Box-manufacturing device

A blank and paper feeding section technology, applied in the field of box-making devices, can solve problems such as difficult detection of red dirt, defects in blanks, and difficult inspection, and achieve the effects of saving installation space, reducing costs, and saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

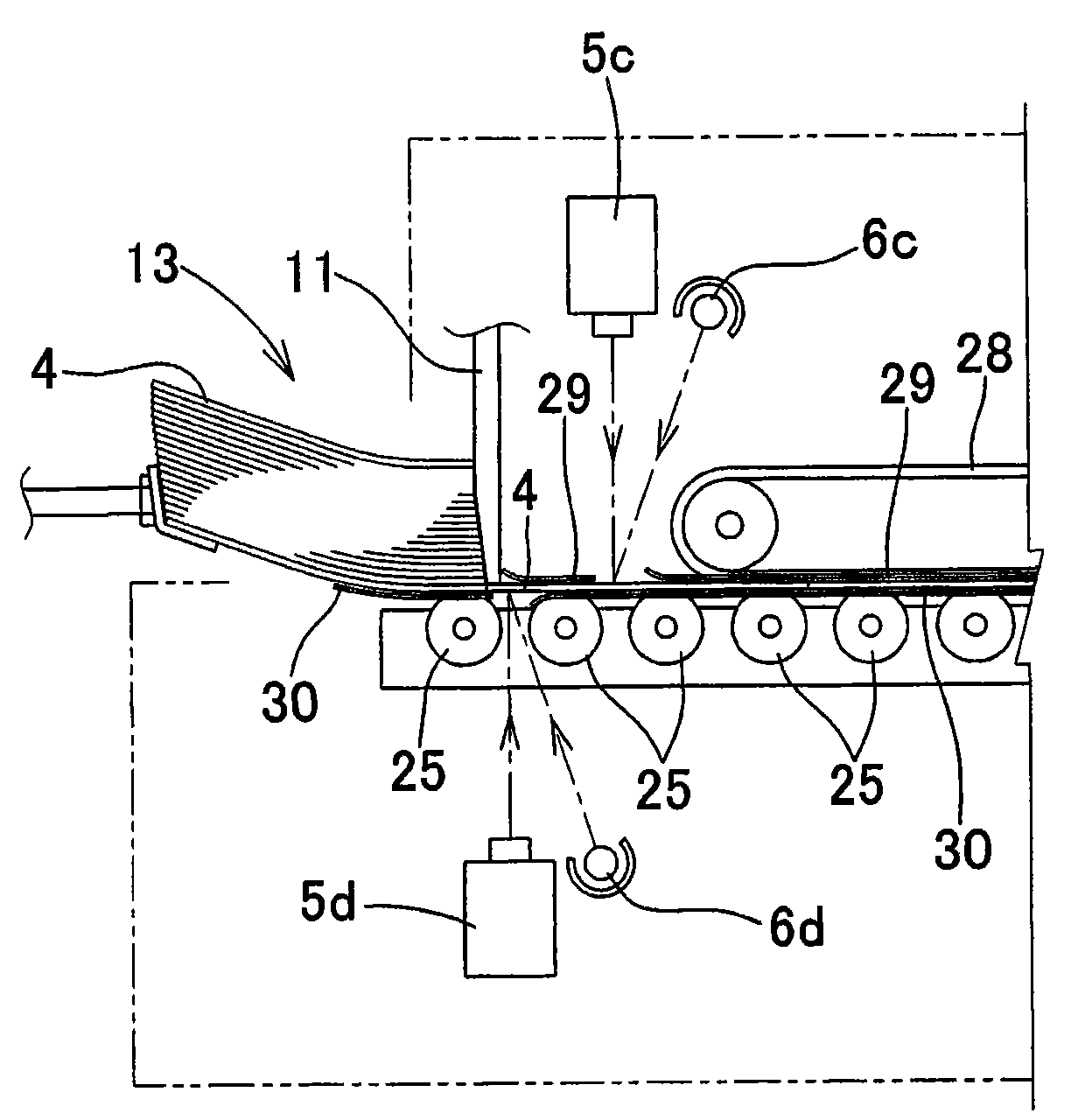

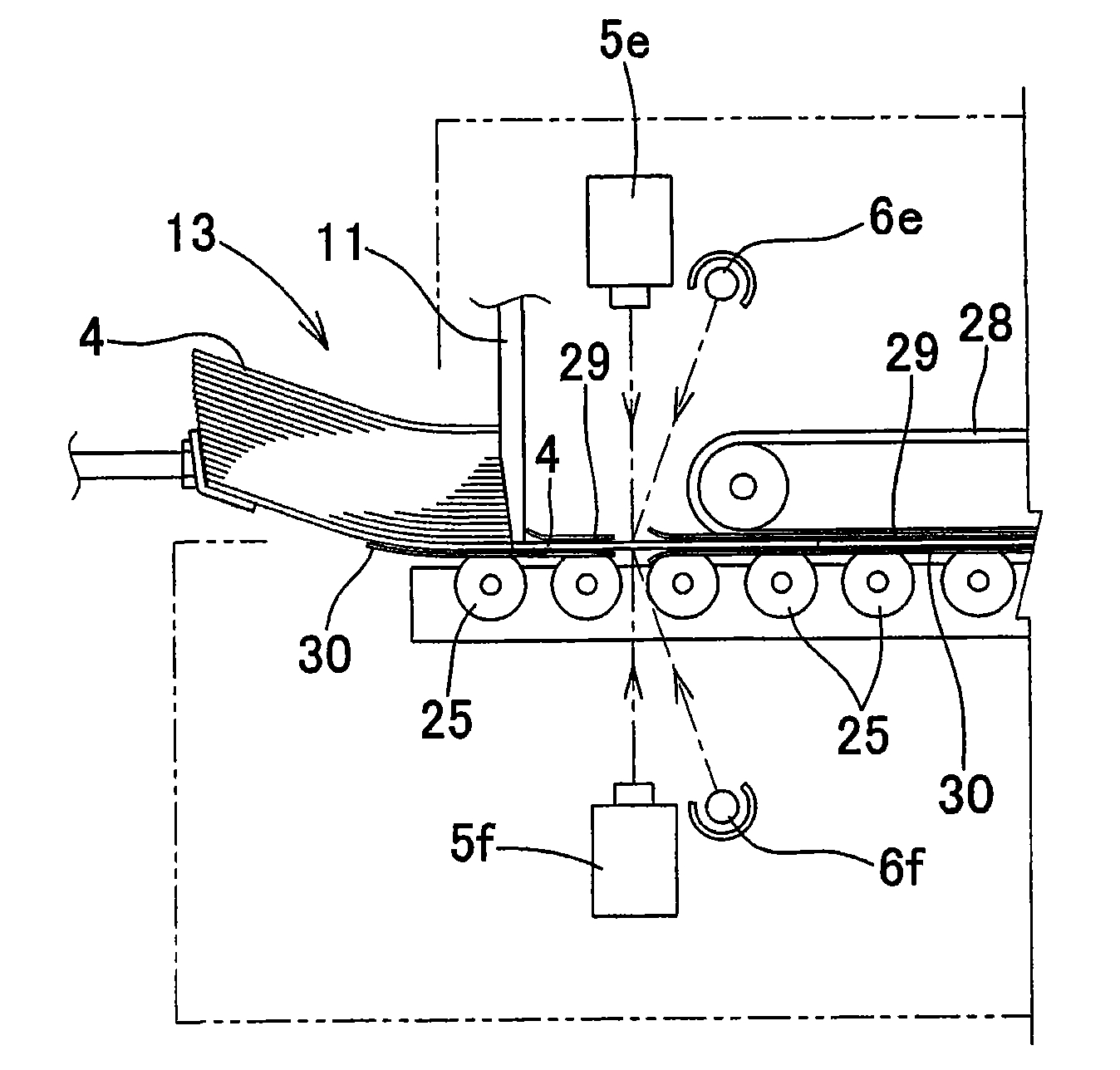

[0039] The box making apparatus of the present invention will be described below with reference to the drawings.

