Node of connection of column and beam

A joint and joint technology, applied in the field of joints between columns and beams, can solve problems such as increasing structural weight and stiffness, reducing effective use area, increasing building costs, etc., to improve the ability to resist damage and protect people's lives Property safety and the effect of improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

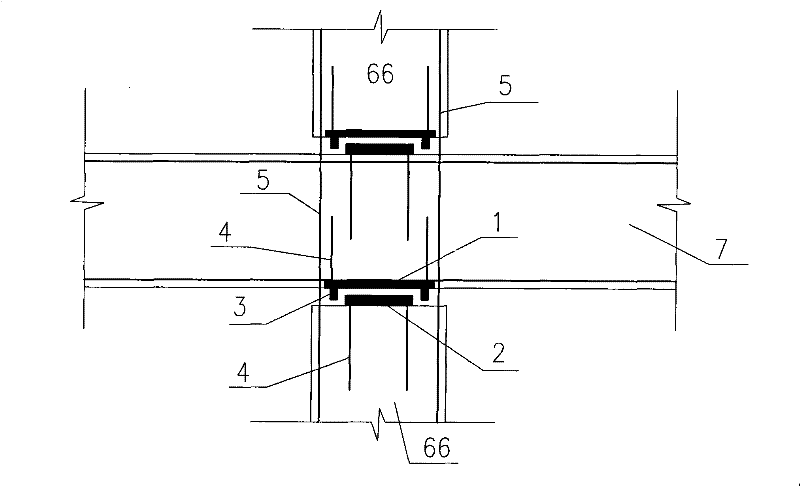

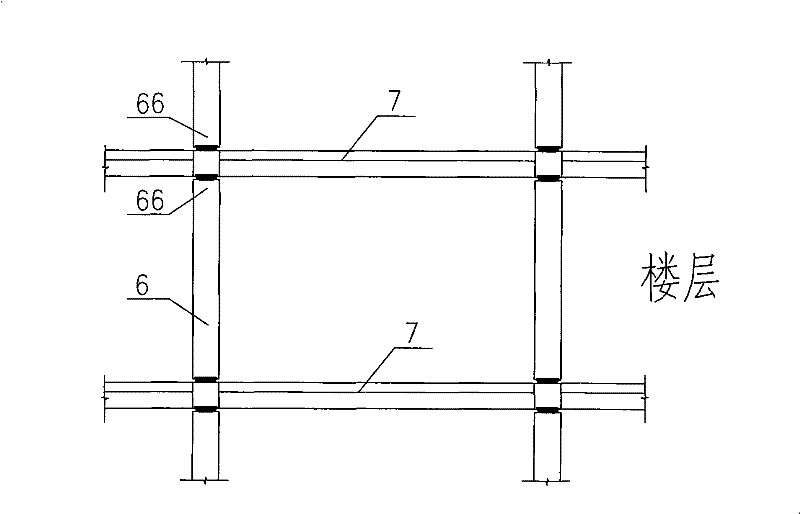

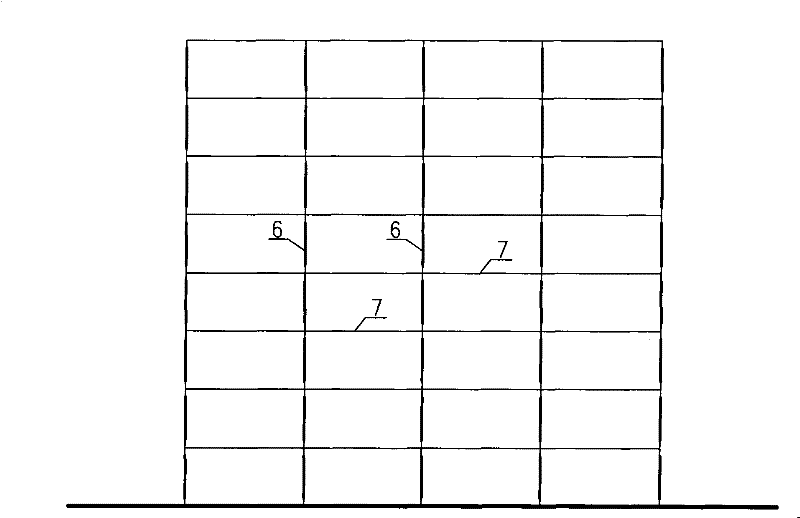

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention is applied to reinforced concrete frame structures. The joint is composed of steel plate 1, steel plate 2 and column reinforcement 5. At the joint between column end 66 and beam plate 7 of the building, two steel plates are placed up and down: steel plate 1 and steel plate 2. The contact area of steel plate 1 and steel plate 2 is smaller than that of the column The cross-sectional area of the end 66 increases the rotation capacity and energy dissipation capacity of the joint. Both the steel plate 1 and the steel plate 2 are fixed with a number of short steel bars 4, and the short steel bars 4 are fixed in the concrete of the column end 66 or the beam plate 7, and the column bars 5 are in two The number of configurations in the steel plate range is less than that of other parts of the column end 66, so that the stiffness and bending resistance of this node are lower than the stiffness and bendi...

Embodiment 2

[0029] Such as Figure 4 , Figure 5 As shown, the present invention is applied to a frame structure provided with diagonal stay rods 8 . The present invention can form a truss-type lateral force-resisting system in conjunction with a frame of diagonal tie rods 8. The two ends of the tie rods 8 are respectively fixed on the beam-column joints 9 of the upper and lower floors. The tie rods 8 can be made of high-strength steel strands or high-strength steel bars. The shear force and bending moment of the column 6 are greatly reduced, and the column 6 mainly bears the axial force, giving full play to the advantages of high compressive strength of the concrete, and improving the bearing capacity of the column 6. Therefore, under the action of an earthquake, the column end 66 will not be damaged, thereby achieving the effect of "strong column and weak beam" required by the code, and greatly improving the seismic performance of the building.

Embodiment 3

[0031] Such as Figure 6 As shown, the present invention is applied to a frame-shear wall structure or a frame-tube structure. Diagonal tie rods 8 can be set in the frame, such as Figure 7 As shown, the two ends of the tie rods 8 are respectively fixed on the beam-column nodes 9 on the upper and lower floors, and can also be anchored at the intersection of the beam plate 7 and the shear wall 10. The tie rods 8 can be made of high-strength steel strands or high-strength steel bars, The hybrid frame and the shear wall 10 form a hybrid lateral force-resistant system, which is suitable for high-rise and super high-rise building structures designed for earthquake resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com