Ship equipped with thermal energy recovery means and related process

A recovery device and ship technology, applied in ship propulsion, propulsion engine, ship construction, etc., to achieve the effect of improving energy balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

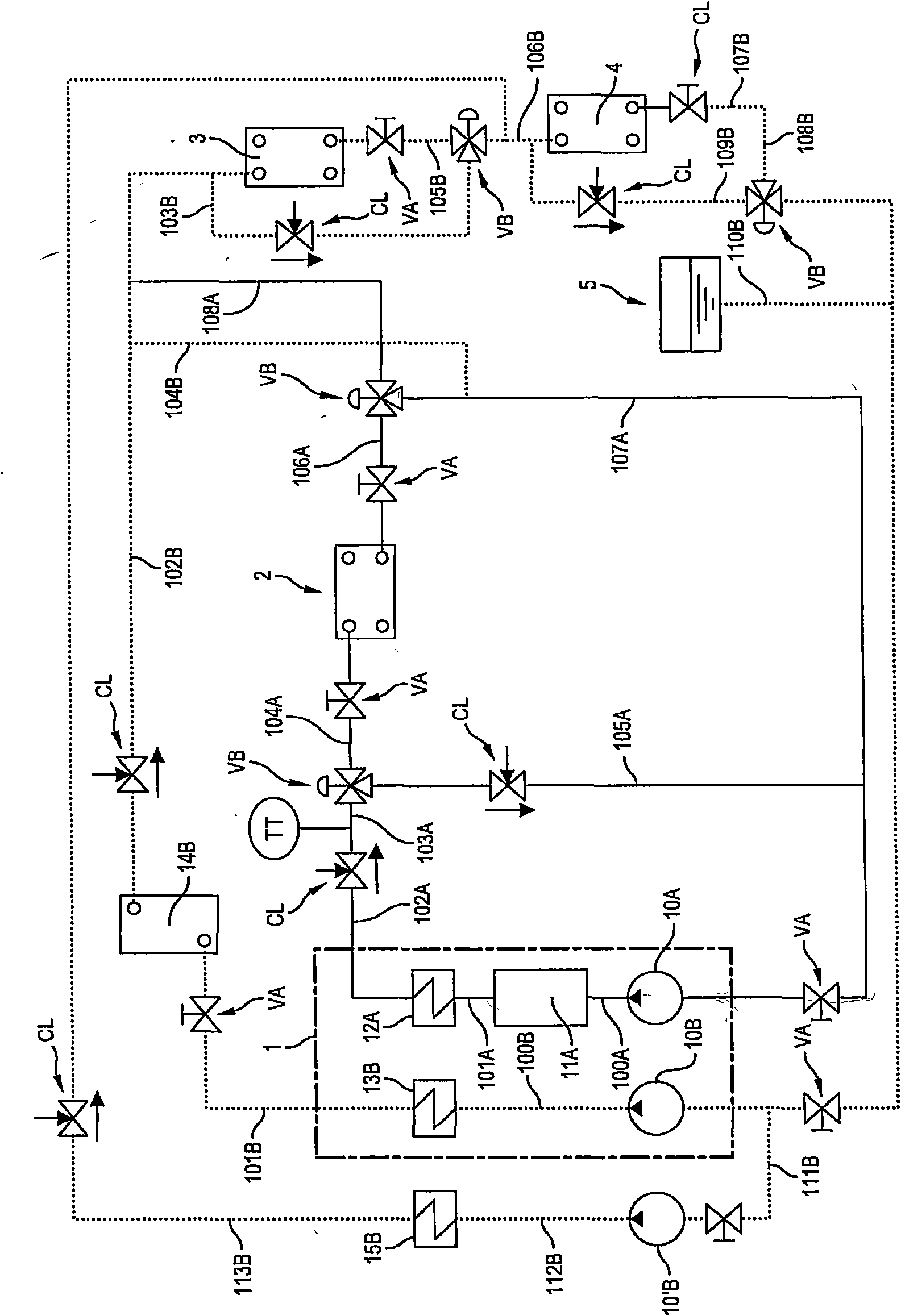

[0035] see figure 1 , the dotted line represents the delimitation of the diesel engine 1 equipped on the ship.

[0036] Obviously, if there are many engines, say 4, then the figure 1 Components in are replicated the same number of times.

[0037] The circulation of the coolant in the so-called high-temperature circuit is shown with solid lines, and the circulation of the coolant in the so-called low-temperature circuit is shown with dashed lines.

[0038] Additionally, equipment located on these two circuits bears a reference number followed by an initial A or B, corresponding to the high temperature circuit and the low temperature circuit, respectively.

[0039] Generally, throughout the description, reference numerals VA, CL, and VB denote a stop valve, a flow control valve, and a three-way regulating valve, respectively.

[0040] see figure 1 , reference numeral 10A denotes a hydraulic pump that ensures circulation of a high-temperature coolant such as water in componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com