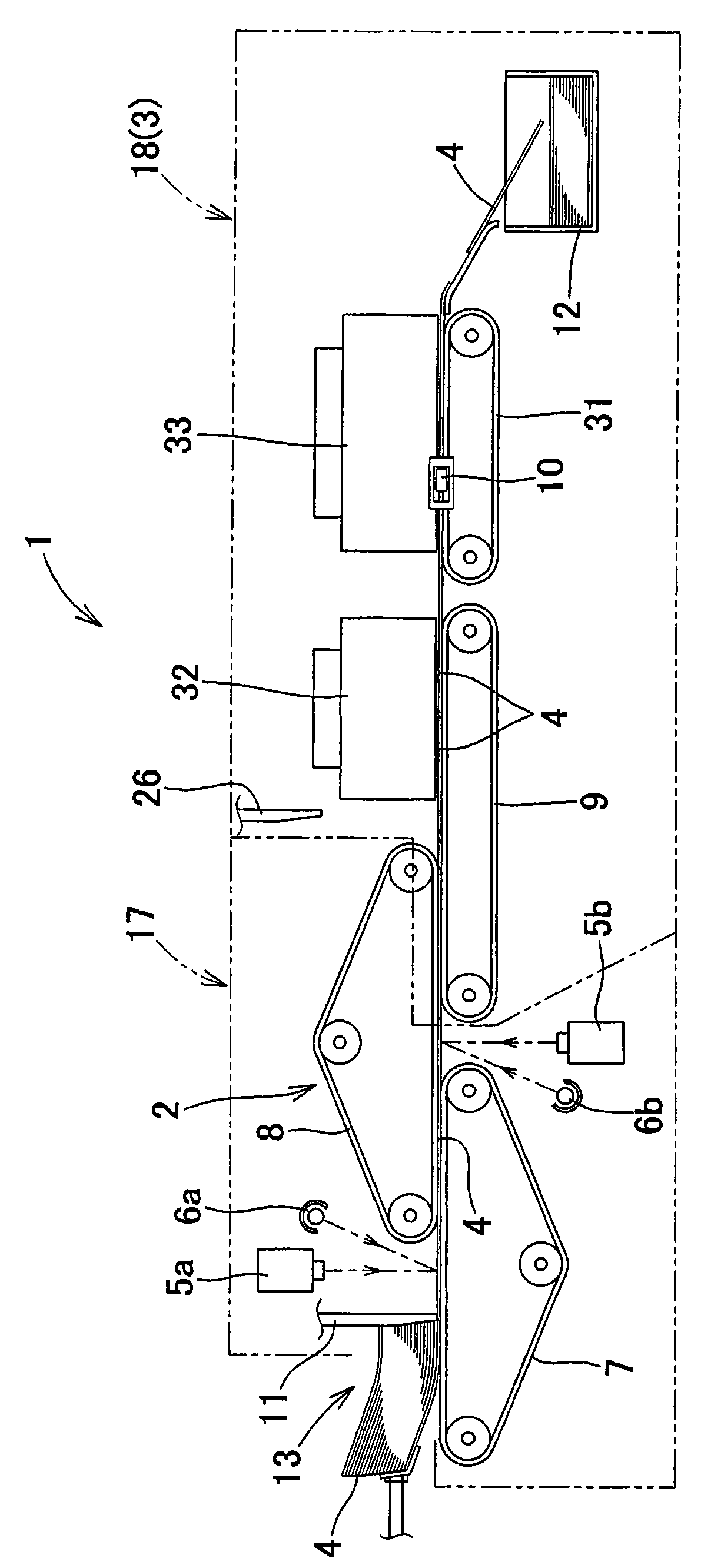

[0040] figure 1 It is a schematic diagram of the box making apparatus 1 in which the inspection unit 17 which unitized the blank inspection part, the paper feeding part 13, and the conveyance part 2 together is installed in the conventional box making device 18.

[0041] In the figure, 1 represents the box-making device, 2 represents the conveying part, 4 represents the blank, 5 represents the camera unit, 6 represents the lighting unit, 7 represents the take-out belt, 8 represents the suction belt, 9 represents the conveyor belt, 10 represents the distinguishing unit, 11 represents the slide Block 12 denotes a stacking section, 13 denotes a paper feeding section, 17 denotes an inspection unit, 18 denotes a conventional cassette-making apparatus, and 26 denotes a slider provided in the conventional cassette-making apparatus.

[0042] The inspection unit 17 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com