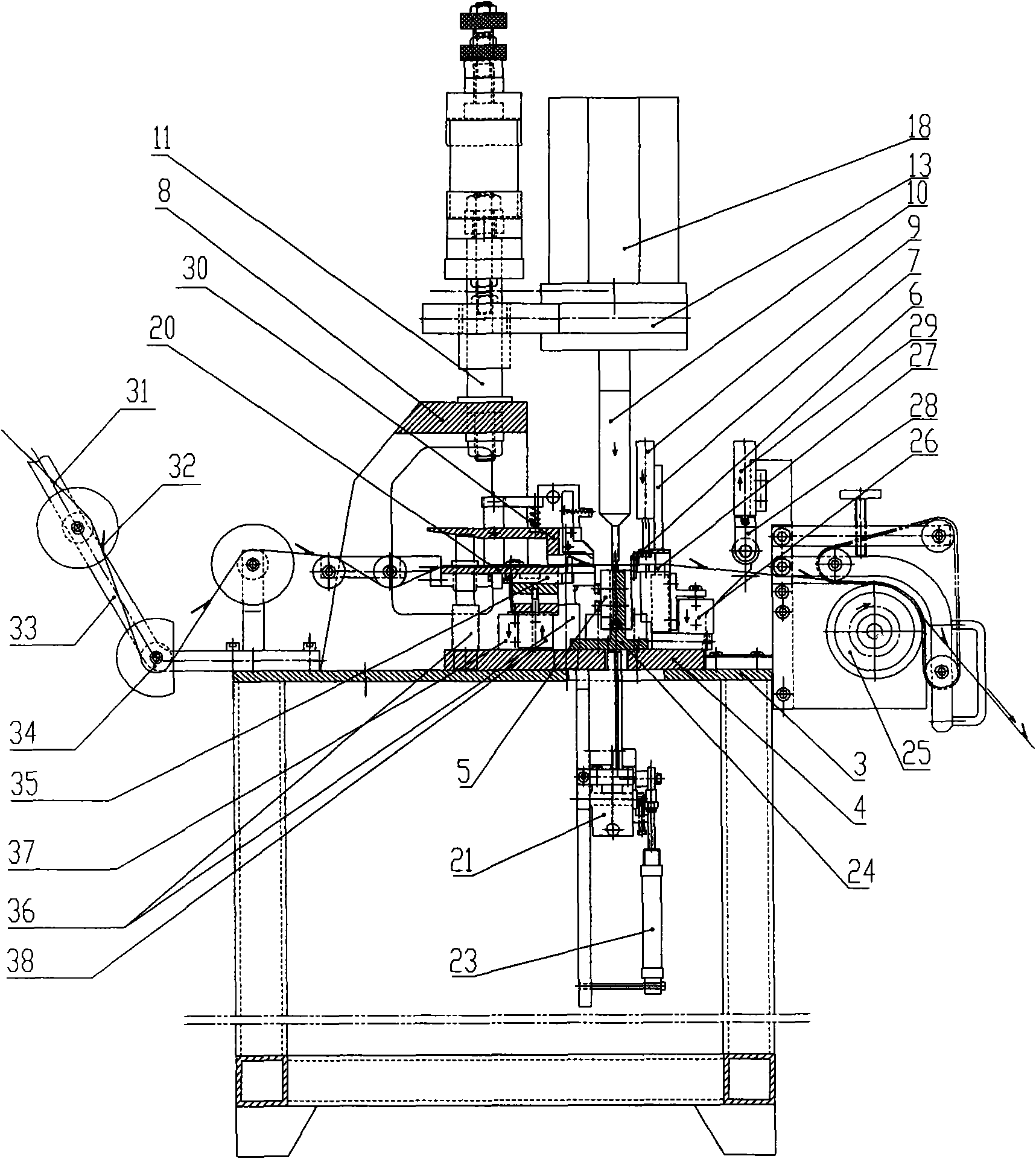

The invention discloses full-automatic double ultrasonic U-shaped upstops of a nylon zip fastener, comprising a stand, a plastic flat wire cutting and bending forming mechanism, a chaining-passing positioning mechanism, a pull head signal inducing mechanism, an elastic zip fastener mechanism, a chain-dividing mechanism and a welding and melding mechanism. The invention utilizes the ultrasonic melding technology, uses one welding head to simultaneously meld the U-shaped plastic flat wire upstops at the left and the right of the nylon zip fastener by a full-automatic production mode, and has the advantages of reasonable structure, reliable performance, high production efficiency, stable product quality, and the like.

Description

technical field [0001] The invention relates to a nylon zipper production equipment, specifically a full-automatic nylon zipper ultrasonic U-shaped double top stop machine. Background technique [0002] The existing fully automatic nylon zipper ultrasonic U-shaped double top stop machine uses two sets of vibrating electric boxes, vibrators, and welding heads to weld the U-shaped double top stop of the nylon zipper at the same time, and molds the plastic flat wire The way to reach the U-shaped upper stop is the same as that of the traditional bottom stop machine, which requires inner and outer cutters, telescopic dies, and punches. Therefore, the existing full-automatic nylon zipper ultrasonic U-shaped double top stop machine has large volume and high manufacturing cost. Contents of the invention [0003] Aiming at the deficiencies in the prior art, the present invention aims to provide a fully automatic nylon zipper ultrasonic U-shaped double top stop machine. [0004] T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C65/74B29C65/78B29C65/08B29K77/00B29L5/00

Inventor 顾振财

Owner 广州市振宇拉链机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com