Full-automatic heat-transferring banner printer

A thermal transfer printing machine, thermal transfer printing technology, applied in rotary printing machines, printing machines, transfer printing and other directions, can solve the problems of inconvenient operation, high production cost, low efficiency, etc., to improve work efficiency and reduce production costs , to ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

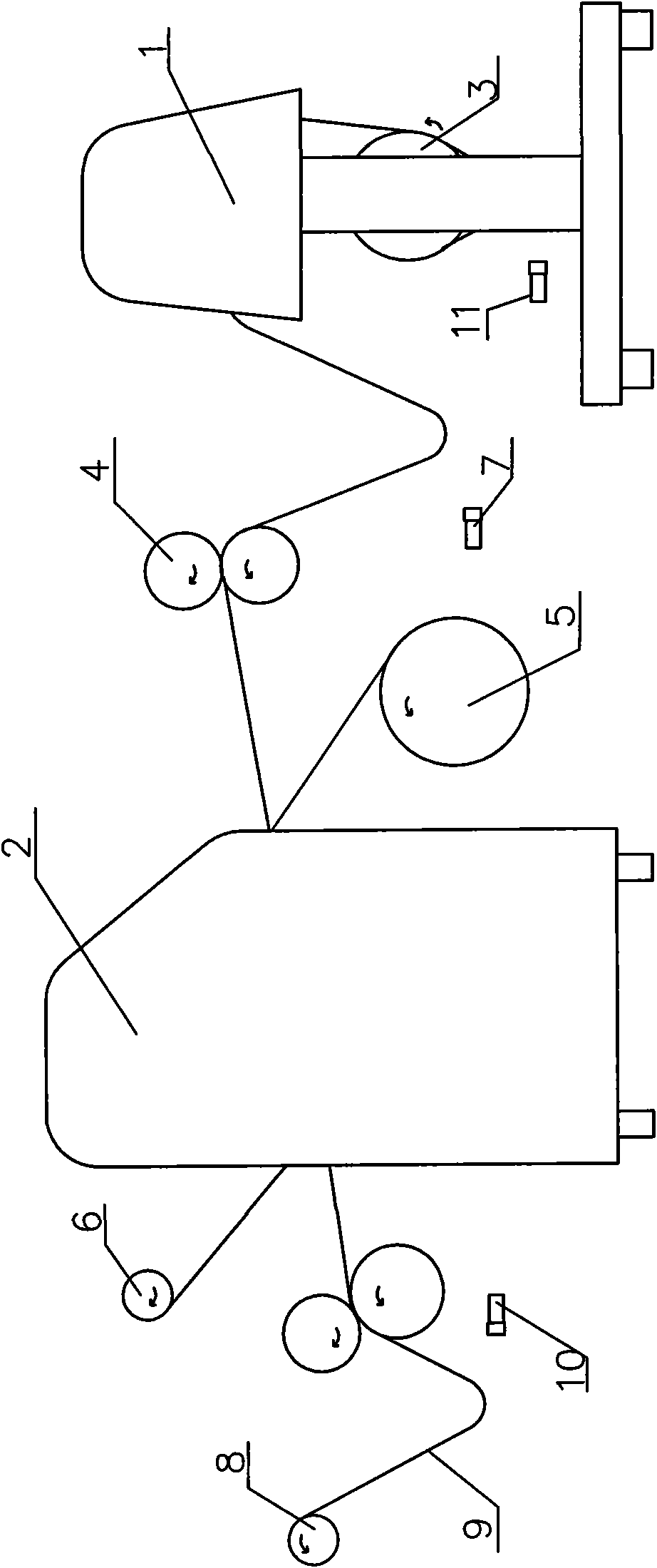

[0008] like figure 1 As shown, a fully automatic thermal transfer banner machine includes a thermal transfer machine 2, a numerically controlled gluing machine 1 is arranged on one side of the thermal transfer machine 2, and a The paper guide roller 4 and the banner cloth roller 5, and the other side of the thermal transfer machine 2 are provided with a paper delivery roller 6 and a cloth delivery roller 8 .

[0009] The working process of the present invention is as follows: first, put the thermal transfer paper 3 into the numerically controlled gluing machine 1, apply a layer of glue on the positions with characters or patterns through computer typesetting control, and after the glue dries, the thermal transfer of the characters or patterns The thermal sublimation powder on the printing paper 3 is solidified, and the thermal transfer paper 3 moves under the action of the paper guide roller 4, and is laminated with the banner cloth 9 and enters the thermal transfer machine 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com